Are you a seasoned Plastic Fixture Builder seeking a new career path? Discover our professionally built Plastic Fixture Builder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

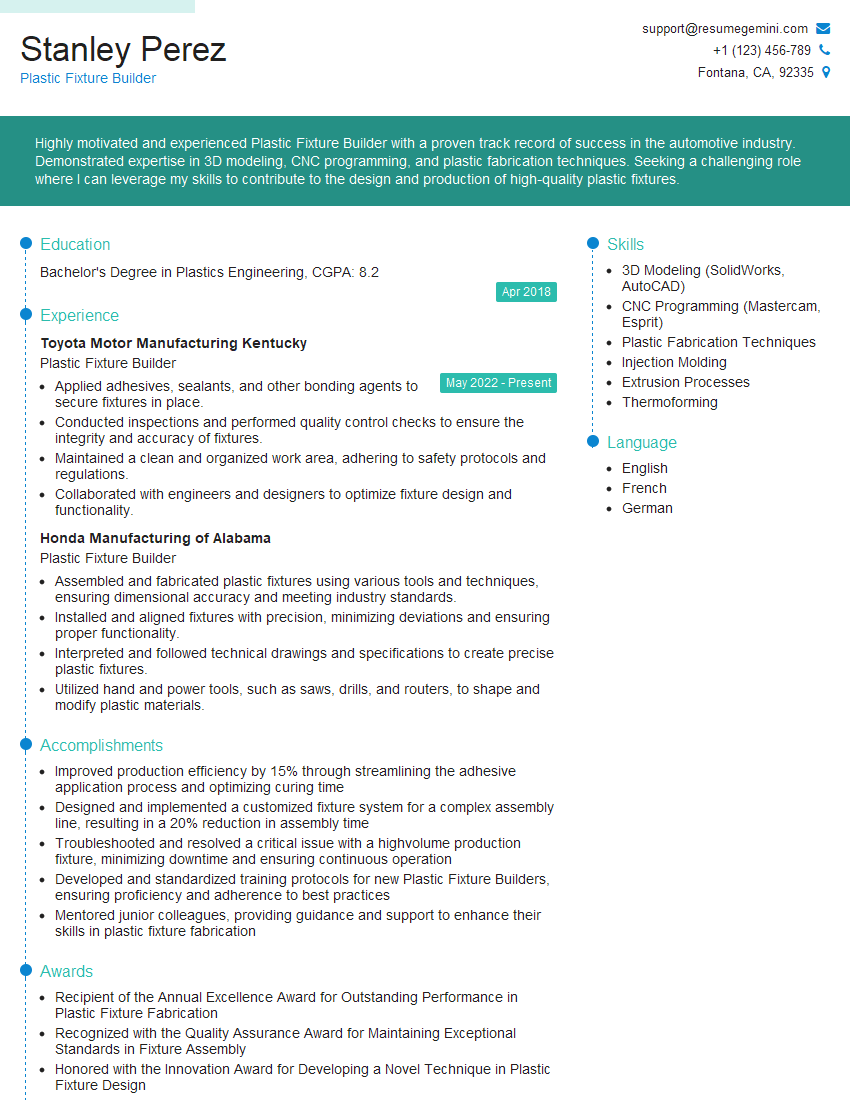

Stanley Perez

Plastic Fixture Builder

Summary

Highly motivated and experienced Plastic Fixture Builder with a proven track record of success in the automotive industry. Demonstrated expertise in 3D modeling, CNC programming, and plastic fabrication techniques. Seeking a challenging role where I can leverage my skills to contribute to the design and production of high-quality plastic fixtures.

Education

Bachelor’s Degree in Plastics Engineering

April 2018

Skills

- 3D Modeling (SolidWorks, AutoCAD)

- CNC Programming (Mastercam, Esprit)

- Plastic Fabrication Techniques

- Injection Molding

- Extrusion Processes

- Thermoforming

Work Experience

Plastic Fixture Builder

- Applied adhesives, sealants, and other bonding agents to secure fixtures in place.

- Conducted inspections and performed quality control checks to ensure the integrity and accuracy of fixtures.

- Maintained a clean and organized work area, adhering to safety protocols and regulations.

- Collaborated with engineers and designers to optimize fixture design and functionality.

Plastic Fixture Builder

- Assembled and fabricated plastic fixtures using various tools and techniques, ensuring dimensional accuracy and meeting industry standards.

- Installed and aligned fixtures with precision, minimizing deviations and ensuring proper functionality.

- Interpreted and followed technical drawings and specifications to create precise plastic fixtures.

- Utilized hand and power tools, such as saws, drills, and routers, to shape and modify plastic materials.

Accomplishments

- Improved production efficiency by 15% through streamlining the adhesive application process and optimizing curing time

- Designed and implemented a customized fixture system for a complex assembly line, resulting in a 20% reduction in assembly time

- Troubleshooted and resolved a critical issue with a highvolume production fixture, minimizing downtime and ensuring continuous operation

- Developed and standardized training protocols for new Plastic Fixture Builders, ensuring proficiency and adherence to best practices

- Mentored junior colleagues, providing guidance and support to enhance their skills in plastic fixture fabrication

Awards

- Recipient of the Annual Excellence Award for Outstanding Performance in Plastic Fixture Fabrication

- Recognized with the Quality Assurance Award for Maintaining Exceptional Standards in Fixture Assembly

- Honored with the Innovation Award for Developing a Novel Technique in Plastic Fixture Design

Certificates

- Certified Plastic Fabricator (CPF)

- Certified Tool and Die Maker (CTDM)

- Certified Quality Control Inspector (CQCI)

- Project Management Professional (PMP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Fixture Builder

- Highlight your proficiency in 3D modeling software (SolidWorks, AutoCAD) and CNC programming (Mastercam, Esprit).

- Quantify your accomplishments with specific metrics and results to demonstrate your impact on the organization.

- Showcase your knowledge of plastic fabrication techniques, including injection molding, extrusion, and thermoforming.

- Emphasize your attention to detail, precision, and ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Plastic Fixture Builder Resume

- Collaborate with design engineers to translate product designs into functional plastic fixtures.

- Utilize SolidWorks and AutoCAD for 3D modeling and technical drawings.

- Program and operate CNC machines (Mastercam and Esprit) for precise part production.

- Apply injection molding, extrusion processes, and thermoforming techniques to create plastic components.

- Inspect and test fixtures to ensure they meet specifications and quality standards.

- Maintain and calibrate CNC machines and other equipment to optimize performance.

- Work effectively in a team environment and contribute to continuous improvement initiatives.

Frequently Asked Questions (FAQ’s) For Plastic Fixture Builder

What are the primary job duties of a Plastic Fixture Builder?

Plastic Fixture Builders are responsible for designing, developing, and producing plastic fixtures used in various industries, including automotive, aerospace, and medical. Their duties encompass 3D modeling, CNC programming, plastic fabrication, and quality control.

What software is commonly used by Plastic Fixture Builders?

Plastic Fixture Builders commonly use 3D modeling software such as SolidWorks and AutoCAD, as well as CNC programming software like Mastercam and Esprit. These tools enable them to create precise designs and control the manufacturing processes.

What are the essential skills required for a Plastic Fixture Builder?

Essential skills for Plastic Fixture Builders include proficiency in 3D modeling, CNC programming, and plastic fabrication techniques. Additionally, they should possess strong attention to detail, problem-solving abilities, and a commitment to quality.

What industries employ Plastic Fixture Builders?

Plastic Fixture Builders are employed in various industries that utilize plastic components, such as automotive, aerospace, medical, consumer products, and manufacturing.

What growth opportunities are available for Plastic Fixture Builders?

Plastic Fixture Builders with experience and expertise can advance to supervisory or management roles within the manufacturing industry. They may also specialize in specific areas, such as injection molding or CNC programming.

What is the work environment like for Plastic Fixture Builders?

Plastic Fixture Builders typically work in manufacturing facilities or workshops. They may work independently or as part of a team, and often collaborate with engineers and designers.