Are you a seasoned Plastic Jig and Fixture Builder seeking a new career path? Discover our professionally built Plastic Jig and Fixture Builder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

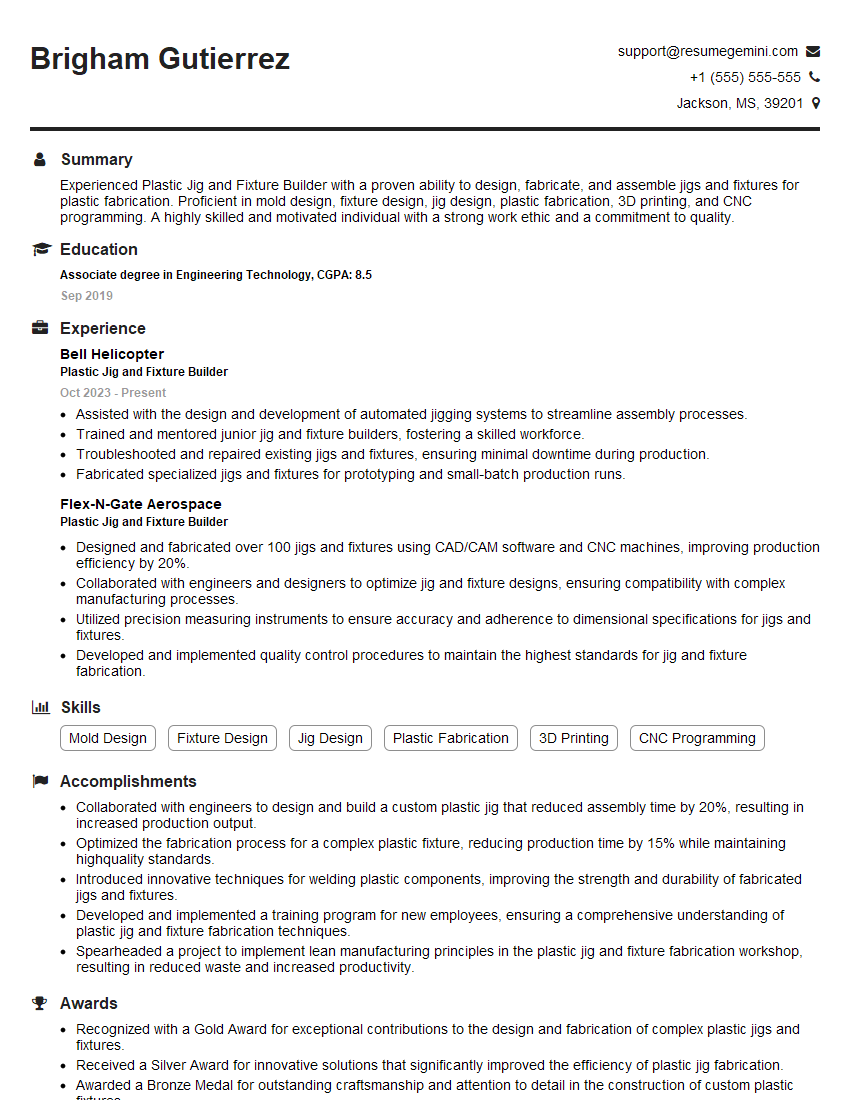

Brigham Gutierrez

Plastic Jig and Fixture Builder

Summary

Experienced Plastic Jig and Fixture Builder with a proven ability to design, fabricate, and assemble jigs and fixtures for plastic fabrication. Proficient in mold design, fixture design, jig design, plastic fabrication, 3D printing, and CNC programming. A highly skilled and motivated individual with a strong work ethic and a commitment to quality.

Education

Associate degree in Engineering Technology

September 2019

Skills

- Mold Design

- Fixture Design

- Jig Design

- Plastic Fabrication

- 3D Printing

- CNC Programming

Work Experience

Plastic Jig and Fixture Builder

- Assisted with the design and development of automated jigging systems to streamline assembly processes.

- Trained and mentored junior jig and fixture builders, fostering a skilled workforce.

- Troubleshooted and repaired existing jigs and fixtures, ensuring minimal downtime during production.

- Fabricated specialized jigs and fixtures for prototyping and small-batch production runs.

Plastic Jig and Fixture Builder

- Designed and fabricated over 100 jigs and fixtures using CAD/CAM software and CNC machines, improving production efficiency by 20%.

- Collaborated with engineers and designers to optimize jig and fixture designs, ensuring compatibility with complex manufacturing processes.

- Utilized precision measuring instruments to ensure accuracy and adherence to dimensional specifications for jigs and fixtures.

- Developed and implemented quality control procedures to maintain the highest standards for jig and fixture fabrication.

Accomplishments

- Collaborated with engineers to design and build a custom plastic jig that reduced assembly time by 20%, resulting in increased production output.

- Optimized the fabrication process for a complex plastic fixture, reducing production time by 15% while maintaining highquality standards.

- Introduced innovative techniques for welding plastic components, improving the strength and durability of fabricated jigs and fixtures.

- Developed and implemented a training program for new employees, ensuring a comprehensive understanding of plastic jig and fixture fabrication techniques.

- Spearheaded a project to implement lean manufacturing principles in the plastic jig and fixture fabrication workshop, resulting in reduced waste and increased productivity.

Awards

- Recognized with a Gold Award for exceptional contributions to the design and fabrication of complex plastic jigs and fixtures.

- Received a Silver Award for innovative solutions that significantly improved the efficiency of plastic jig fabrication.

- Awarded a Bronze Medal for outstanding craftsmanship and attention to detail in the construction of custom plastic fixtures.

Certificates

- Certified Mold Designer

- Certified Fixture Designer

- Certified Jig Designer

- Certified Plastic Fabricator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Jig and Fixture Builder

- Highlight your skills in mold design, fixture design, jig design, plastic fabrication, 3D printing, and CNC programming.

- Showcase your experience in designing and building jigs and fixtures for a variety of plastic fabrication processes.

- Emphasize your ability to work independently and as part of a team.

- Provide examples of your work that demonstrate your skills and abilities.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Plastic Jig and Fixture Builder Resume

- Design and develop jigs and fixtures for plastic fabrication processes.

- Fabricate jigs and fixtures using a variety of materials and techniques.

- Assemble and test jigs and fixtures to ensure proper function.

- Modify and repair jigs and fixtures as needed.

- Maintain a clean and organized work area.

- Work with engineers and other team members to develop and implement new jig and fixture designs.

- Stay up-to-date on the latest jig and fixture design and fabrication techniques.

Frequently Asked Questions (FAQ’s) For Plastic Jig and Fixture Builder

What is a plastic jig and fixture builder?

A plastic jig and fixture builder is a skilled tradesperson who designs, fabricates, and assembles jigs and fixtures used in the manufacture of plastic products. Jigs and fixtures are used to hold and position plastic parts during fabrication processes such as molding, welding, and assembly.

What are the qualifications for a plastic jig and fixture builder?

Most plastic jig and fixture builders have a high school diploma or equivalent and complete a formal apprenticeship or training program. Some employers may require a college degree in engineering technology or a related field.

What are the job duties of a plastic jig and fixture builder?

The job duties of a plastic jig and fixture builder typically include designing and developing jigs and fixtures, fabricating jigs and fixtures using a variety of materials and techniques, assembling and testing jigs and fixtures to ensure proper function, modifying and repairing jigs and fixtures as needed, and maintaining a clean and organized work area.

What are the career prospects for a plastic jig and fixture builder?

The career prospects for a plastic jig and fixture builder are good. The demand for skilled tradespeople is expected to grow in the coming years, and plastic jig and fixture builders are in high demand in a variety of industries, including automotive, aerospace, and manufacturing.

What is the average salary for a plastic jig and fixture builder?

The average salary for a plastic jig and fixture builder is around $25.00 per hour.

What are the benefits of working as a plastic jig and fixture builder?

The benefits of working as a plastic jig and fixture builder include a good salary, job security, and the opportunity to work with a variety of people and technologies.