Are you a seasoned Plastic Patternmaker seeking a new career path? Discover our professionally built Plastic Patternmaker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

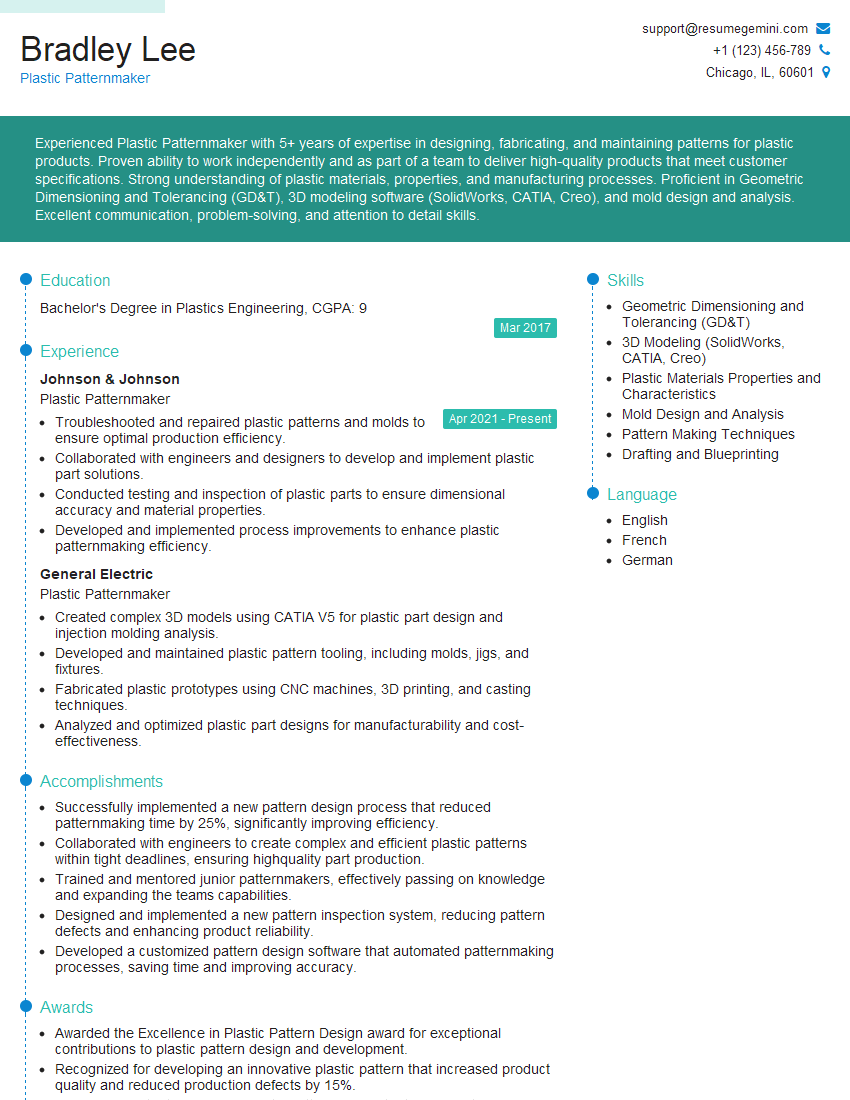

Bradley Lee

Plastic Patternmaker

Summary

Experienced Plastic Patternmaker with 5+ years of expertise in designing, fabricating, and maintaining patterns for plastic products. Proven ability to work independently and as part of a team to deliver high-quality products that meet customer specifications. Strong understanding of plastic materials, properties, and manufacturing processes. Proficient in Geometric Dimensioning and Tolerancing (GD&T), 3D modeling software (SolidWorks, CATIA, Creo), and mold design and analysis. Excellent communication, problem-solving, and attention to detail skills.

Education

Bachelor’s Degree in Plastics Engineering

March 2017

Skills

- Geometric Dimensioning and Tolerancing (GD&T)

- 3D Modeling (SolidWorks, CATIA, Creo)

- Plastic Materials Properties and Characteristics

- Mold Design and Analysis

- Pattern Making Techniques

- Drafting and Blueprinting

Work Experience

Plastic Patternmaker

- Troubleshooted and repaired plastic patterns and molds to ensure optimal production efficiency.

- Collaborated with engineers and designers to develop and implement plastic part solutions.

- Conducted testing and inspection of plastic parts to ensure dimensional accuracy and material properties.

- Developed and implemented process improvements to enhance plastic patternmaking efficiency.

Plastic Patternmaker

- Created complex 3D models using CATIA V5 for plastic part design and injection molding analysis.

- Developed and maintained plastic pattern tooling, including molds, jigs, and fixtures.

- Fabricated plastic prototypes using CNC machines, 3D printing, and casting techniques.

- Analyzed and optimized plastic part designs for manufacturability and cost-effectiveness.

Accomplishments

- Successfully implemented a new pattern design process that reduced patternmaking time by 25%, significantly improving efficiency.

- Collaborated with engineers to create complex and efficient plastic patterns within tight deadlines, ensuring highquality part production.

- Trained and mentored junior patternmakers, effectively passing on knowledge and expanding the teams capabilities.

- Designed and implemented a new pattern inspection system, reducing pattern defects and enhancing product reliability.

- Developed a customized pattern design software that automated patternmaking processes, saving time and improving accuracy.

Awards

- Awarded the Excellence in Plastic Pattern Design award for exceptional contributions to plastic pattern design and development.

- Recognized for developing an innovative plastic pattern that increased product quality and reduced production defects by 15%.

- Received a patent for a novel plastic pattern design that significantly improved material usage and reduced waste.

- Honored with a safety award for maintaining a spotless safety record and promoting a safe working environment.

Certificates

- Certified SolidWorks Professional (CSWP)

- Certified Creo Professional (CCP)

- ASME GD&T Fundamentals

- Certified Plastics Patternmaker

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Patternmaker

- Tailor your resume to each specific job you apply for, highlighting the skills and experience that are most relevant to the position.

- Use keywords from the job description in your resume to increase your chances of being selected for an interview.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Proofread your resume carefully before submitting it to ensure that it is free of errors.

- Consider getting feedback on your resume from a career counselor or professional resume writer.

Essential Experience Highlights for a Strong Plastic Patternmaker Resume

- Design and create patterns for plastic products using SolidWorks, CATIA, or Creo.

- Analyze mold designs and make recommendations for improvements to ensure optimal part quality and production efficiency.

- Fabricate and maintain patterns using various materials and techniques, including hand lay-up, vacuum forming, and CNC machining.

- Inspect patterns to ensure accuracy and compliance with specifications.

- Collaborate with engineers, designers, and production staff to develop and implement manufacturing solutions.

- Stay up-to-date on the latest industry trends and developments in plastic materials and manufacturing processes.

Frequently Asked Questions (FAQ’s) For Plastic Patternmaker

What is the role of a Plastic Patternmaker?

A Plastic Patternmaker designs, fabricates, and maintains patterns for plastic products. They work closely with engineers and designers to ensure that the patterns are accurate and meet the customer’s specifications.

What are the skills required to be a Plastic Patternmaker?

Plastic Patternmakers need strong knowledge of plastic materials, properties, and manufacturing processes. They also need to be proficient in Geometric Dimensioning and Tolerancing (GD&T), 3D modeling software, and mold design and analysis.

What are the career prospects for Plastic Patternmakers?

Plastic Patternmakers are in high demand due to the growing use of plastic products in various industries. They can find employment in a variety of settings, including manufacturing companies, mold shops, and design firms.

What is the average salary for a Plastic Patternmaker?

The average salary for a Plastic Patternmaker in the United States is around $60,000 per year.

What are the benefits of being a Plastic Patternmaker?

Plastic Patternmakers enjoy a number of benefits, including competitive salaries, job security, and the opportunity to work with cutting-edge technology.

What are the challenges of being a Plastic Patternmaker?

Plastic Patternmakers can face a number of challenges, including working with tight deadlines, complex designs, and hazardous materials.

How can I become a Plastic Patternmaker?

To become a Plastic Patternmaker, you can either complete a formal training program or learn through on-the-job experience. Many Plastic Patternmakers also have a college degree in plastics engineering or a related field.