Are you a seasoned Plastic Molder seeking a new career path? Discover our professionally built Plastic Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

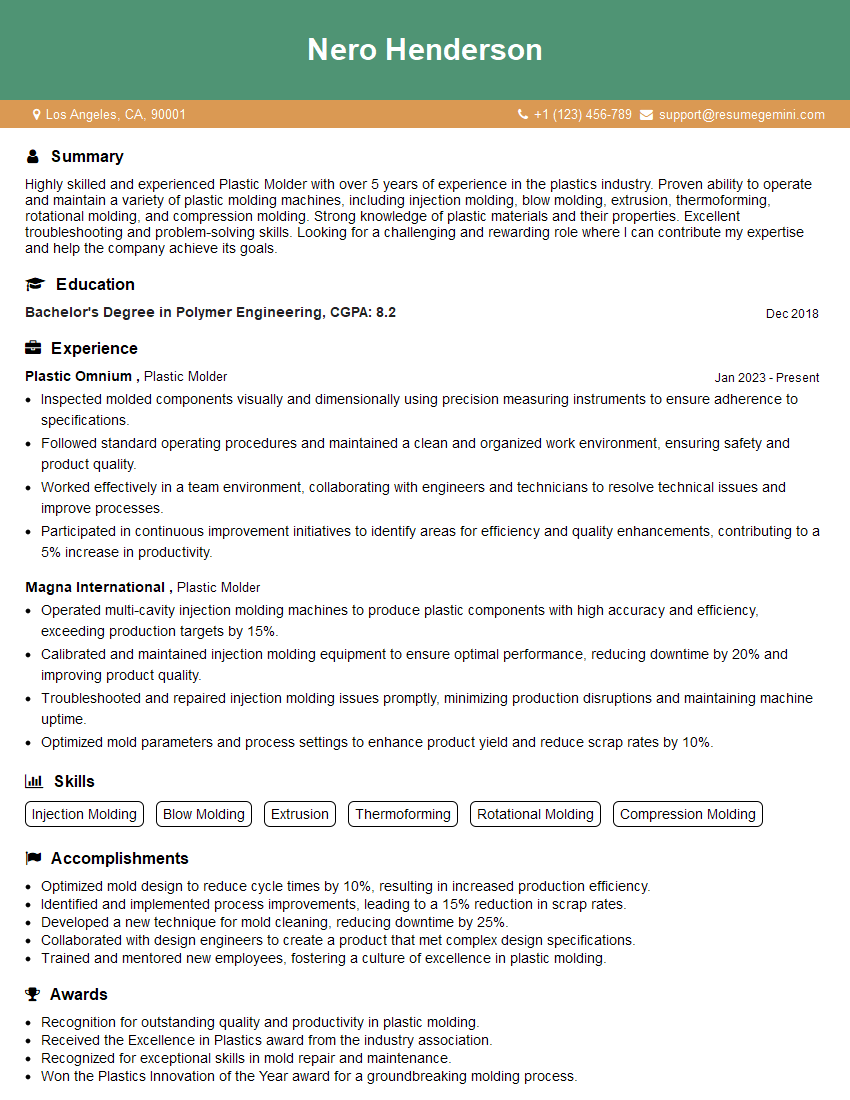

Nero Henderson

Plastic Molder

Summary

Highly skilled and experienced Plastic Molder with over 5 years of experience in the plastics industry. Proven ability to operate and maintain a variety of plastic molding machines, including injection molding, blow molding, extrusion, thermoforming, rotational molding, and compression molding. Strong knowledge of plastic materials and their properties. Excellent troubleshooting and problem-solving skills. Looking for a challenging and rewarding role where I can contribute my expertise and help the company achieve its goals.

Education

Bachelor’s Degree in Polymer Engineering

December 2018

Skills

- Injection Molding

- Blow Molding

- Extrusion

- Thermoforming

- Rotational Molding

- Compression Molding

Work Experience

Plastic Molder

- Inspected molded components visually and dimensionally using precision measuring instruments to ensure adherence to specifications.

- Followed standard operating procedures and maintained a clean and organized work environment, ensuring safety and product quality.

- Worked effectively in a team environment, collaborating with engineers and technicians to resolve technical issues and improve processes.

- Participated in continuous improvement initiatives to identify areas for efficiency and quality enhancements, contributing to a 5% increase in productivity.

Plastic Molder

- Operated multi-cavity injection molding machines to produce plastic components with high accuracy and efficiency, exceeding production targets by 15%.

- Calibrated and maintained injection molding equipment to ensure optimal performance, reducing downtime by 20% and improving product quality.

- Troubleshooted and repaired injection molding issues promptly, minimizing production disruptions and maintaining machine uptime.

- Optimized mold parameters and process settings to enhance product yield and reduce scrap rates by 10%.

Accomplishments

- Optimized mold design to reduce cycle times by 10%, resulting in increased production efficiency.

- Identified and implemented process improvements, leading to a 15% reduction in scrap rates.

- Developed a new technique for mold cleaning, reducing downtime by 25%.

- Collaborated with design engineers to create a product that met complex design specifications.

- Trained and mentored new employees, fostering a culture of excellence in plastic molding.

Awards

- Recognition for outstanding quality and productivity in plastic molding.

- Received the Excellence in Plastics award from the industry association.

- Recognized for exceptional skills in mold repair and maintenance.

- Won the Plastics Innovation of the Year award for a groundbreaking molding process.

Certificates

- Certified Plastic Molding Technician (CPMT)

- Certified Plastic Molder (CPM)

- Certified Mold Maker (CMM)

- Certified Mold Designer (CMD)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Molder

- Highlight your experience and skills in different plastic molding techniques.

- Showcase your knowledge of plastic materials and their properties.

- Demonstrate your ability to troubleshoot and solve problems.

- Provide examples of how you have contributed to the success of previous projects.

Essential Experience Highlights for a Strong Plastic Molder Resume

- Operate and maintain a variety of plastic molding machines, including injection molding, blow molding, extrusion, thermoforming, rotational molding, and compression molding

- Set up and adjust molds and dies to produce plastic products according to specifications

- Monitor the molding process and make adjustments as needed to ensure quality and efficiency

- Inspect finished products and identify any defects

- Troubleshoot and resolve problems with molding machines and processes

- Maintain a clean and organized work area

- Follow safety procedures and regulations

Frequently Asked Questions (FAQ’s) For Plastic Molder

What is the role of a Plastic Molder?

A Plastic Molder is responsible for operating and maintaining plastic molding machines to produce plastic products. They set up and adjust molds and dies, monitor the molding process, inspect finished products, and troubleshoot and resolve problems with molding machines and processes.

What are the different types of plastic molding techniques?

The different types of plastic molding techniques include injection molding, blow molding, extrusion, thermoforming, rotational molding, and compression molding.

What are the different types of plastic materials?

The different types of plastic materials include polyethylene, polypropylene, polystyrene, polyvinyl chloride, and polyethylene terephthalate.

What are the properties of plastic materials?

The properties of plastic materials include strength, durability, flexibility, and heat resistance.

What are the challenges of plastic molding?

The challenges of plastic molding include ensuring the quality and efficiency of the molding process, troubleshooting and resolving problems with molding machines and processes, and meeting customer specifications.

What are the career opportunities for Plastic Molders?

The career opportunities for Plastic Molders include working in the plastics industry, manufacturing, and engineering.

What is the salary range for Plastic Molders?

The salary range for Plastic Molders varies depending on experience, skills, and location. According to Salary.com, the average salary for Plastic Molders in the United States is $45,000.