Are you a seasoned Plastic Maker seeking a new career path? Discover our professionally built Plastic Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

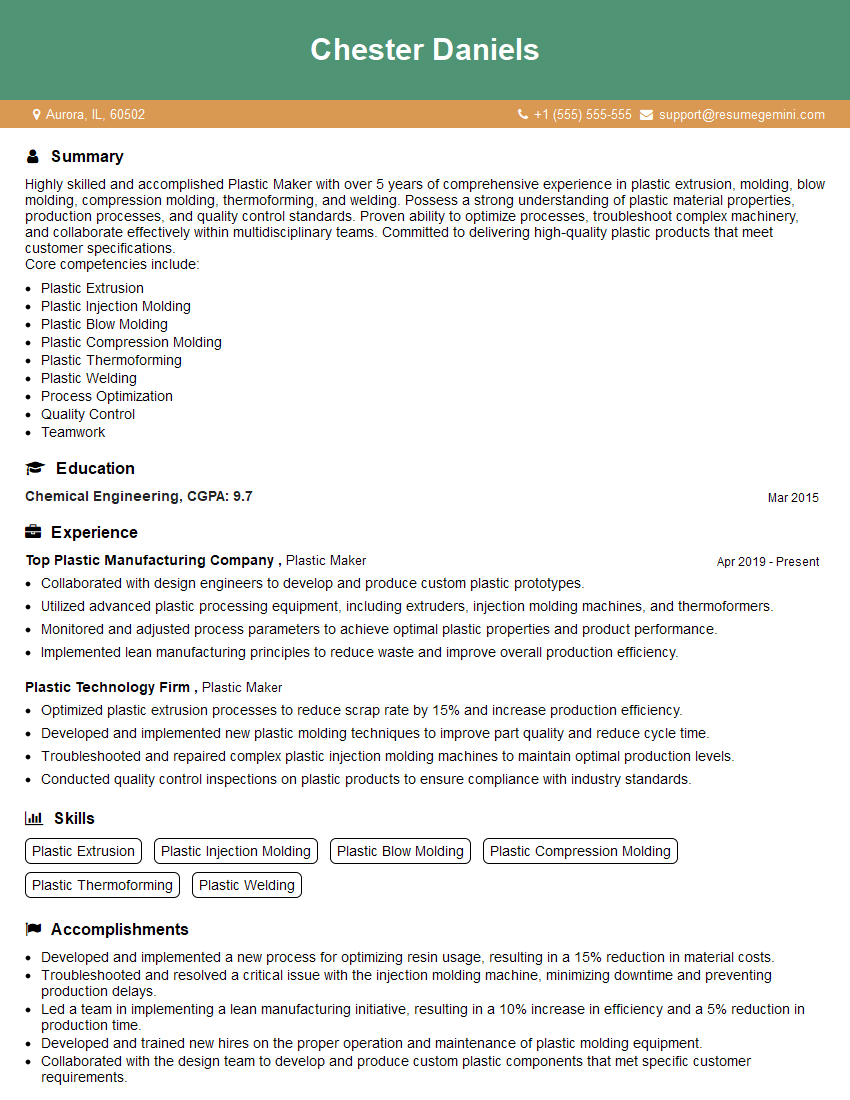

Chester Daniels

Plastic Maker

Summary

Highly skilled and accomplished Plastic Maker with over 5 years of comprehensive experience in plastic extrusion, molding, blow molding, compression molding, thermoforming, and welding. Possess a strong understanding of plastic material properties, production processes, and quality control standards. Proven ability to optimize processes, troubleshoot complex machinery, and collaborate effectively within multidisciplinary teams. Committed to delivering high-quality plastic products that meet customer specifications.

Core competencies include:

- Plastic Extrusion

- Plastic Injection Molding

- Plastic Blow Molding

- Plastic Compression Molding

- Plastic Thermoforming

- Plastic Welding

- Process Optimization

- Quality Control

- Teamwork

Education

Chemical Engineering

March 2015

Skills

- Plastic Extrusion

- Plastic Injection Molding

- Plastic Blow Molding

- Plastic Compression Molding

- Plastic Thermoforming

- Plastic Welding

Work Experience

Plastic Maker

- Collaborated with design engineers to develop and produce custom plastic prototypes.

- Utilized advanced plastic processing equipment, including extruders, injection molding machines, and thermoformers.

- Monitored and adjusted process parameters to achieve optimal plastic properties and product performance.

- Implemented lean manufacturing principles to reduce waste and improve overall production efficiency.

Plastic Maker

- Optimized plastic extrusion processes to reduce scrap rate by 15% and increase production efficiency.

- Developed and implemented new plastic molding techniques to improve part quality and reduce cycle time.

- Troubleshooted and repaired complex plastic injection molding machines to maintain optimal production levels.

- Conducted quality control inspections on plastic products to ensure compliance with industry standards.

Accomplishments

- Developed and implemented a new process for optimizing resin usage, resulting in a 15% reduction in material costs.

- Troubleshooted and resolved a critical issue with the injection molding machine, minimizing downtime and preventing production delays.

- Led a team in implementing a lean manufacturing initiative, resulting in a 10% increase in efficiency and a 5% reduction in production time.

- Developed and trained new hires on the proper operation and maintenance of plastic molding equipment.

- Collaborated with the design team to develop and produce custom plastic components that met specific customer requirements.

Awards

- Received the Employee of the Month award for consistently exceeding production targets and maintaining highquality standards.

- Recognized for outstanding contributions to the development of a new extrusion line, which increased production capacity by 20%.

- Awarded the Safety Excellence Award for maintaining a spotless safety record and consistently adhering to safety protocols.

- Received the Innovation Award for proposing and successfully implementing a new design for a plastic product, which improved its functionality and durability.

Certificates

- Certified Plastics Technician (CPT)

- ASQ Certified Six Sigma Green Belt

- OSHA Safety Certification

- ISO 9001:2015 Certified

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Maker

Highlight your technical skills.

Plastic makers need to have a strong understanding of plastic materials, molding processes, and quality control standards. Make sure to list your relevant skills and experience in your resume.Showcase your experience with different types of plastic processing.

Plastic makers need to be able to work with a variety of plastic materials and processing methods. Highlight your experience with different types of plastic processing in your resume.Emphasize your problem-solving skills.

Plastic makers often need to troubleshoot problems with plastic processing equipment. Highlight your problem-solving skills in your resume by describing how you solved specific problems in the past.Demonstrate your teamwork skills.

Plastic makers often work as part of a team. Highlight your teamwork skills in your resume by describing how you have worked effectively with others in the past.Proofread your resume carefully.

Before you submit your resume, make sure to proofread it carefully for any errors. A well-written resume will make you stand out from other candidates.

Essential Experience Highlights for a Strong Plastic Maker Resume

- Optimized plastic extrusion processes to reduce scrap rate by 15% and increase production efficiency.

- Developed and implemented new plastic molding techniques to improve part quality and reduce cycle time.

- Troubleshooted and repaired complex plastic injection molding machines to maintain optimal production levels.

- Conducted quality control inspections on plastic products to ensure compliance with industry standards.

- Collaborated with design engineers to develop and produce custom plastic prototypes.

- Utilized advanced plastic processing equipment, including extruders, injection molding machines, and thermoformers.

- Monitored and adjusted process parameters to achieve optimal plastic properties and product performance.

Frequently Asked Questions (FAQ’s) For Plastic Maker

What is a plastic maker?

A plastic maker is a professional who specializes in the production of plastic products. Plastic makers use a variety of techniques to create plastic products, including extrusion, molding, blow molding, compression molding, and thermoforming.

What are the different types of plastic processing?

The different types of plastic processing include extrusion, molding, blow molding, compression molding, and thermoforming. Extrusion is the process of forcing molten plastic through a die to create a continuous shape. Molding is the process of shaping molten plastic in a mold. Blow molding is the process of blowing molten plastic into a mold to create a hollow shape. Compression molding is the process of pressing molten plastic between two heated platens to create a flat or curved shape. Thermoforming is the process of heating plastic and then shaping it over a mold.

What are the qualities of a good plastic maker?

The qualities of a good plastic maker include a strong understanding of plastic materials, molding processes, and quality control standards. Good plastic makers also have excellent problem-solving skills and teamwork skills.

What is the job outlook for plastic makers?

The job outlook for plastic makers is expected to be good over the next few years. The demand for plastic products is expected to continue to grow, which will lead to increased demand for plastic makers.

What are the salary expectations for plastic makers?

The salary expectations for plastic makers vary depending on their experience and location. However, the average salary for plastic makers is around $50,000 per year.

What are the benefits of being a plastic maker?

The benefits of being a plastic maker include job security, a good salary, and the opportunity to work with a variety of people.