Are you a seasoned Planer Type Milling Machine Set-Up Operator seeking a new career path? Discover our professionally built Planer Type Milling Machine Set-Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

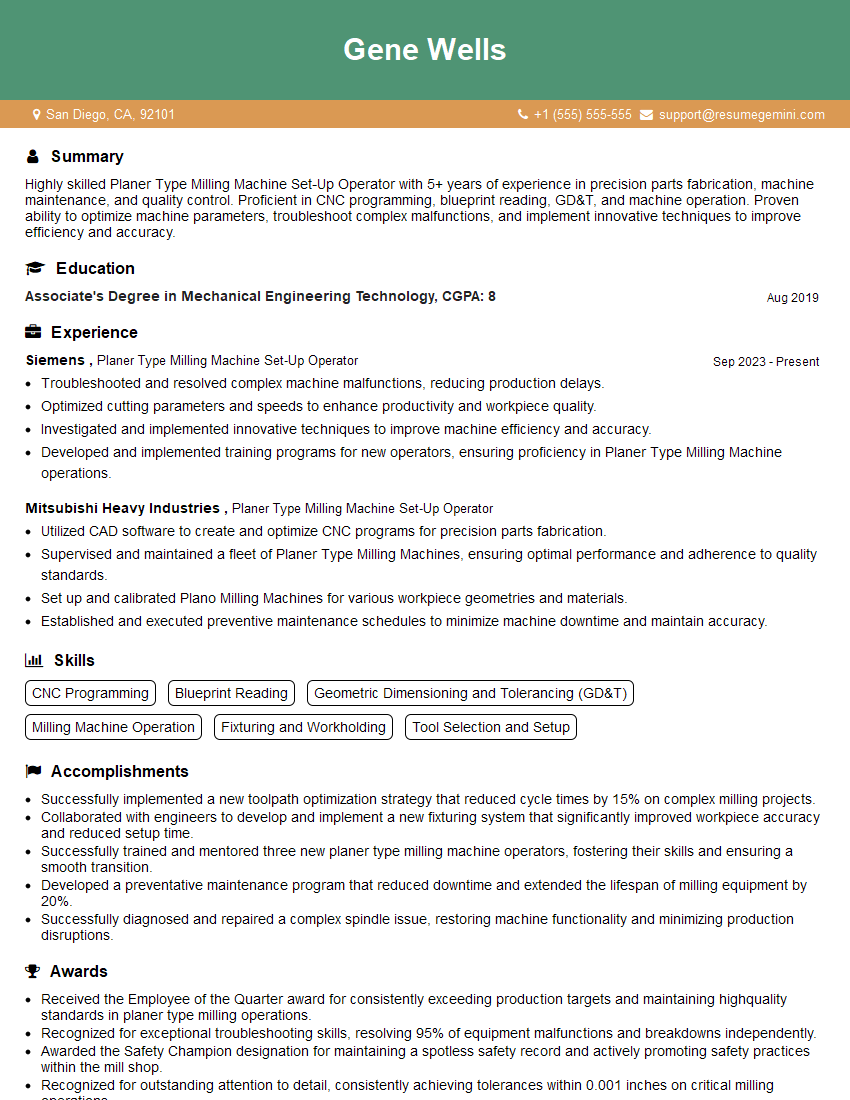

Gene Wells

Planer Type Milling Machine Set-Up Operator

Summary

Highly skilled Planer Type Milling Machine Set-Up Operator with 5+ years of experience in precision parts fabrication, machine maintenance, and quality control. Proficient in CNC programming, blueprint reading, GD&T, and machine operation. Proven ability to optimize machine parameters, troubleshoot complex malfunctions, and implement innovative techniques to improve efficiency and accuracy.

Education

Associate’s Degree in Mechanical Engineering Technology

August 2019

Skills

- CNC Programming

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

- Milling Machine Operation

- Fixturing and Workholding

- Tool Selection and Setup

Work Experience

Planer Type Milling Machine Set-Up Operator

- Troubleshooted and resolved complex machine malfunctions, reducing production delays.

- Optimized cutting parameters and speeds to enhance productivity and workpiece quality.

- Investigated and implemented innovative techniques to improve machine efficiency and accuracy.

- Developed and implemented training programs for new operators, ensuring proficiency in Planer Type Milling Machine operations.

Planer Type Milling Machine Set-Up Operator

- Utilized CAD software to create and optimize CNC programs for precision parts fabrication.

- Supervised and maintained a fleet of Planer Type Milling Machines, ensuring optimal performance and adherence to quality standards.

- Set up and calibrated Plano Milling Machines for various workpiece geometries and materials.

- Established and executed preventive maintenance schedules to minimize machine downtime and maintain accuracy.

Accomplishments

- Successfully implemented a new toolpath optimization strategy that reduced cycle times by 15% on complex milling projects.

- Collaborated with engineers to develop and implement a new fixturing system that significantly improved workpiece accuracy and reduced setup time.

- Successfully trained and mentored three new planer type milling machine operators, fostering their skills and ensuring a smooth transition.

- Developed a preventative maintenance program that reduced downtime and extended the lifespan of milling equipment by 20%.

- Successfully diagnosed and repaired a complex spindle issue, restoring machine functionality and minimizing production disruptions.

Awards

- Received the Employee of the Quarter award for consistently exceeding production targets and maintaining highquality standards in planer type milling operations.

- Recognized for exceptional troubleshooting skills, resolving 95% of equipment malfunctions and breakdowns independently.

- Awarded the Safety Champion designation for maintaining a spotless safety record and actively promoting safety practices within the mill shop.

- Recognized for outstanding attention to detail, consistently achieving tolerances within 0.001 inches on critical milling operations.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- CNC Programming Certification

- GD&T Certification

- CMM Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Planer Type Milling Machine Set-Up Operator

- Highlight your experience in operating and maintaining Planer Type Milling Machines.

- Showcase your proficiency in CNC programming and GD&T.

- Quantify your accomplishments with specific metrics, such as reducing machine downtime or improving workpiece quality.

- Emphasize your ability to troubleshoot complex machine malfunctions and implement innovative solutions.

Essential Experience Highlights for a Strong Planer Type Milling Machine Set-Up Operator Resume

- Utilized CAD software to create and optimize CNC programs for precision parts fabrication

- Supervised and maintained a fleet of Planer Type Milling Machines, ensuring optimal performance and adherence to quality standards

- Set up and calibrated Plano Milling Machines for various workpiece geometries and materials

- Established and executed preventive maintenance schedules to minimize machine downtime and maintain accuracy

- Troubleshooted and resolved complex machine malfunctions, reducing production delays

- Optimized cutting parameters and speeds to enhance productivity and workpiece quality

- Investigated and implemented innovative techniques to improve machine efficiency and accuracy

Frequently Asked Questions (FAQ’s) For Planer Type Milling Machine Set-Up Operator

What is the role of a Planer Type Milling Machine Set-Up Operator?

A Planer Type Milling Machine Set-Up Operator is responsible for setting up, calibrating, and operating Planer Type Milling Machines to produce precision parts according to design specifications. They also perform preventive maintenance, troubleshoot malfunctions, and implement improvements to enhance machine efficiency and accuracy.

What skills are required to be a Planer Type Milling Machine Set-Up Operator?

Required skills include CNC programming, blueprint reading, GD&T, milling machine operation, fixturing and workholding, tool selection and setup, and mechanical aptitude.

What is the work environment of a Planer Type Milling Machine Set-Up Operator?

Planer Type Milling Machine Set-Up Operators typically work in a manufacturing environment, operating machines in a workshop or factory setting. They may work with other operators, machinists, and engineers to ensure the smooth production of parts.

What are the career prospects for a Planer Type Milling Machine Set-Up Operator?

Experienced Planer Type Milling Machine Set-Up Operators can advance to supervisory or management roles, or specialize in specific areas such as CNC programming or machine maintenance. They may also pursue further education or training to enhance their skills and knowledge.

What is the salary range for a Planer Type Milling Machine Set-Up Operator?

The salary range for a Planer Type Milling Machine Set-Up Operator varies depending on factors such as experience, location, and industry. According to Indeed, the average salary for a Milling Machine Operator in the United States is around $22 per hour.

What are the benefits of working as a Planer Type Milling Machine Set-Up Operator?

Benefits of working as a Planer Type Milling Machine Set-Up Operator include job security, opportunities for advancement, and the satisfaction of working with precision machinery to produce high-quality parts.

What are the challenges of working as a Planer Type Milling Machine Set-Up Operator?

Challenges of working as a Planer Type Milling Machine Set-Up Operator include working with heavy machinery, potential for noise and dust exposure, and the need for continuous learning and skill development to keep up with technological advancements.

What is the future of the Planer Type Milling Machine Set-Up Operator profession?

The future of the Planer Type Milling Machine Set-Up Operator profession is expected to be stable, as the demand for precision-machined parts continues to grow across various industries. However, technological advancements such as automation and robotics may impact the job market, requiring operators to adapt and embrace new skills.