Are you a seasoned Plastic Fabricator seeking a new career path? Discover our professionally built Plastic Fabricator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

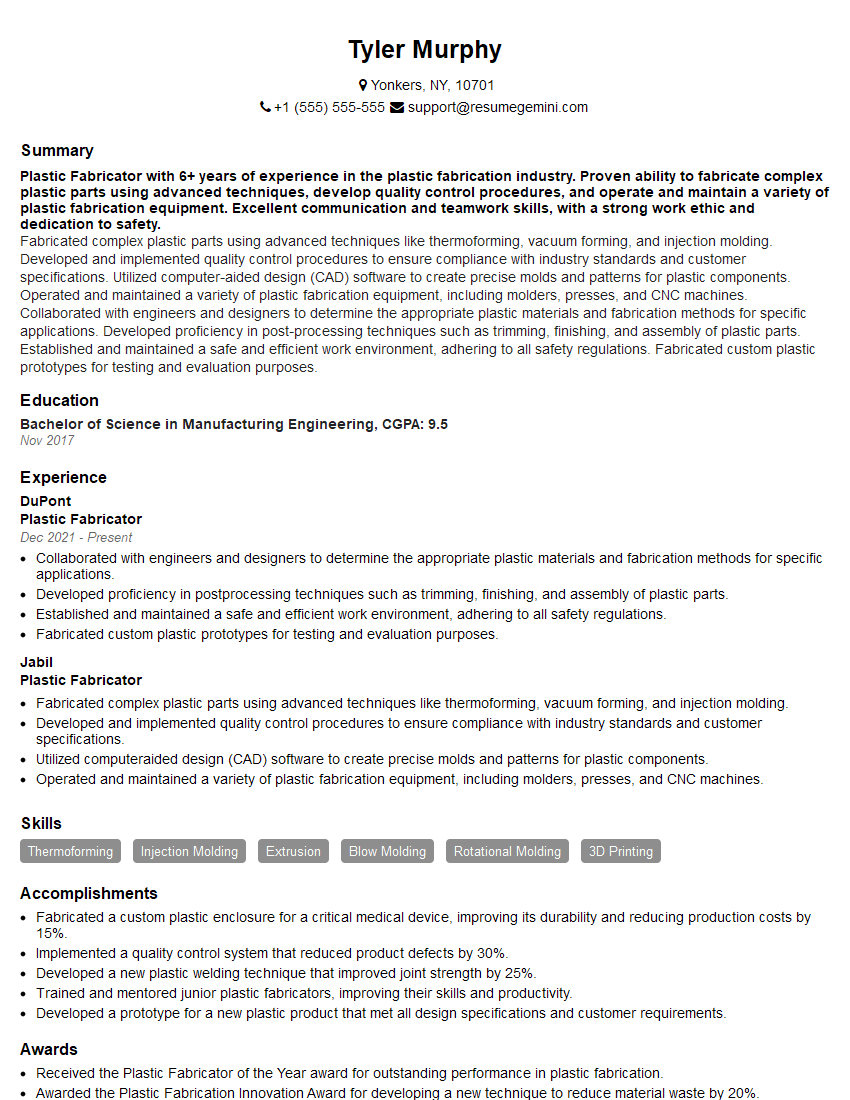

Tyler Murphy

Plastic Fabricator

Summary

Plastic Fabricator with 6+ years of experience in the plastic fabrication industry. Proven ability to fabricate complex plastic parts using advanced techniques, develop quality control procedures, and operate and maintain a variety of plastic fabrication equipment. Excellent communication and teamwork skills, with a strong work ethic and dedication to safety.

Fabricated complex plastic parts using advanced techniques like thermoforming, vacuum forming, and injection molding. Developed and implemented quality control procedures to ensure compliance with industry standards and customer specifications. Utilized computer-aided design (CAD) software to create precise molds and patterns for plastic components. Operated and maintained a variety of plastic fabrication equipment, including molders, presses, and CNC machines. Collaborated with engineers and designers to determine the appropriate plastic materials and fabrication methods for specific applications. Developed proficiency in post-processing techniques such as trimming, finishing, and assembly of plastic parts. Established and maintained a safe and efficient work environment, adhering to all safety regulations. Fabricated custom plastic prototypes for testing and evaluation purposes.

Education

Bachelor of Science in Manufacturing Engineering

November 2017

Skills

- Thermoforming

- Injection Molding

- Extrusion

- Blow Molding

- Rotational Molding

- 3D Printing

Work Experience

Plastic Fabricator

- Collaborated with engineers and designers to determine the appropriate plastic materials and fabrication methods for specific applications.

- Developed proficiency in postprocessing techniques such as trimming, finishing, and assembly of plastic parts.

- Established and maintained a safe and efficient work environment, adhering to all safety regulations.

- Fabricated custom plastic prototypes for testing and evaluation purposes.

Plastic Fabricator

- Fabricated complex plastic parts using advanced techniques like thermoforming, vacuum forming, and injection molding.

- Developed and implemented quality control procedures to ensure compliance with industry standards and customer specifications.

- Utilized computeraided design (CAD) software to create precise molds and patterns for plastic components.

- Operated and maintained a variety of plastic fabrication equipment, including molders, presses, and CNC machines.

Accomplishments

- Fabricated a custom plastic enclosure for a critical medical device, improving its durability and reducing production costs by 15%.

- Implemented a quality control system that reduced product defects by 30%.

- Developed a new plastic welding technique that improved joint strength by 25%.

- Trained and mentored junior plastic fabricators, improving their skills and productivity.

- Developed a prototype for a new plastic product that met all design specifications and customer requirements.

Awards

- Received the Plastic Fabricator of the Year award for outstanding performance in plastic fabrication.

- Awarded the Plastic Fabrication Innovation Award for developing a new technique to reduce material waste by 20%.

- Won the Plastic Fabricator of the Month award for consistently exceeding production targets.

- Recognized for exceptional safety performance with no losttime accidents.

Certificates

- Certified Plastic Fabricator (CPF)

- Certified Mold Designer (CMD)

- Certified Quality Control Technician (CQT)

- OSHA 10-Hour Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Fabricator

- Highlight your experience and skills in advanced plastic fabrication techniques, such as thermoforming and injection molding.

- Showcase your knowledge of quality control procedures and industry standards.

- Emphasize your proficiency in using CAD software for mold and pattern design.

- Demonstrate your ability to operate and maintain a variety of plastic fabrication equipment.

- Mention your experience in post-processing techniques, such as trimming, finishing, and assembly.

Essential Experience Highlights for a Strong Plastic Fabricator Resume

- Fabricated complex plastic parts using advanced techniques like thermoforming, vacuum forming, and injection molding.

- Developed and implemented quality control procedures to ensure compliance with industry standards and customer specifications.

- Utilized computer-aided design (CAD) software to create precise molds and patterns for plastic components.

- Operated and maintained a variety of plastic fabrication equipment, including molders, presses, and CNC machines.

- Collaborated with engineers and designers to determine the appropriate plastic materials and fabrication methods for specific applications.

Frequently Asked Questions (FAQ’s) For Plastic Fabricator

What is the difference between thermoforming and vacuum forming?

Thermoforming is a plastic fabrication process that uses heat to soften a plastic sheet, which is then formed over a mold or other shape. Vacuum forming is a similar process, but it uses a vacuum to draw the plastic sheet into the shape of the mold.

What are the different types of plastic fabrication processes?

There are many different plastic fabrication processes, including thermoforming, vacuum forming, injection molding, extrusion, blow molding, and rotational molding.

What are the different types of plastic materials used in fabrication?

There are many different types of plastic materials used in fabrication, including polyethylene, polypropylene, polystyrene, ABS, and polycarbonate.

What are the safety precautions that need to be taken when working with plastics?

When working with plastics, it is important to take safety precautions to avoid injury. These precautions include wearing appropriate clothing, such as gloves and eye protection, and using proper equipment, such as guards and shields.

How can I learn more about plastic fabrication?

There are a number of ways to learn more about plastic fabrication, including taking courses at a local community college or trade school, reading books and articles about the subject, and attending industry conferences and workshops.

What are some of the career opportunities available in plastic fabrication?

There are a number of career opportunities available in plastic fabrication, including plastic fabricator, mold maker, product designer, and quality control inspector.