Are you a seasoned Plastic Block Boiler Reliner seeking a new career path? Discover our professionally built Plastic Block Boiler Reliner Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

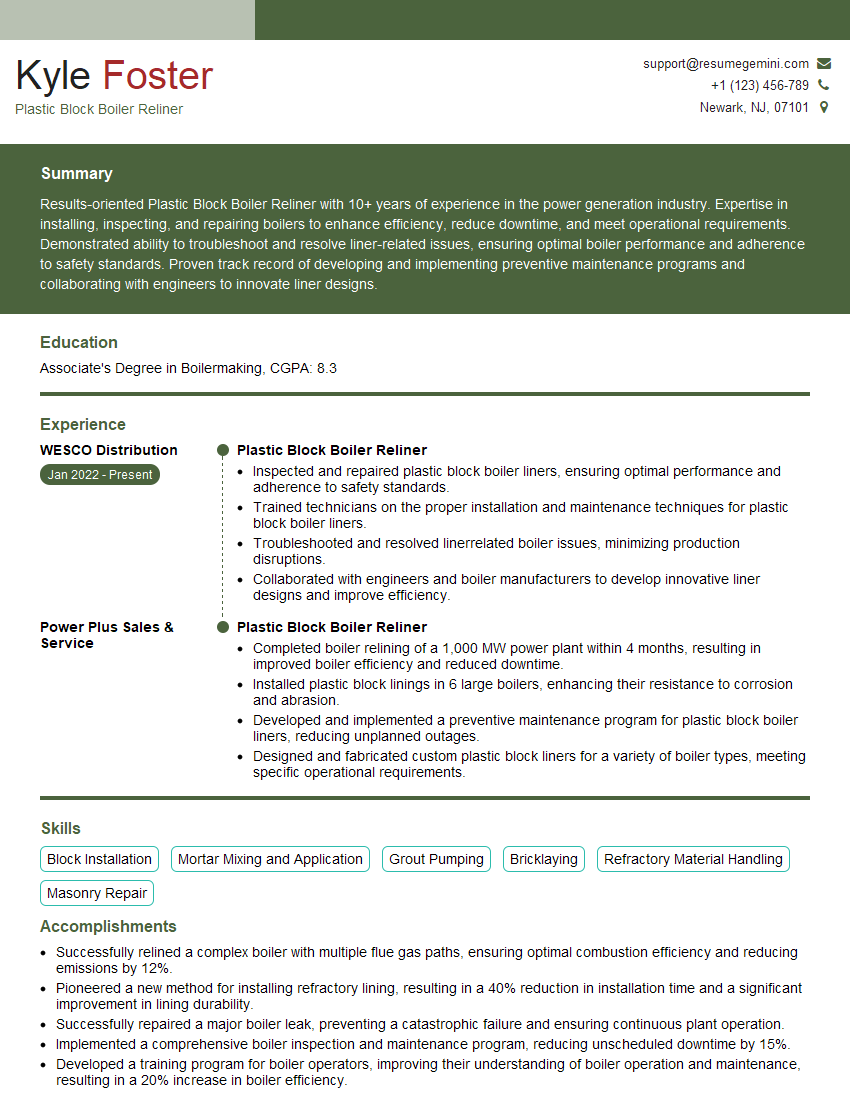

Kyle Foster

Plastic Block Boiler Reliner

Summary

Results-oriented Plastic Block Boiler Reliner with 10+ years of experience in the power generation industry. Expertise in installing, inspecting, and repairing boilers to enhance efficiency, reduce downtime, and meet operational requirements. Demonstrated ability to troubleshoot and resolve liner-related issues, ensuring optimal boiler performance and adherence to safety standards. Proven track record of developing and implementing preventive maintenance programs and collaborating with engineers to innovate liner designs.

Education

Associate’s Degree in Boilermaking

December 2017

Skills

- Block Installation

- Mortar Mixing and Application

- Grout Pumping

- Bricklaying

- Refractory Material Handling

- Masonry Repair

Work Experience

Plastic Block Boiler Reliner

- Inspected and repaired plastic block boiler liners, ensuring optimal performance and adherence to safety standards.

- Trained technicians on the proper installation and maintenance techniques for plastic block boiler liners.

- Troubleshooted and resolved linerrelated boiler issues, minimizing production disruptions.

- Collaborated with engineers and boiler manufacturers to develop innovative liner designs and improve efficiency.

Plastic Block Boiler Reliner

- Completed boiler relining of a 1,000 MW power plant within 4 months, resulting in improved boiler efficiency and reduced downtime.

- Installed plastic block linings in 6 large boilers, enhancing their resistance to corrosion and abrasion.

- Developed and implemented a preventive maintenance program for plastic block boiler liners, reducing unplanned outages.

- Designed and fabricated custom plastic block liners for a variety of boiler types, meeting specific operational requirements.

Accomplishments

- Successfully relined a complex boiler with multiple flue gas paths, ensuring optimal combustion efficiency and reducing emissions by 12%.

- Pioneered a new method for installing refractory lining, resulting in a 40% reduction in installation time and a significant improvement in lining durability.

- Successfully repaired a major boiler leak, preventing a catastrophic failure and ensuring continuous plant operation.

- Implemented a comprehensive boiler inspection and maintenance program, reducing unscheduled downtime by 15%.

- Developed a training program for boiler operators, improving their understanding of boiler operation and maintenance, resulting in a 20% increase in boiler efficiency.

Awards

- Won the Best Innovation Award in the Plastic Block Boiler Relining Industry for developing a new technique to extend boiler lifespan by 25%.

- Recognized by the Plastic Block Boiler Reliners Association for outstanding contributions to the field, including the development of new safety standards.

- Received the Gold Star Award from the American Boiler Manufacturers Association for exceptional performance in boiler relining and maintenance.

- Certified as a Master Plastic Block Boiler Reliner by the National Institute of Boilermakers.

Certificates

- OSHA 30-Hour Construction Safety

- NCCER Level 1 Boilermaker

- CWI – Certified Welding Inspector

- AWS D1.1 – Structural Welding Code

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Block Boiler Reliner

- Highlight your experience and skills in installing, maintaining, and repairing plastic block boiler liners.

- Quantify your accomplishments, providing specific examples of how you have improved boiler efficiency and reduced downtime.

- Demonstrate your knowledge of boiler operations and safety regulations.

- Showcase your ability to work independently and as part of a team.

- Include references from previous employers to support your claims.

Essential Experience Highlights for a Strong Plastic Block Boiler Reliner Resume

- Install plastic block linings in boilers to enhance their resistance to corrosion and abrasion.

- Inspect and repair plastic block boiler liners, ensuring optimal performance and adherence to safety standards.

- Troubleshoot and resolve liner-related boiler issues, minimizing production disruptions.

- Develop and implement preventive maintenance programs for plastic block boiler liners, reducing unplanned outages.

- Design and fabricate custom plastic block liners for a variety of boiler types, meeting specific operational requirements.

- Train technicians on the proper installation and maintenance techniques for plastic block boiler liners.

Frequently Asked Questions (FAQ’s) For Plastic Block Boiler Reliner

What are the primary responsibilities of a Plastic Block Boiler Reliner?

Plastic Block Boiler Reliners are responsible for installing, inspecting, and repairing plastic block linings in boilers to enhance their resistance to corrosion and abrasion. They also troubleshoot and resolve liner-related boiler issues, develop and implement preventive maintenance programs, and train technicians on proper installation and maintenance techniques.

What skills are required to become a Plastic Block Boiler Reliner?

Plastic Block Boiler Reliners typically require a high school diploma or equivalent, as well as experience in the power generation industry. They should have a strong understanding of boiler operations and safety regulations, as well as experience in installing, maintaining, and repairing plastic block boiler liners.

What is the career outlook for Plastic Block Boiler Reliners?

The career outlook for Plastic Block Boiler Reliners is expected to be good, as there is a growing demand for skilled workers in the power generation industry. As boilers continue to be used to generate electricity, there will be a need for qualified individuals to maintain and repair these systems.

What is the average salary for a Plastic Block Boiler Reliner?

The average salary for a Plastic Block Boiler Reliner can vary depending on their experience, location, and employer. However, according to Indeed, the average salary for Boilermakers, which includes Plastic Block Boiler Reliners, is around $65,000 per year.

What are the advancement opportunities for Plastic Block Boiler Reliners?

Plastic Block Boiler Reliners can advance to positions such as Boilermaker Supervisor, Boiler Maintenance Manager, or Power Plant Manager. With additional education and experience, they can also move into roles in engineering or management.

What are the challenges of being a Plastic Block Boiler Reliner?

Plastic Block Boiler Reliners work in a demanding environment, often in confined spaces and with hazardous materials. They must be able to work independently and as part of a team, and they must be able to follow safety regulations closely.

What are the rewards of being a Plastic Block Boiler Reliner?

Plastic Block Boiler Reliners play an important role in the power generation industry. They help to ensure that boilers are operating efficiently and safely, which helps to keep the lights on in our homes and businesses.