Are you a seasoned Pit Furnace Operator seeking a new career path? Discover our professionally built Pit Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

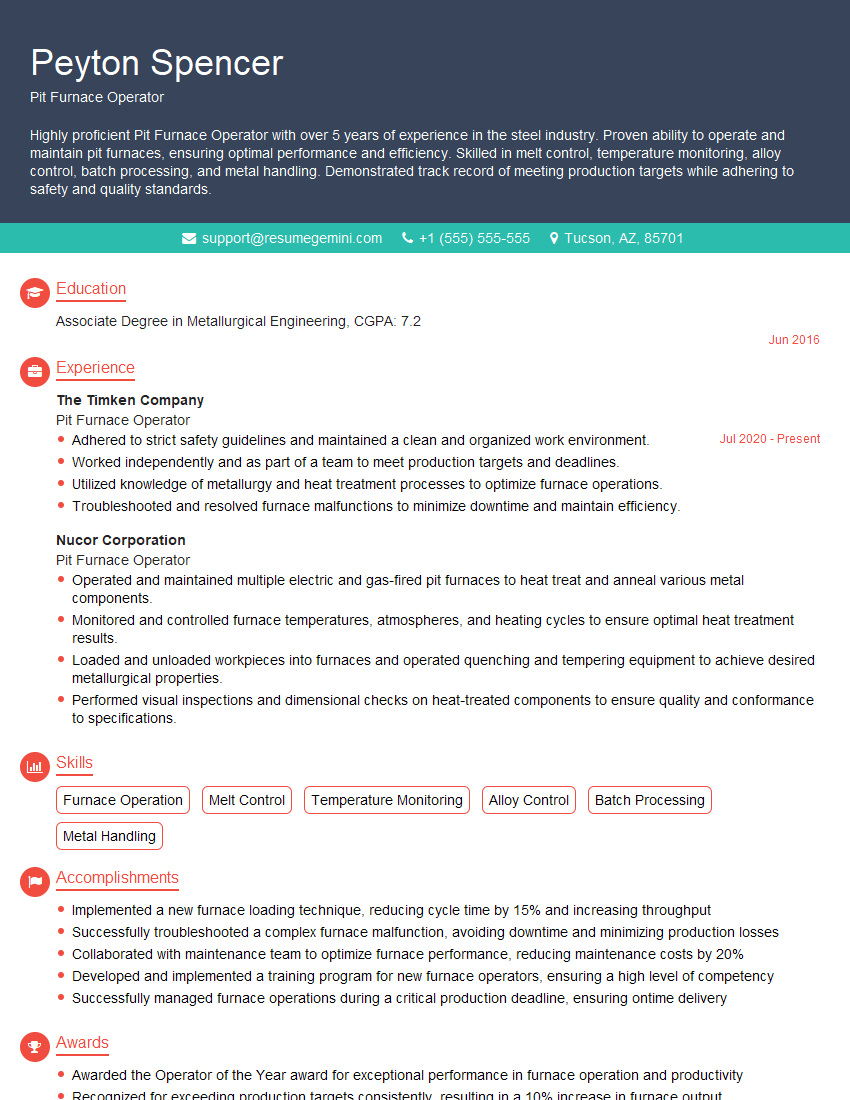

Peyton Spencer

Pit Furnace Operator

Summary

Highly proficient Pit Furnace Operator with over 5 years of experience in the steel industry. Proven ability to operate and maintain pit furnaces, ensuring optimal performance and efficiency. Skilled in melt control, temperature monitoring, alloy control, batch processing, and metal handling. Demonstrated track record of meeting production targets while adhering to safety and quality standards.

Education

Associate Degree in Metallurgical Engineering

June 2016

Skills

- Furnace Operation

- Melt Control

- Temperature Monitoring

- Alloy Control

- Batch Processing

- Metal Handling

Work Experience

Pit Furnace Operator

- Adhered to strict safety guidelines and maintained a clean and organized work environment.

- Worked independently and as part of a team to meet production targets and deadlines.

- Utilized knowledge of metallurgy and heat treatment processes to optimize furnace operations.

- Troubleshooted and resolved furnace malfunctions to minimize downtime and maintain efficiency.

Pit Furnace Operator

- Operated and maintained multiple electric and gas-fired pit furnaces to heat treat and anneal various metal components.

- Monitored and controlled furnace temperatures, atmospheres, and heating cycles to ensure optimal heat treatment results.

- Loaded and unloaded workpieces into furnaces and operated quenching and tempering equipment to achieve desired metallurgical properties.

- Performed visual inspections and dimensional checks on heat-treated components to ensure quality and conformance to specifications.

Accomplishments

- Implemented a new furnace loading technique, reducing cycle time by 15% and increasing throughput

- Successfully troubleshooted a complex furnace malfunction, avoiding downtime and minimizing production losses

- Collaborated with maintenance team to optimize furnace performance, reducing maintenance costs by 20%

- Developed and implemented a training program for new furnace operators, ensuring a high level of competency

- Successfully managed furnace operations during a critical production deadline, ensuring ontime delivery

Awards

- Awarded the Operator of the Year award for exceptional performance in furnace operation and productivity

- Recognized for exceeding production targets consistently, resulting in a 10% increase in furnace output

- Received the Safety Star award for maintaining an exemplary safety record and adhering to all protocols

- Awarded for implementing innovative furnace control strategies, leading to improved product quality

Certificates

- Certified Pit Furnace Operator (CPFO)

- National Association of Surface Finishers (NASF)

- American Foundry Society (AFS)

- OSHA 30-Hour Hazardous Waste Operations and Emergency Response (HAZWOPER)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pit Furnace Operator

- Quantify your accomplishments using specific metrics and data whenever possible.

- Highlight your experience in specific furnace types and processes relevant to the job you’re applying for.

- Emphasize your knowledge of metallurgy and materials science, and how it applies to your work as a Pit Furnace Operator.

- Demonstrate your commitment to safety and quality by highlighting your adherence to industry standards and best practices.

- consider obtaining industry-recognized certifications, such as the Certified Pit Furnace Operator (CPFO) credential.

Essential Experience Highlights for a Strong Pit Furnace Operator Resume

- Operate and maintain pit furnaces to melt and refine ferrous and non-ferrous metals.

- Monitor and control furnace temperatures, gas flow, and other process parameters to achieve desired alloy composition and properties.

- Adjust alloy compositions by adding specified materials to the molten metal.

- Control batch processing operations, including charging, holding, and tapping molten metal.

- Handle and transport molten metal safely and efficiently using cranes, ladles, and other equipment.

- Inspect furnaces and equipment regularly to identify potential problems and ensure proper functioning.

- Maintain accurate records of furnace operations and process parameters for quality control and traceability.

Frequently Asked Questions (FAQ’s) For Pit Furnace Operator

What is the primary role of a Pit Furnace Operator?

Pit Furnace Operators are responsible for operating and maintaining pit furnaces to melt and refine ferrous and non-ferrous metals. They ensure that the furnace is operating safely and efficiently, and that the metal is melted to the correct specifications.

What are the key skills required for a Pit Furnace Operator?

Pit Furnace Operators should have a strong understanding of metallurgy and materials science, as well as experience in operating and maintaining furnaces. They should also be proficient in melt control, temperature monitoring, alloy control, batch processing, and metal handling. Safety is also of utmost importance, so Pit Furnace Operators must be familiar with all relevant safety regulations.

What are the common industries that employ Pit Furnace Operators?

Pit Furnace Operators are employed in a variety of industries, including steel mills, foundries, and metalworking shops. They are responsible for melting and refining metals used in a wide range of products, from cars to construction materials.

What is the average salary for a Pit Furnace Operator?

The average salary for a Pit Furnace Operator in the United States is around $60,000 per year. However, salaries can vary depending on experience, location, and industry.

What are the career advancement opportunities for a Pit Furnace Operator?

With experience and additional training, Pit Furnace Operators can advance to positions such as Furnace Supervisor, Melt Shop Manager, or even Plant Manager. They can also specialize in specific areas, such as alloy development or heat treatment.

How can I become a Pit Furnace Operator?

To become a Pit Furnace Operator, you typically need a high school diploma or equivalent. Some employers may require an associate degree or certification in metallurgy or a related field. You can gain experience by working as a furnace helper or in a related position.

What are the safety precautions that Pit Furnace Operators must follow?

Pit Furnace Operators must follow all safety regulations and procedures to minimize the risk of accidents. They must wear appropriate personal protective equipment, such as gloves, safety glasses, and a hard hat. They must also be aware of the potential hazards of working with molten metal, such as burns and explosions.

What is the future outlook for Pit Furnace Operators?

The future outlook for Pit Furnace Operators is expected to be positive. As the demand for metal products continues to grow, so will the need for qualified Pit Furnace Operators.