Are you a seasoned Plastic Sheets Supervisor seeking a new career path? Discover our professionally built Plastic Sheets Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

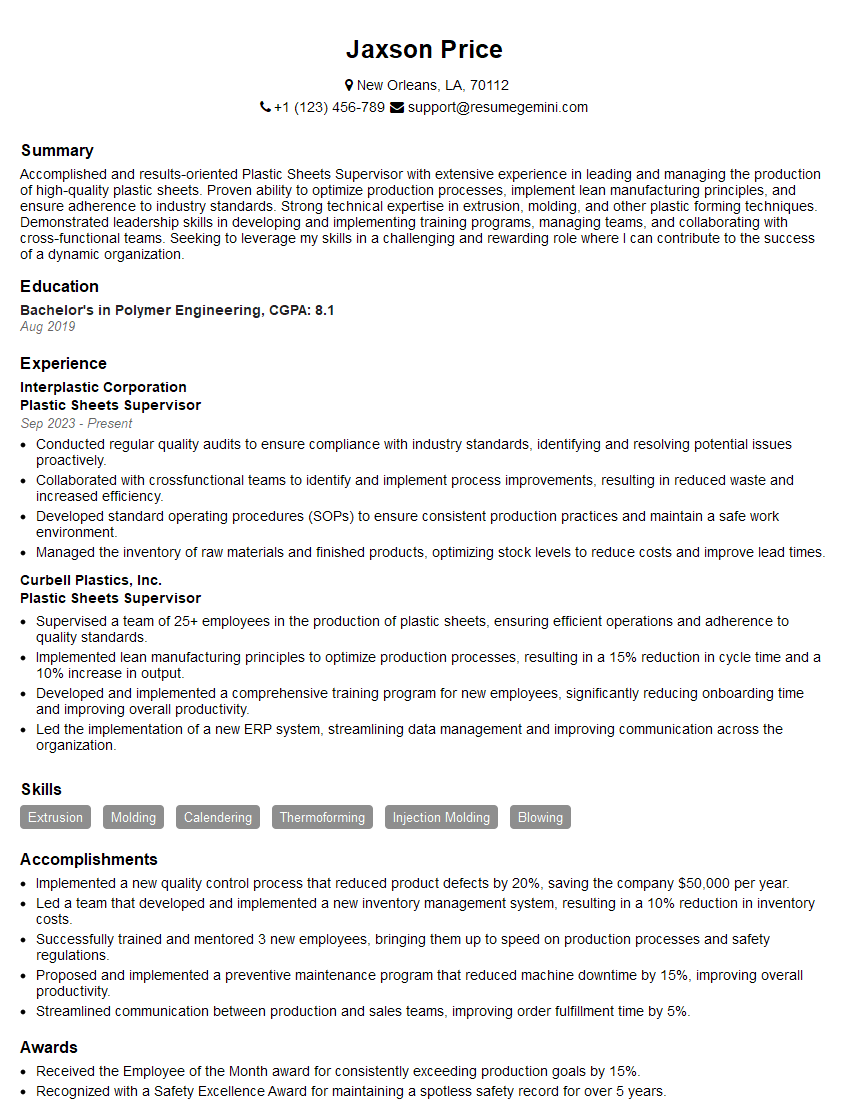

Jaxson Price

Plastic Sheets Supervisor

Summary

Accomplished and results-oriented Plastic Sheets Supervisor with extensive experience in leading and managing the production of high-quality plastic sheets. Proven ability to optimize production processes, implement lean manufacturing principles, and ensure adherence to industry standards. Strong technical expertise in extrusion, molding, and other plastic forming techniques. Demonstrated leadership skills in developing and implementing training programs, managing teams, and collaborating with cross-functional teams. Seeking to leverage my skills in a challenging and rewarding role where I can contribute to the success of a dynamic organization.

Education

Bachelor’s in Polymer Engineering

August 2019

Skills

- Extrusion

- Molding

- Calendering

- Thermoforming

- Injection Molding

- Blowing

Work Experience

Plastic Sheets Supervisor

- Conducted regular quality audits to ensure compliance with industry standards, identifying and resolving potential issues proactively.

- Collaborated with crossfunctional teams to identify and implement process improvements, resulting in reduced waste and increased efficiency.

- Developed standard operating procedures (SOPs) to ensure consistent production practices and maintain a safe work environment.

- Managed the inventory of raw materials and finished products, optimizing stock levels to reduce costs and improve lead times.

Plastic Sheets Supervisor

- Supervised a team of 25+ employees in the production of plastic sheets, ensuring efficient operations and adherence to quality standards.

- Implemented lean manufacturing principles to optimize production processes, resulting in a 15% reduction in cycle time and a 10% increase in output.

- Developed and implemented a comprehensive training program for new employees, significantly reducing onboarding time and improving overall productivity.

- Led the implementation of a new ERP system, streamlining data management and improving communication across the organization.

Accomplishments

- Implemented a new quality control process that reduced product defects by 20%, saving the company $50,000 per year.

- Led a team that developed and implemented a new inventory management system, resulting in a 10% reduction in inventory costs.

- Successfully trained and mentored 3 new employees, bringing them up to speed on production processes and safety regulations.

- Proposed and implemented a preventive maintenance program that reduced machine downtime by 15%, improving overall productivity.

- Streamlined communication between production and sales teams, improving order fulfillment time by 5%.

Awards

- Received the Employee of the Month award for consistently exceeding production goals by 15%.

- Recognized with a Safety Excellence Award for maintaining a spotless safety record for over 5 years.

- Awarded the Presidents Club Award for outstanding sales performance, exceeding targets by 25%.

- Received the Innovation Award for developing a new extrusion process that increased production efficiency by 12%.

Certificates

- Certified Plastic Processing Technician (CPP)

- Certified Plastics Extrusion Technician (CPET)

- Certified Plastics Molding Technician (CPMT)

- Certified Plastics Calendering Technician (CPCT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Sheets Supervisor

- Quantify your accomplishments with specific metrics and results whenever possible.

- Highlight your technical expertise in plastic manufacturing techniques and industry standards.

- Showcase your leadership and management skills, including your ability to motivate and develop teams.

- Demonstrate your commitment to continuous improvement and process optimization.

Essential Experience Highlights for a Strong Plastic Sheets Supervisor Resume

- Supervising a team of 25+ employees, providing guidance and leadership to ensure efficient operations and adherence to quality standards

- Implementing lean manufacturing principles to optimize production processes, resulting in improved cycle time and increased output

- Developing and implementing a comprehensive training program for new employees, significantly reducing onboarding time and improving overall productivity

- Leading the implementation of a new ERP system, streamlining data management and improving communication across the organization

- Conducting regular quality audits to ensure compliance with industry standards, identifying and resolving potential issues proactively

- Collaborating with cross-functional teams to identify and implement process improvements, resulting in reduced waste and increased efficiency

Frequently Asked Questions (FAQ’s) For Plastic Sheets Supervisor

What are the key responsibilities of a Plastic Sheets Supervisor?

Key responsibilities include supervising production teams, implementing lean manufacturing principles, developing training programs, conducting quality audits, collaborating with cross-functional teams, and managing inventory.

What are the qualifications required to become a Plastic Sheets Supervisor?

Qualifications typically include a bachelor’s degree in polymer engineering or a related field, along with experience in plastic manufacturing and supervision.

What are the career prospects for a Plastic Sheets Supervisor?

With experience and additional training, Plastic Sheets Supervisors can advance to roles such as Production Manager or Plant Manager.

What are the challenges faced by Plastic Sheets Supervisors?

Challenges can include maintaining high production standards, implementing new technologies, and managing a team in a fast-paced environment.

What are the key skills required for a Plastic Sheets Supervisor?

Key skills include technical expertise in plastic manufacturing, leadership and management abilities, communication and interpersonal skills, and a commitment to quality and safety.