Are you a seasoned Plastic Extrusion Operator seeking a new career path? Discover our professionally built Plastic Extrusion Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

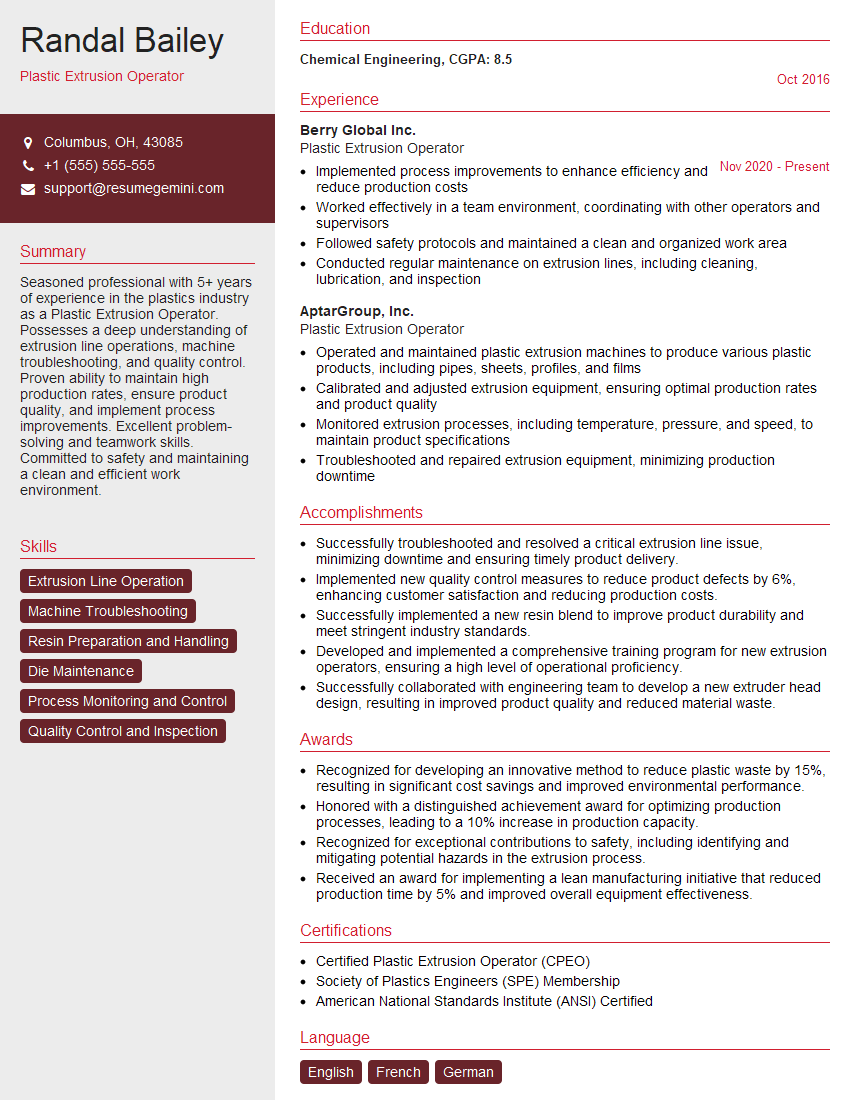

Randal Bailey

Plastic Extrusion Operator

Summary

Seasoned professional with 5+ years of experience in the plastics industry as a Plastic Extrusion Operator. Possesses a deep understanding of extrusion line operations, machine troubleshooting, and quality control. Proven ability to maintain high production rates, ensure product quality, and implement process improvements. Excellent problem-solving and teamwork skills. Committed to safety and maintaining a clean and efficient work environment.

Education

Chemical Engineering

October 2016

Skills

- Extrusion Line Operation

- Machine Troubleshooting

- Resin Preparation and Handling

- Die Maintenance

- Process Monitoring and Control

- Quality Control and Inspection

Work Experience

Plastic Extrusion Operator

- Implemented process improvements to enhance efficiency and reduce production costs

- Worked effectively in a team environment, coordinating with other operators and supervisors

- Followed safety protocols and maintained a clean and organized work area

- Conducted regular maintenance on extrusion lines, including cleaning, lubrication, and inspection

Plastic Extrusion Operator

- Operated and maintained plastic extrusion machines to produce various plastic products, including pipes, sheets, profiles, and films

- Calibrated and adjusted extrusion equipment, ensuring optimal production rates and product quality

- Monitored extrusion processes, including temperature, pressure, and speed, to maintain product specifications

- Troubleshooted and repaired extrusion equipment, minimizing production downtime

Accomplishments

- Successfully troubleshooted and resolved a critical extrusion line issue, minimizing downtime and ensuring timely product delivery.

- Implemented new quality control measures to reduce product defects by 6%, enhancing customer satisfaction and reducing production costs.

- Successfully implemented a new resin blend to improve product durability and meet stringent industry standards.

- Developed and implemented a comprehensive training program for new extrusion operators, ensuring a high level of operational proficiency.

- Successfully collaborated with engineering team to develop a new extruder head design, resulting in improved product quality and reduced material waste.

Awards

- Recognized for developing an innovative method to reduce plastic waste by 15%, resulting in significant cost savings and improved environmental performance.

- Honored with a distinguished achievement award for optimizing production processes, leading to a 10% increase in production capacity.

- Recognized for exceptional contributions to safety, including identifying and mitigating potential hazards in the extrusion process.

- Received an award for implementing a lean manufacturing initiative that reduced production time by 5% and improved overall equipment effectiveness.

Certificates

- Certified Plastic Extrusion Operator (CPEO)

- Society of Plastics Engineers (SPE) Membership

- American National Standards Institute (ANSI) Certified

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Extrusion Operator

- Highlight your experience in operating and maintaining plastic extrusion machines.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Demonstrate your knowledge of extrusion processes, including temperature, pressure, and speed control.

- Showcase your ability to troubleshoot and repair extrusion equipment, minimizing downtime.

Essential Experience Highlights for a Strong Plastic Extrusion Operator Resume

- Operated and maintained plastic extrusion machines to produce a variety of plastic products, including pipes, sheets, profiles, and films.

- Calibrated and adjusted extrusion equipment to ensure optimal production rates and product quality.

- Monitored extrusion processes, including temperature, pressure, and speed, to maintain product specifications.

- Troubleshooted and repaired extrusion equipment, minimizing production downtime.

- Implemented process improvements to enhance efficiency and reduce production costs.

- Worked effectively in a team environment, coordinating with other operators and supervisors.

- Followed safety protocols and maintained a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Plastic Extrusion Operator

What is the role of a Plastic Extrusion Operator?

A Plastic Extrusion Operator is responsible for operating and maintaining plastic extrusion machines to produce a variety of plastic products, such as pipes, sheets, profiles, and films. They calibrate and adjust extrusion equipment, monitor extrusion processes, troubleshoot and repair equipment, and implement process improvements to enhance efficiency and reduce production costs.

What skills are required to be a Plastic Extrusion Operator?

Key skills for a Plastic Extrusion Operator include extrusion line operation, machine troubleshooting, resin preparation and handling, die maintenance, process monitoring and control, quality control and inspection.

What is the work environment of a Plastic Extrusion Operator?

Plastic Extrusion Operators typically work in manufacturing facilities, operating extrusion machines in a production environment. They may work with other operators, supervisors, and engineers to ensure smooth production processes.

What are the career prospects for a Plastic Extrusion Operator?

With experience and additional training, Plastic Extrusion Operators can advance to roles such as Extrusion Supervisor, Production Manager, or Quality Control Manager. They may also specialize in a particular area of extrusion, such as pipe extrusion or film extrusion.

What safety precautions should a Plastic Extrusion Operator take?

Plastic Extrusion Operators should follow safety protocols and wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs. They should be aware of potential hazards, such as hot surfaces and moving machinery, and operate equipment safely to minimize risks.

What is the salary range for a Plastic Extrusion Operator?

The salary range for a Plastic Extrusion Operator can vary depending on experience, location, and company size. According to Salary.com, the average salary for a Plastic Extrusion Operator in the United States is around $50,000 per year.