Are you a seasoned Plastic Tool Maker seeking a new career path? Discover our professionally built Plastic Tool Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

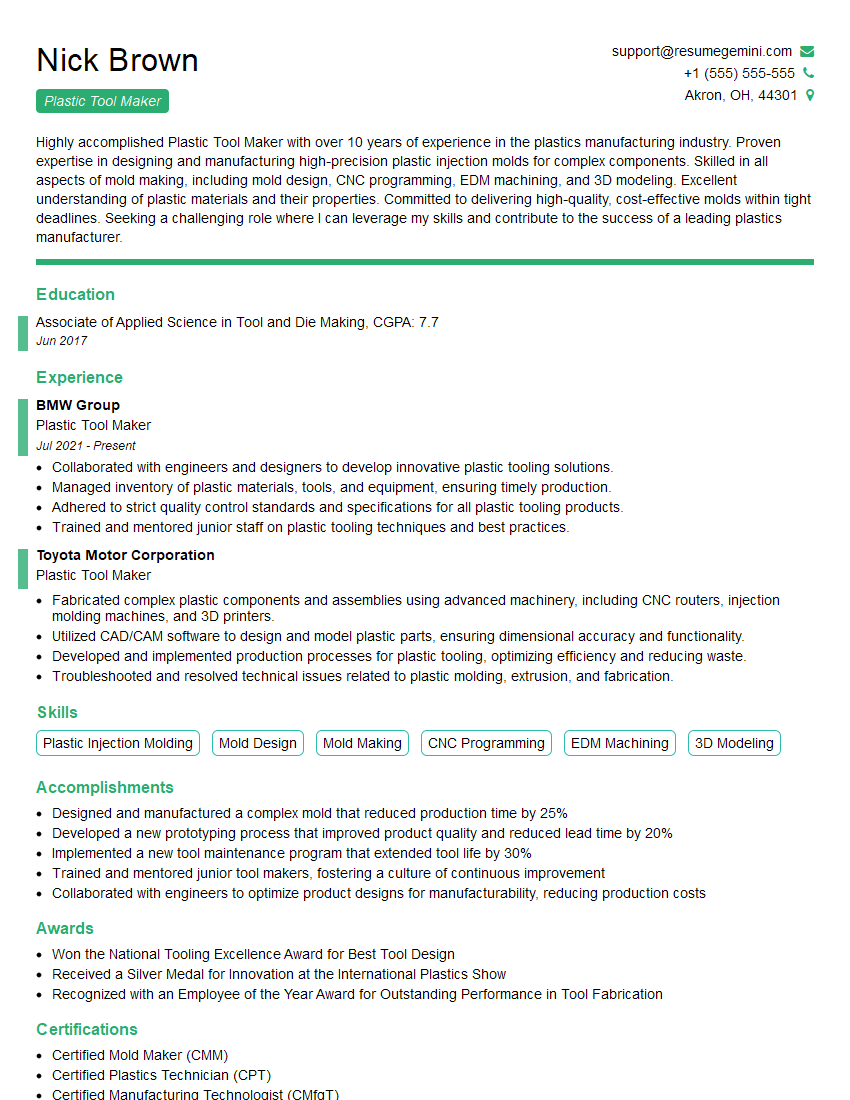

Nick Brown

Plastic Tool Maker

Summary

Highly accomplished Plastic Tool Maker with over 10 years of experience in the plastics manufacturing industry. Proven expertise in designing and manufacturing high-precision plastic injection molds for complex components. Skilled in all aspects of mold making, including mold design, CNC programming, EDM machining, and 3D modeling. Excellent understanding of plastic materials and their properties. Committed to delivering high-quality, cost-effective molds within tight deadlines. Seeking a challenging role where I can leverage my skills and contribute to the success of a leading plastics manufacturer.

Education

Associate of Applied Science in Tool and Die Making

June 2017

Skills

- Plastic Injection Molding

- Mold Design

- Mold Making

- CNC Programming

- EDM Machining

- 3D Modeling

Work Experience

Plastic Tool Maker

- Collaborated with engineers and designers to develop innovative plastic tooling solutions.

- Managed inventory of plastic materials, tools, and equipment, ensuring timely production.

- Adhered to strict quality control standards and specifications for all plastic tooling products.

- Trained and mentored junior staff on plastic tooling techniques and best practices.

Plastic Tool Maker

- Fabricated complex plastic components and assemblies using advanced machinery, including CNC routers, injection molding machines, and 3D printers.

- Utilized CAD/CAM software to design and model plastic parts, ensuring dimensional accuracy and functionality.

- Developed and implemented production processes for plastic tooling, optimizing efficiency and reducing waste.

- Troubleshooted and resolved technical issues related to plastic molding, extrusion, and fabrication.

Accomplishments

- Designed and manufactured a complex mold that reduced production time by 25%

- Developed a new prototyping process that improved product quality and reduced lead time by 20%

- Implemented a new tool maintenance program that extended tool life by 30%

- Trained and mentored junior tool makers, fostering a culture of continuous improvement

- Collaborated with engineers to optimize product designs for manufacturability, reducing production costs

Awards

- Won the National Tooling Excellence Award for Best Tool Design

- Received a Silver Medal for Innovation at the International Plastics Show

- Recognized with an Employee of the Year Award for Outstanding Performance in Tool Fabrication

Certificates

- Certified Mold Maker (CMM)

- Certified Plastics Technician (CPT)

- Certified Manufacturing Technologist (CMfgT)

- ISO 9001 Lead Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Tool Maker

- Highlight your experience and expertise in plastic injection molding, mold design, and mold making.

- Showcase your proficiency in using CNC programming and EDM machining.

- Quantify your accomplishments and provide specific examples of your contributions.

- Tailor your resume to the specific job you are applying for, highlighting the skills and experience most relevant to the role.

Essential Experience Highlights for a Strong Plastic Tool Maker Resume

- Design and develop plastic injection molds for a wide range of products.

- Analyze product designs and determine the appropriate mold design and materials.

- Operate CNC milling and EDM machines to create mold components with high precision.

- Program and operate CNC machines to cut and machine mold components.

- Troubleshoot and repair molds to ensure optimal performance and prevent production delays.

- Train and supervise junior tool makers.

- Maintain a clean and organized work area to promote safety and efficiency.

Frequently Asked Questions (FAQ’s) For Plastic Tool Maker

What are the primary responsibilities of a Plastic Tool Maker?

Plastic Tool Makers are responsible for designing, developing, and manufacturing plastic injection molds. They work closely with engineers and product designers to ensure that the molds meet the required specifications. They also operate and maintain CNC machines and other equipment used in the mold-making process.

What skills are essential for a Plastic Tool Maker?

Essential skills for a Plastic Tool Maker include a strong understanding of plastic materials and their properties, proficiency in mold design and manufacturing techniques, and expertise in using CNC programming and EDM machining. They must also have excellent problem-solving skills and be able to work independently and as part of a team.

What are the career opportunities for Plastic Tool Makers?

Plastic Tool Makers can pursue careers in various industries, including automotive, aerospace, medical, and consumer products. They can work in mold-making shops, manufacturing plants, or research and development facilities. With experience and additional training, they can advance to supervisory or management positions.

How can I prepare for a career as a Plastic Tool Maker?

To prepare for a career as a Plastic Tool Maker, you can obtain an associate degree or certificate in tool and die making or a related field. You can also gain experience through apprenticeships or internships. Additionally, staying updated on the latest technologies and industry trends is crucial.

What is the job outlook for Plastic Tool Makers?

The job outlook for Plastic Tool Makers is expected to grow in the coming years. The increasing demand for plastic products in various industries is driving the need for skilled professionals who can design and manufacture high-quality molds.