Are you a seasoned Plastic Parts Designer seeking a new career path? Discover our professionally built Plastic Parts Designer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

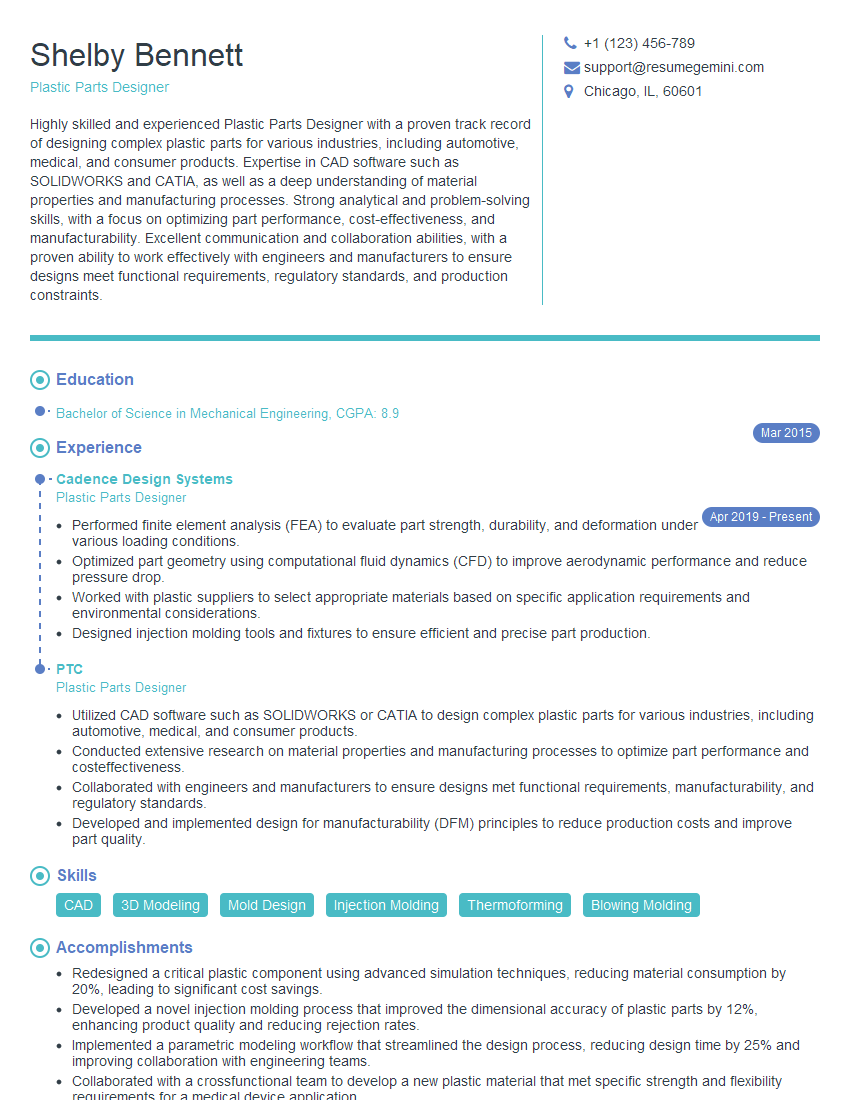

Shelby Bennett

Plastic Parts Designer

Summary

Highly skilled and experienced Plastic Parts Designer with a proven track record of designing complex plastic parts for various industries, including automotive, medical, and consumer products. Expertise in CAD software such as SOLIDWORKS and CATIA, as well as a deep understanding of material properties and manufacturing processes. Strong analytical and problem-solving skills, with a focus on optimizing part performance, cost-effectiveness, and manufacturability. Excellent communication and collaboration abilities, with a proven ability to work effectively with engineers and manufacturers to ensure designs meet functional requirements, regulatory standards, and production constraints.

Education

Bachelor of Science in Mechanical Engineering

March 2015

Skills

- CAD

- 3D Modeling

- Mold Design

- Injection Molding

- Thermoforming

- Blowing Molding

Work Experience

Plastic Parts Designer

- Performed finite element analysis (FEA) to evaluate part strength, durability, and deformation under various loading conditions.

- Optimized part geometry using computational fluid dynamics (CFD) to improve aerodynamic performance and reduce pressure drop.

- Worked with plastic suppliers to select appropriate materials based on specific application requirements and environmental considerations.

- Designed injection molding tools and fixtures to ensure efficient and precise part production.

Plastic Parts Designer

- Utilized CAD software such as SOLIDWORKS or CATIA to design complex plastic parts for various industries, including automotive, medical, and consumer products.

- Conducted extensive research on material properties and manufacturing processes to optimize part performance and costeffectiveness.

- Collaborated with engineers and manufacturers to ensure designs met functional requirements, manufacturability, and regulatory standards.

- Developed and implemented design for manufacturability (DFM) principles to reduce production costs and improve part quality.

Accomplishments

- Redesigned a critical plastic component using advanced simulation techniques, reducing material consumption by 20%, leading to significant cost savings.

- Developed a novel injection molding process that improved the dimensional accuracy of plastic parts by 12%, enhancing product quality and reducing rejection rates.

- Implemented a parametric modeling workflow that streamlined the design process, reducing design time by 25% and improving collaboration with engineering teams.

- Collaborated with a crossfunctional team to develop a new plastic material that met specific strength and flexibility requirements for a medical device application.

- Optimized the design of a plastic packaging container, reducing material waste by 18% while maintaining the required product protection.

Awards

- Received the Plastic Design Excellence Award from the American Society of Plastics Engineers (ASPE) for innovative design of a highperformance automotive part, reducing weight by 15% and improving fuel efficiency by 3%.

- Recognized with the Industry Leader Award by the Plastics Industry Association (PIA) for significant contributions to the advancement of plastic part design and manufacturing.

- Awarded the Best Design Concept Award in the Plastic Parts Design Competition organized by the Society of Automotive Engineers (SAE) for a revolutionary design of a lightweight and durable aircraft component.

- Received industry recognition for developing a patented plastic part design that revolutionized the manufacturing process for a specific product.

Certificates

- Certified Mold Designer (CMD)

- Certified Injection Molding Technician (CIMT)

- Certified Thermoforming Specialist (CTS)

- Certified Blowing Molding Technician (CBMT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Parts Designer

- Highlight your proficiency in CAD software, especially SOLIDWORKS or CATIA.

- Showcase your understanding of material properties and manufacturing processes relevant to plastic part design.

- Emphasize your ability to optimize designs for both performance and cost-effectiveness.

- Provide examples of your work where you have successfully implemented DFM principles or conducted FEA/CFD analysis.

Essential Experience Highlights for a Strong Plastic Parts Designer Resume

- Design complex plastic parts using CAD software such as SOLIDWORKS or CATIA.

- Conduct extensive research on material properties and manufacturing processes to optimize part performance and cost-effectiveness.

- Collaborate with engineers and manufacturers to ensure designs meet functional requirements, manufacturability, and regulatory standards.

- Develop and implement design for manufacturability (DFM) principles to reduce production costs and improve part quality.

- Perform finite element analysis (FEA) to evaluate part strength, durability, and deformation under various loading conditions.

- Optimize part geometry using computational fluid dynamics (CFD) to improve aerodynamic performance and reduce pressure drop.

Frequently Asked Questions (FAQ’s) For Plastic Parts Designer

What are the key skills required to be a successful Plastic Parts Designer?

The key skills required for a successful Plastic Parts Designer include proficiency in CAD software, knowledge of material properties and manufacturing processes, analytical and problem-solving abilities, and strong communication and collaboration skills.

What are the different industries that a Plastic Parts Designer can work in?

Plastic Parts Designers can work in various industries, including automotive, medical, consumer products, aerospace, and electronics.

What is the job outlook for Plastic Parts Designers?

The job outlook for Plastic Parts Designers is expected to be positive in the coming years, as there is a growing demand for plastic products in various industries.

What are the career advancement opportunities for Plastic Parts Designers?

Plastic Parts Designers can advance their careers by becoming Senior Plastic Parts Designers, Project Managers, or Design Engineers.

What are the educational requirements to become a Plastic Parts Designer?

Most Plastic Parts Designers have a Bachelor’s degree in Mechanical Engineering or a related field.

What are the professional organizations that Plastic Parts Designers can join?

Plastic Parts Designers can join professional organizations such as the Society of Plastics Engineers (SPE) and the American Society of Mechanical Engineers (ASME).