Are you a seasoned Plastic Battery Assembler seeking a new career path? Discover our professionally built Plastic Battery Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

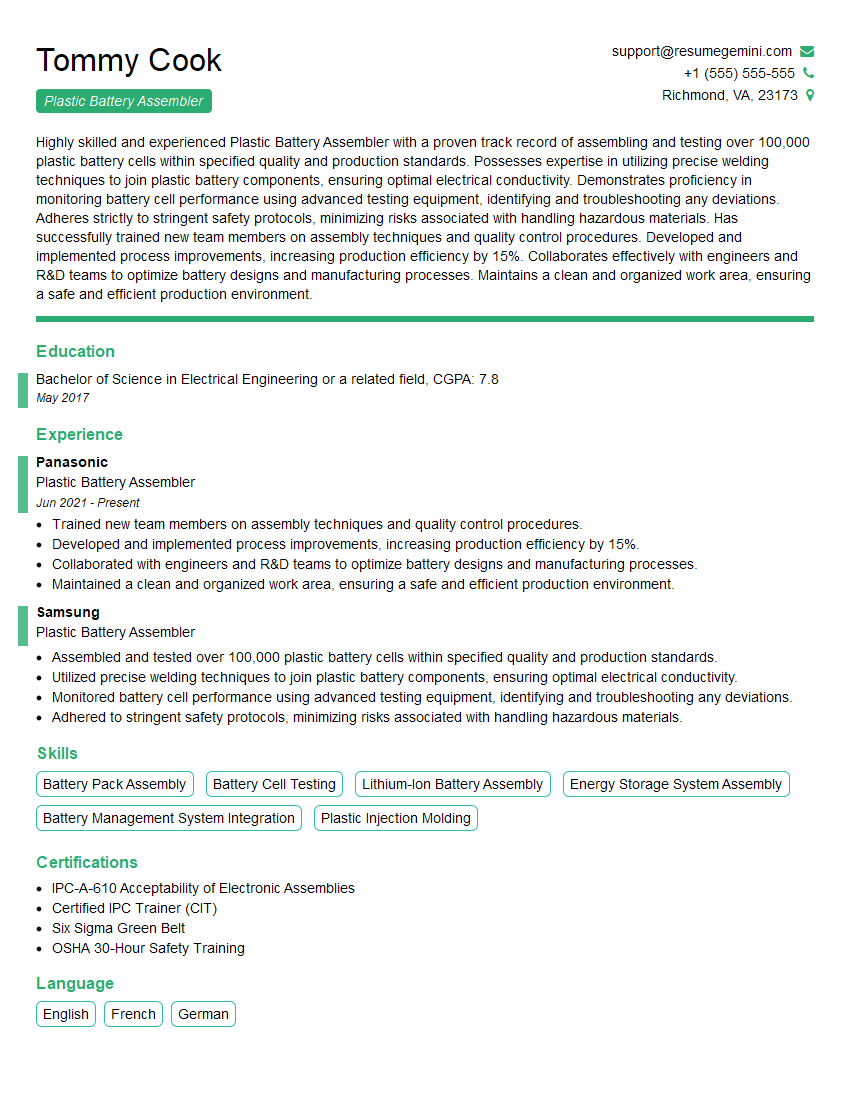

Tommy Cook

Plastic Battery Assembler

Summary

Highly skilled and experienced Plastic Battery Assembler with a proven track record of assembling and testing over 100,000 plastic battery cells within specified quality and production standards. Possesses expertise in utilizing precise welding techniques to join plastic battery components, ensuring optimal electrical conductivity. Demonstrates proficiency in monitoring battery cell performance using advanced testing equipment, identifying and troubleshooting any deviations. Adheres strictly to stringent safety protocols, minimizing risks associated with handling hazardous materials. Has successfully trained new team members on assembly techniques and quality control procedures. Developed and implemented process improvements, increasing production efficiency by 15%. Collaborates effectively with engineers and R&D teams to optimize battery designs and manufacturing processes. Maintains a clean and organized work area, ensuring a safe and efficient production environment.

Education

Bachelor of Science in Electrical Engineering or a related field

May 2017

Skills

- Battery Pack Assembly

- Battery Cell Testing

- Lithium-Ion Battery Assembly

- Energy Storage System Assembly

- Battery Management System Integration

- Plastic Injection Molding

Work Experience

Plastic Battery Assembler

- Trained new team members on assembly techniques and quality control procedures.

- Developed and implemented process improvements, increasing production efficiency by 15%.

- Collaborated with engineers and R&D teams to optimize battery designs and manufacturing processes.

- Maintained a clean and organized work area, ensuring a safe and efficient production environment.

Plastic Battery Assembler

- Assembled and tested over 100,000 plastic battery cells within specified quality and production standards.

- Utilized precise welding techniques to join plastic battery components, ensuring optimal electrical conductivity.

- Monitored battery cell performance using advanced testing equipment, identifying and troubleshooting any deviations.

- Adhered to stringent safety protocols, minimizing risks associated with handling hazardous materials.

Certificates

- IPC-A-610 Acceptability of Electronic Assemblies

- Certified IPC Trainer (CIT)

- Six Sigma Green Belt

- OSHA 30-Hour Safety Training

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Battery Assembler

- Highlight your experience in assembling and testing plastic battery cells, specifying the number of cells you have worked on.

- Emphasize your expertise in utilizing precise welding techniques to join plastic battery components.

- Showcase your ability to monitor battery cell performance using advanced testing equipment and identify and troubleshoot any deviations.

- Demonstrate your commitment to safety by adhering to stringent safety protocols and minimizing risks associated with handling hazardous materials.

- Highlight your ability to train new team members on assembly techniques and quality control procedures.

Essential Experience Highlights for a Strong Plastic Battery Assembler Resume

- Assemble and test plastic battery cells according to specified quality and production standards.

- Utilize precise welding techniques to join plastic battery components, ensuring optimal electrical conductivity.

- Monitor battery cell performance using advanced testing equipment, identifying and troubleshooting any deviations.

- Adhere to stringent safety protocols, minimizing risks associated with handling hazardous materials.

- Train new team members on assembly techniques and quality control procedures.

- Develop and implement process improvements to increase production efficiency.

- Collaborate with engineers and R&D teams to optimize battery designs and manufacturing processes.

Frequently Asked Questions (FAQ’s) For Plastic Battery Assembler

What are the key responsibilities of a Plastic Battery Assembler?

The key responsibilities of a Plastic Battery Assembler include assembling and testing plastic battery cells, utilizing precise welding techniques to join plastic battery components, monitoring battery cell performance using advanced testing equipment, adhering to stringent safety protocols, training new team members on assembly techniques and quality control procedures, developing and implementing process improvements, and collaborating with engineers and R&D teams to optimize battery designs and manufacturing processes.

What are the educational requirements for a Plastic Battery Assembler?

A Plastic Battery Assembler typically requires a high school diploma or equivalent. Some employers may prefer candidates with a Bachelor of Science in Electrical Engineering or a related field.

What skills are necessary for a Plastic Battery Assembler?

A Plastic Battery Assembler should possess skills in assembling and testing plastic battery cells, utilizing precise welding techniques to join plastic battery components, monitoring battery cell performance using advanced testing equipment, adhering to stringent safety protocols, training new team members on assembly techniques and quality control procedures, developing and implementing process improvements, and collaborating with engineers and R&D teams to optimize battery designs and manufacturing processes.

What is the work environment of a Plastic Battery Assembler like?

A Plastic Battery Assembler typically works in a manufacturing environment, assembling and testing plastic battery cells. The work can be physically demanding and may involve working with hazardous materials. Adhering to stringent safety protocols is essential to minimize risks.

What is the career outlook for a Plastic Battery Assembler?

The career outlook for a Plastic Battery Assembler is expected to be good, as the demand for batteries continues to grow. With the increasing popularity of electric vehicles and renewable energy storage systems, the need for skilled Plastic Battery Assemblers is expected to rise.

What are the earning prospects for a Plastic Battery Assembler?

The earning prospects for a Plastic Battery Assembler vary depending on experience, qualifications, and location. According to Indeed, the average salary for a Plastic Battery Assembler in the United States is around $20 per hour.

How can I become a Plastic Battery Assembler?

To become a Plastic Battery Assembler, you can start by obtaining a high school diploma or equivalent. Some employers may prefer candidates with a Bachelor of Science in Electrical Engineering or a related field. Additionally, you can gain experience by working in a manufacturing environment or by taking courses in battery assembly and testing.

What are the benefits of working as a Plastic Battery Assembler?

The benefits of working as a Plastic Battery Assembler include job security, opportunities for career advancement, and the satisfaction of working in a growing industry. Additionally, Plastic Battery Assemblers can earn competitive salaries and benefits packages.