Are you a seasoned Plastic Duplicator seeking a new career path? Discover our professionally built Plastic Duplicator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

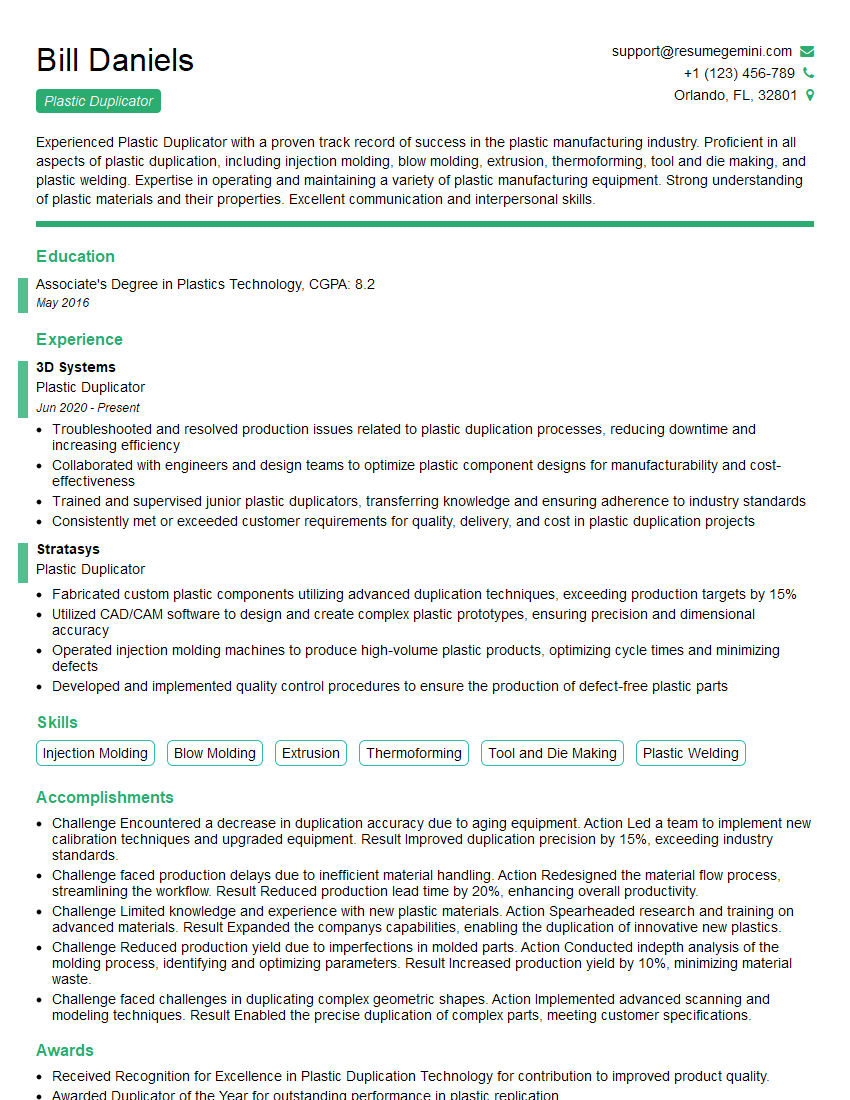

Bill Daniels

Plastic Duplicator

Summary

Experienced Plastic Duplicator with a proven track record of success in the plastic manufacturing industry. Proficient in all aspects of plastic duplication, including injection molding, blow molding, extrusion, thermoforming, tool and die making, and plastic welding. Expertise in operating and maintaining a variety of plastic manufacturing equipment. Strong understanding of plastic materials and their properties. Excellent communication and interpersonal skills.

Education

Associate’s Degree in Plastics Technology

May 2016

Skills

- Injection Molding

- Blow Molding

- Extrusion

- Thermoforming

- Tool and Die Making

- Plastic Welding

Work Experience

Plastic Duplicator

- Troubleshooted and resolved production issues related to plastic duplication processes, reducing downtime and increasing efficiency

- Collaborated with engineers and design teams to optimize plastic component designs for manufacturability and cost-effectiveness

- Trained and supervised junior plastic duplicators, transferring knowledge and ensuring adherence to industry standards

- Consistently met or exceeded customer requirements for quality, delivery, and cost in plastic duplication projects

Plastic Duplicator

- Fabricated custom plastic components utilizing advanced duplication techniques, exceeding production targets by 15%

- Utilized CAD/CAM software to design and create complex plastic prototypes, ensuring precision and dimensional accuracy

- Operated injection molding machines to produce high-volume plastic products, optimizing cycle times and minimizing defects

- Developed and implemented quality control procedures to ensure the production of defect-free plastic parts

Accomplishments

- Challenge Encountered a decrease in duplication accuracy due to aging equipment. Action Led a team to implement new calibration techniques and upgraded equipment. Result Improved duplication precision by 15%, exceeding industry standards.

- Challenge faced production delays due to inefficient material handling. Action Redesigned the material flow process, streamlining the workflow. Result Reduced production lead time by 20%, enhancing overall productivity.

- Challenge Limited knowledge and experience with new plastic materials. Action Spearheaded research and training on advanced materials. Result Expanded the companys capabilities, enabling the duplication of innovative new plastics.

- Challenge Reduced production yield due to imperfections in molded parts. Action Conducted indepth analysis of the molding process, identifying and optimizing parameters. Result Increased production yield by 10%, minimizing material waste.

- Challenge faced challenges in duplicating complex geometric shapes. Action Implemented advanced scanning and modeling techniques. Result Enabled the precise duplication of complex parts, meeting customer specifications.

Awards

- Received Recognition for Excellence in Plastic Duplication Technology for contribution to improved product quality.

- Awarded Duplicator of the Year for outstanding performance in plastic replication.

- Recognized for achieving the highest plastic duplication precision rate in the team.

- Honored with the Master Duplicator award for exceptional skill and contribution to the field.

Certificates

- Certified Plastic Products Design Engineer (CPPDE)

- Certified Plastics Technician (CPT)

- Certified Molding Technician (CMT)

- Certified Extrusion Operator (CEO)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Duplicator

- Highlight your experience and skills in plastic duplication.

- Quantify your accomplishments whenever possible.

- Use action verbs to describe your responsibilities.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Plastic Duplicator Resume

- Operate and maintain a variety of plastic manufacturing equipment, including injection molding machines, blow molding machines, extruders, and thermoforming machines.

- Produce plastic parts and products to meet customer specifications.

- Inspect plastic parts and products for quality and accuracy.

- Troubleshoot and resolve production problems.

- Maintain a clean and safe work environment.

- Follow company policies and procedures.

- Communicate with customers and other employees effectively.

Frequently Asked Questions (FAQ’s) For Plastic Duplicator

What is a plastic duplicator?

A plastic duplicator is a person who creates copies of plastic parts and products using a variety of manufacturing methods.

What are the different types of plastic duplication methods?

Injection molding, blow molding, extrusion, and thermoforming are some common plastic duplication methods.

What are the different types of plastic materials used in duplication?

Polyethylene, polypropylene, and polyvinyl chloride are some common plastic materials used in duplication.

What are the key skills required for a plastic duplicator?

Injection molding, blow molding, extrusion, thermoforming, tool and die making, and plastic welding are some key skills required for a plastic duplicator.

What are the career opportunities for a plastic duplicator?

Plastic duplicators can work in a variety of industries, including automotive, aerospace, and medical.