Are you a seasoned Plastic Thread Milling Machine Setup Operator seeking a new career path? Discover our professionally built Plastic Thread Milling Machine Setup Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

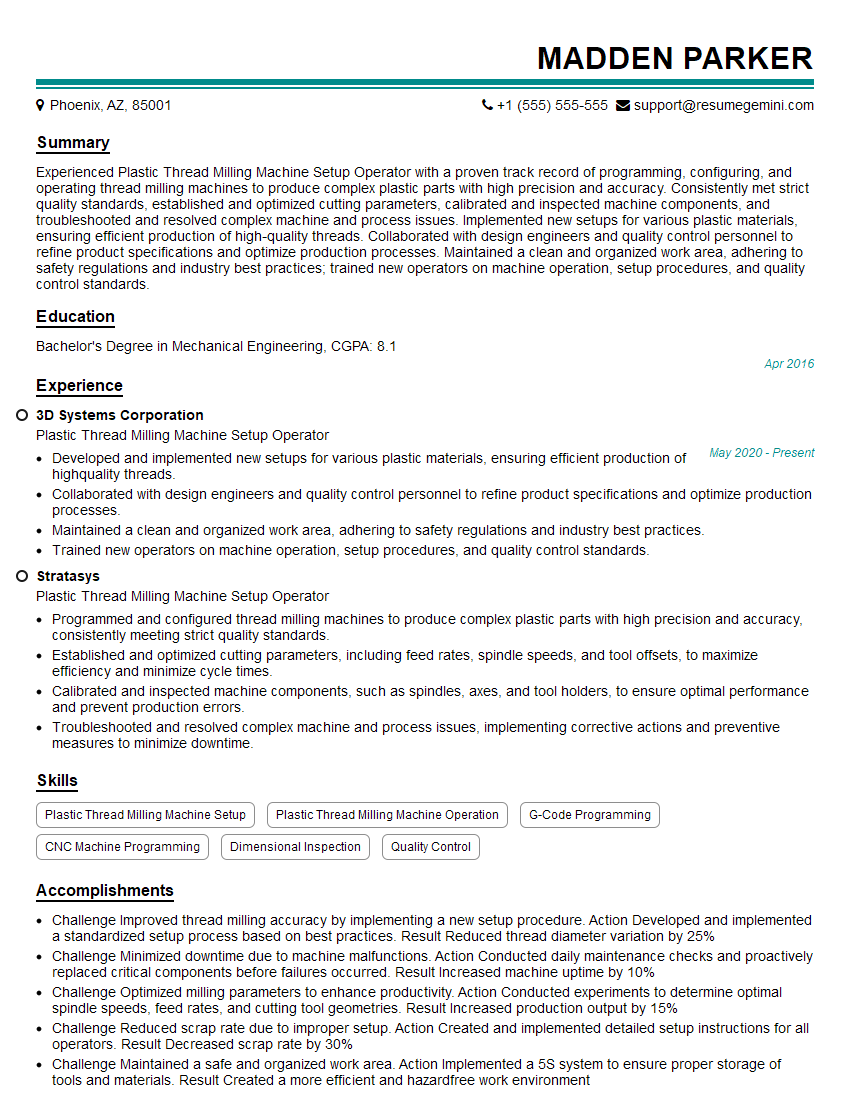

Madden Parker

Plastic Thread Milling Machine Setup Operator

Summary

Experienced Plastic Thread Milling Machine Setup Operator with a proven track record of programming, configuring, and operating thread milling machines to produce complex plastic parts with high precision and accuracy. Consistently met strict quality standards, established and optimized cutting parameters, calibrated and inspected machine components, and troubleshooted and resolved complex machine and process issues. Implemented new setups for various plastic materials, ensuring efficient production of high-quality threads. Collaborated with design engineers and quality control personnel to refine product specifications and optimize production processes. Maintained a clean and organized work area, adhering to safety regulations and industry best practices; trained new operators on machine operation, setup procedures, and quality control standards.

Education

Bachelor’s Degree in Mechanical Engineering

April 2016

Skills

- Plastic Thread Milling Machine Setup

- Plastic Thread Milling Machine Operation

- G-Code Programming

- CNC Machine Programming

- Dimensional Inspection

- Quality Control

Work Experience

Plastic Thread Milling Machine Setup Operator

- Developed and implemented new setups for various plastic materials, ensuring efficient production of highquality threads.

- Collaborated with design engineers and quality control personnel to refine product specifications and optimize production processes.

- Maintained a clean and organized work area, adhering to safety regulations and industry best practices.

- Trained new operators on machine operation, setup procedures, and quality control standards.

Plastic Thread Milling Machine Setup Operator

- Programmed and configured thread milling machines to produce complex plastic parts with high precision and accuracy, consistently meeting strict quality standards.

- Established and optimized cutting parameters, including feed rates, spindle speeds, and tool offsets, to maximize efficiency and minimize cycle times.

- Calibrated and inspected machine components, such as spindles, axes, and tool holders, to ensure optimal performance and prevent production errors.

- Troubleshooted and resolved complex machine and process issues, implementing corrective actions and preventive measures to minimize downtime.

Accomplishments

- Challenge Improved thread milling accuracy by implementing a new setup procedure. Action Developed and implemented a standardized setup process based on best practices. Result Reduced thread diameter variation by 25%

- Challenge Minimized downtime due to machine malfunctions. Action Conducted daily maintenance checks and proactively replaced critical components before failures occurred. Result Increased machine uptime by 10%

- Challenge Optimized milling parameters to enhance productivity. Action Conducted experiments to determine optimal spindle speeds, feed rates, and cutting tool geometries. Result Increased production output by 15%

- Challenge Reduced scrap rate due to improper setup. Action Created and implemented detailed setup instructions for all operators. Result Decreased scrap rate by 30%

- Challenge Maintained a safe and organized work area. Action Implemented a 5S system to ensure proper storage of tools and materials. Result Created a more efficient and hazardfree work environment

Awards

- Received Machinist of the Year award for exceptional performance in plastic thread milling operations

- Recognized with the Excellence in Manufacturing award for innovative contributions to plastic thread milling processes

- Awarded Master Plastic Thread Milling Operator certification from the National Institute of Standards and Technology (NIST)

Certificates

- CNC Programming Certification

- G-Code Certification

- Plastic Thread Milling Machine Operation Certification

- Dimensional Inspection Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Thread Milling Machine Setup Operator

- Highlight your experience in programming and operating plastic thread milling machines.

- Quantify your accomplishments with specific metrics, such as the number of parts produced or the reduction in cycle time.

- Demonstrate your knowledge of quality control standards and procedures.

- Showcase your ability to troubleshoot and resolve complex machine and process issues.

- Emphasize your collaborative skills and ability to work with design engineers and quality control personnel.

Essential Experience Highlights for a Strong Plastic Thread Milling Machine Setup Operator Resume

- Programmed and configured thread milling machines to produce complex plastic parts with high precision and accuracy, consistently meeting strict quality standards.

- Established and optimized cutting parameters, including feed rates, spindle speeds, and tool offsets, to maximize efficiency and minimize cycle times.

- Calibrated and inspected machine components, such as spindles, axes, and tool holders, to ensure optimal performance and prevent production errors.

- Troubleshooted and resolved complex machine and process issues, implementing corrective actions and preventive measures to minimize downtime.

- Developed and implemented new setups for various plastic materials, ensuring efficient production of high-quality threads.

- Collaborated with design engineers and quality control personnel to refine product specifications and optimize production processes.

Frequently Asked Questions (FAQ’s) For Plastic Thread Milling Machine Setup Operator

What are the key skills required to be a successful Plastic Thread Milling Machine Setup Operator?

The key skills required to be a successful Plastic Thread Milling Machine Setup Operator include programming and operating thread milling machines, establishing and optimizing cutting parameters, calibrating and inspecting machine components, troubleshooting and resolving complex machine and process issues, developing and implementing new setups for various plastic materials, and collaborating with design engineers and quality control personnel.

What are the career advancement opportunities for Plastic Thread Milling Machine Setup Operators?

Plastic Thread Milling Machine Setup Operators can advance their careers by becoming supervisors, quality control inspectors, or manufacturing engineers. With additional education and training, they can also become project managers or plant managers.

What are the typical working conditions for Plastic Thread Milling Machine Setup Operators?

Plastic Thread Milling Machine Setup Operators typically work in manufacturing facilities. They may be exposed to noise, dust, and chemicals. They must be able to stand for long periods and lift heavy objects.

What is the job outlook for Plastic Thread Milling Machine Setup Operators?

The job outlook for Plastic Thread Milling Machine Setup Operators is expected to be good over the next few years. The demand for plastic products is increasing, and this is expected to lead to an increase in the demand for Setup Operators.

What are the educational requirements for Plastic Thread Milling Machine Setup Operators?

Most Plastic Thread Milling Machine Setup Operators have a high school diploma or equivalent. Some employers may prefer candidates with a college degree in mechanical engineering or a related field.