Are you a seasoned Plastic Numerical Tool and Process Control Programmer seeking a new career path? Discover our professionally built Plastic Numerical Tool and Process Control Programmer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

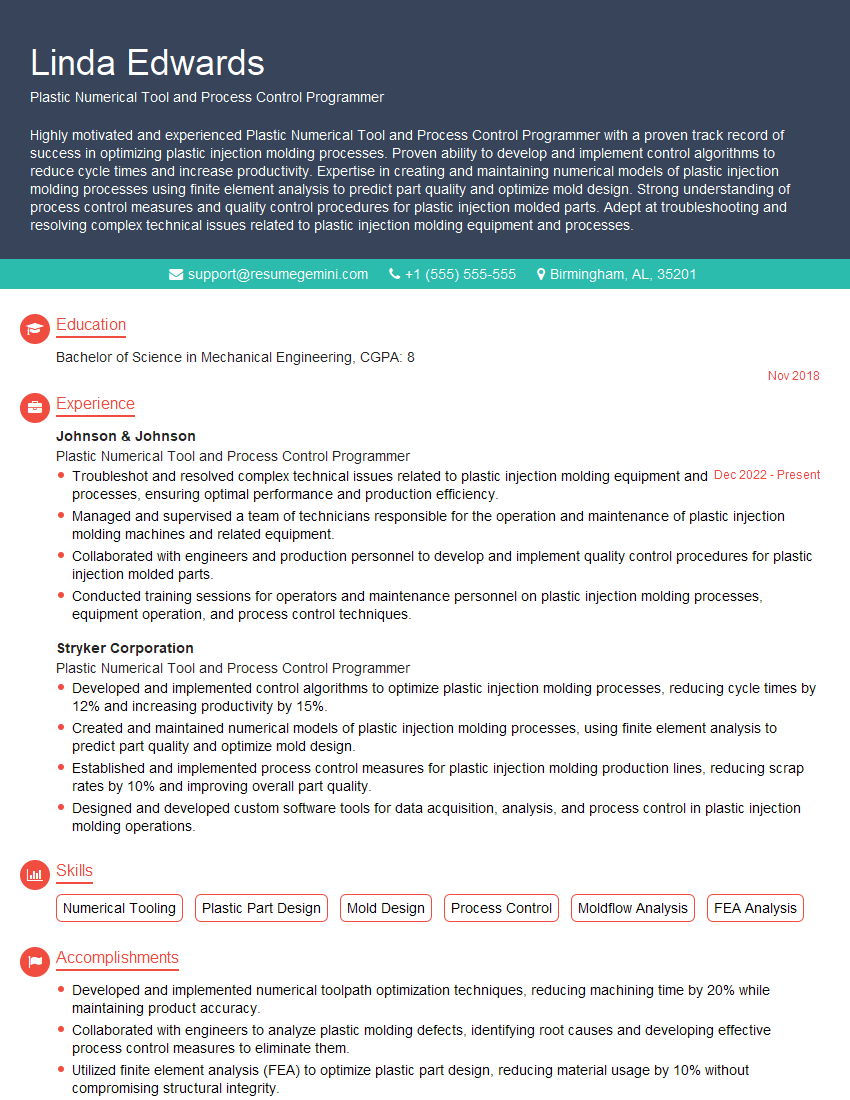

Linda Edwards

Plastic Numerical Tool and Process Control Programmer

Summary

Highly motivated and experienced Plastic Numerical Tool and Process Control Programmer with a proven track record of success in optimizing plastic injection molding processes. Proven ability to develop and implement control algorithms to reduce cycle times and increase productivity. Expertise in creating and maintaining numerical models of plastic injection molding processes using finite element analysis to predict part quality and optimize mold design. Strong understanding of process control measures and quality control procedures for plastic injection molded parts. Adept at troubleshooting and resolving complex technical issues related to plastic injection molding equipment and processes.

Education

Bachelor of Science in Mechanical Engineering

November 2018

Skills

- Numerical Tooling

- Plastic Part Design

- Mold Design

- Process Control

- Moldflow Analysis

- FEA Analysis

Work Experience

Plastic Numerical Tool and Process Control Programmer

- Troubleshot and resolved complex technical issues related to plastic injection molding equipment and processes, ensuring optimal performance and production efficiency.

- Managed and supervised a team of technicians responsible for the operation and maintenance of plastic injection molding machines and related equipment.

- Collaborated with engineers and production personnel to develop and implement quality control procedures for plastic injection molded parts.

- Conducted training sessions for operators and maintenance personnel on plastic injection molding processes, equipment operation, and process control techniques.

Plastic Numerical Tool and Process Control Programmer

- Developed and implemented control algorithms to optimize plastic injection molding processes, reducing cycle times by 12% and increasing productivity by 15%.

- Created and maintained numerical models of plastic injection molding processes, using finite element analysis to predict part quality and optimize mold design.

- Established and implemented process control measures for plastic injection molding production lines, reducing scrap rates by 10% and improving overall part quality.

- Designed and developed custom software tools for data acquisition, analysis, and process control in plastic injection molding operations.

Accomplishments

- Developed and implemented numerical toolpath optimization techniques, reducing machining time by 20% while maintaining product accuracy.

- Collaborated with engineers to analyze plastic molding defects, identifying root causes and developing effective process control measures to eliminate them.

- Utilized finite element analysis (FEA) to optimize plastic part design, reducing material usage by 10% without compromising structural integrity.

- Established and maintained quality control procedures for plastic molding operations, ensuring compliance with industry standards and customer specifications.

- Successfully integrated advanced process monitoring sensors into plastic molding machines, enabling realtime data collection and preventive maintenance.

Awards

- Received industry recognition for developing innovative process control algorithms that improved production efficiency by 15%.

- Recognized by management for exceptional contributions to the implementation of a new plastic molding simulation software, resulting in reduced product defects and increased quality.

- Awarded a patent for a novel plastic molding process that significantly improved product durability and reduced manufacturing costs.

- Honored by the company for outstanding performance in developing and deploying a comprehensive plastic molding process control system.

Certificates

- Certified Mold Designer (CMD)

- Certified Plastic Part Designer (CPPD)

- Certified Process Control Technician (CPCT)

- Certified Quality Control Inspector (CQCI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Numerical Tool and Process Control Programmer

- Highlight your experience in developing and implementing control algorithms to optimize plastic injection molding processes.

- Showcase your expertise in creating and maintaining numerical models of plastic injection molding processes using finite element analysis.

- Quantify your accomplishments in reducing cycle times, increasing productivity, and improving part quality.

- Emphasize your ability to troubleshoot and resolve complex technical issues related to plastic injection molding equipment and processes.

- Demonstrate your knowledge of process control measures and quality control procedures for plastic injection molded parts.

Essential Experience Highlights for a Strong Plastic Numerical Tool and Process Control Programmer Resume

- Develop and implement control algorithms to optimize plastic injection molding processes, reducing cycle times and increasing productivity.

- Create and maintain numerical models of plastic injection molding processes, using finite element analysis to predict part quality and optimize mold design.

- Establish and implement process control measures for plastic injection molding production lines, reducing scrap rates and improving overall part quality.

- Design and develop custom software tools for data acquisition, analysis, and process control in plastic injection molding operations.

- Troubleshoot and resolve complex technical issues related to plastic injection molding equipment and processes, ensuring optimal performance and production efficiency.

- Manage and supervise a team of technicians responsible for the operation and maintenance of plastic injection molding machines and related equipment.

- Collaborate with engineers and production personnel to develop and implement quality control procedures for plastic injection molded parts.

Frequently Asked Questions (FAQ’s) For Plastic Numerical Tool and Process Control Programmer

What are the key skills required to be a successful Plastic Numerical Tool and Process Control Programmer?

Key skills include numerical tooling, plastic part design, mold design, process control, Moldflow analysis, FEA analysis, and a strong understanding of plastic injection molding processes.

What are the career prospects for Plastic Numerical Tool and Process Control Programmers?

Plastic Numerical Tool and Process Control Programmers are in high demand in the manufacturing industry, particularly in the automotive, medical, and consumer products sectors.

What is the typical salary range for Plastic Numerical Tool and Process Control Programmers?

The salary range for Plastic Numerical Tool and Process Control Programmers can vary depending on experience, skills, and location, but typically ranges from $70,000 to $120,000 per year.

What are the educational requirements to become a Plastic Numerical Tool and Process Control Programmer?

Most Plastic Numerical Tool and Process Control Programmers have a bachelor’s degree in mechanical engineering, plastics engineering, or a related field.

What are some of the challenges faced by Plastic Numerical Tool and Process Control Programmers?

Some of the challenges faced by Plastic Numerical Tool and Process Control Programmers include optimizing complex plastic injection molding processes, troubleshooting technical issues, and ensuring the quality of plastic molded parts.

What are some of the latest trends in plastic numerical tooling and process control?

Some of the latest trends include the use of artificial intelligence and machine learning to optimize plastic injection molding processes, the development of new materials and technologies for plastic molding, and the increasing use of simulation and modeling to predict part quality and optimize mold design.

What are the key qualities of a successful Plastic Numerical Tool and Process Control Programmer?

Key qualities include a strong analytical mindset, problem-solving skills, attention to detail, and a passion for plastic injection molding technology.

What are the career advancement opportunities for Plastic Numerical Tool and Process Control Programmers?

With experience and additional training, Plastic Numerical Tool and Process Control Programmers can advance to roles such as Process Engineer, Manufacturing Engineer, or Quality Manager.