Are you a seasoned Plastics Fabricator seeking a new career path? Discover our professionally built Plastics Fabricator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

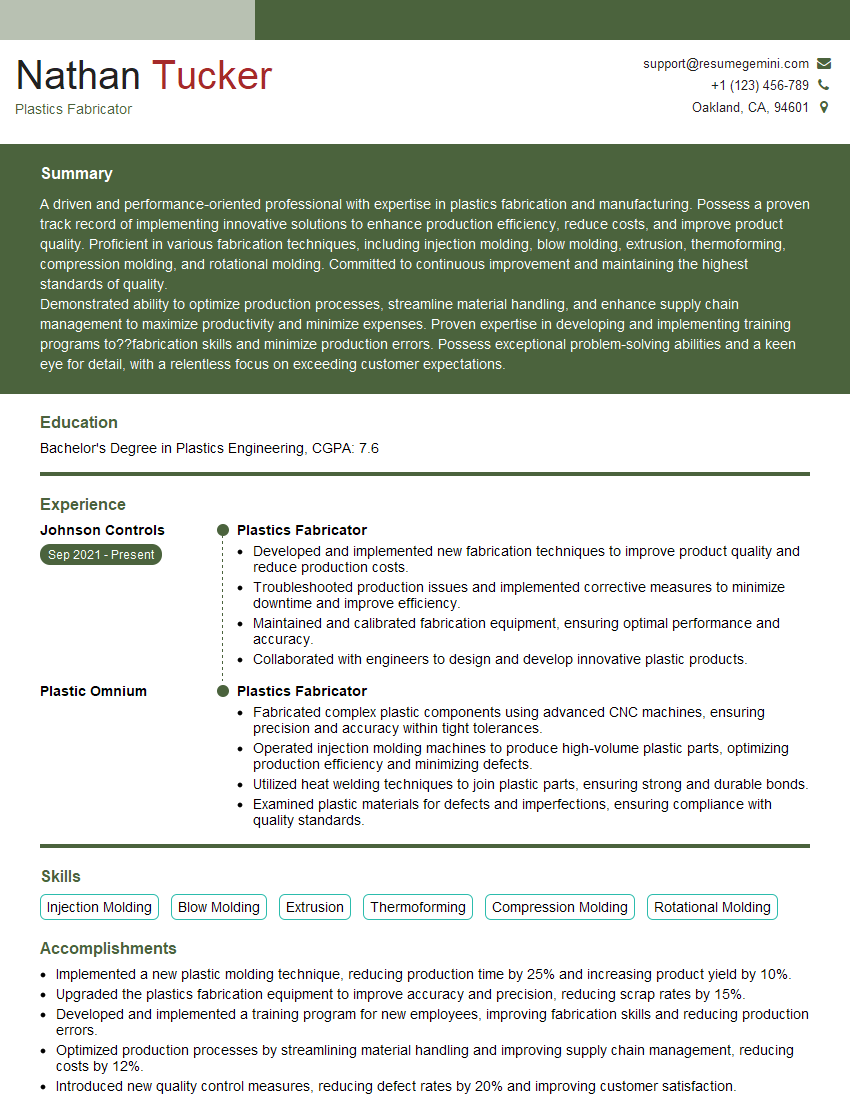

Nathan Tucker

Plastics Fabricator

Summary

A driven and performance-oriented professional with expertise in plastics fabrication and manufacturing. Possess a proven track record of implementing innovative solutions to enhance production efficiency, reduce costs, and improve product quality. Proficient in various fabrication techniques, including injection molding, blow molding, extrusion, thermoforming, compression molding, and rotational molding. Committed to continuous improvement and maintaining the highest standards of quality.

Demonstrated ability to optimize production processes, streamline material handling, and enhance supply chain management to maximize productivity and minimize expenses. Proven expertise in developing and implementing training programs to??fabrication skills and minimize production errors. Possess exceptional problem-solving abilities and a keen eye for detail, with a relentless focus on exceeding customer expectations.

Education

Bachelor’s Degree in Plastics Engineering

August 2017

Skills

- Injection Molding

- Blow Molding

- Extrusion

- Thermoforming

- Compression Molding

- Rotational Molding

Work Experience

Plastics Fabricator

- Developed and implemented new fabrication techniques to improve product quality and reduce production costs.

- Troubleshooted production issues and implemented corrective measures to minimize downtime and improve efficiency.

- Maintained and calibrated fabrication equipment, ensuring optimal performance and accuracy.

- Collaborated with engineers to design and develop innovative plastic products.

Plastics Fabricator

- Fabricated complex plastic components using advanced CNC machines, ensuring precision and accuracy within tight tolerances.

- Operated injection molding machines to produce high-volume plastic parts, optimizing production efficiency and minimizing defects.

- Utilized heat welding techniques to join plastic parts, ensuring strong and durable bonds.

- Examined plastic materials for defects and imperfections, ensuring compliance with quality standards.

Accomplishments

- Implemented a new plastic molding technique, reducing production time by 25% and increasing product yield by 10%.

- Upgraded the plastics fabrication equipment to improve accuracy and precision, reducing scrap rates by 15%.

- Developed and implemented a training program for new employees, improving fabrication skills and reducing production errors.

- Optimized production processes by streamlining material handling and improving supply chain management, reducing costs by 12%.

- Introduced new quality control measures, reducing defect rates by 20% and improving customer satisfaction.

Awards

- Recognized with the Excellence in Plastics Fabrication Award for consistently producing highquality plastic components.

- Received the Innovation Award for developing a novel plastic composite material with enhanced strength and durability.

- Honored with the Safety Excellence Award for implementing best practices in plastics fabrication, ensuring a safe work environment.

- Recognized with the Employee of the Year Award for outstanding contributions to the plastics fabrication department.

Certificates

- Certified Plastics Technician (CPT)

- Certified Injection Molding Technician (CIMT)

- Certified Blow Molding Technician (CBMT)

- Certified Extrusion Technician (CET)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastics Fabricator

- Highlight your technical skills and experience in plastics fabrication techniques, including injection molding, blow molding, and extrusion.

- Quantify your accomplishments with specific metrics and data to demonstrate your impact on production efficiency and product quality.

- Showcase your problem-solving abilities and provide examples of how you have overcome challenges in the plastics fabrication process.

- Emphasize your commitment to safety and maintaining a clean and organized work environment.

- Tailor your resume to the specific job you are applying for and highlight the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Plastics Fabricator Resume

- Operate and maintain plastics fabrication equipment to produce high-quality plastic products.

- Develop and implement new fabrication techniques to improve efficiency and product quality.

- Troubleshoot and resolve production issues to minimize downtime and ensure smooth operations.

- Monitor production processes and make adjustments as needed to optimize output and meet customer specifications.

- Adhere to safety guidelines and maintain a clean and organized work environment.

- Stay abreast of industry trends and advancements in plastics fabrication to identify opportunities for improvement.

- Work effectively as part of a team and collaborate with other departments to achieve shared goals.

Frequently Asked Questions (FAQ’s) For Plastics Fabricator

What are the key skills required to be a successful Plastics Fabricator?

The key skills required to be a successful Plastics Fabricator include proficiency in various fabrication techniques, such as injection molding, blow molding, extrusion, thermoforming, compression molding, and rotational molding. Additionally, a strong understanding of plastics properties, material handling, and quality control is essential. Attention to detail, problem-solving abilities, and a commitment to safety are also highly valued.

What are the different types of plastics fabrication techniques?

The most common plastics fabrication techniques include injection molding, blow molding, extrusion, thermoforming, compression molding, and rotational molding. Each technique has its own unique advantages and is suitable for different types of plastic products. Injection molding is used to produce complex parts with high precision, while blow molding is ideal for creating hollow products with uniform wall thickness. Extrusion is a continuous process used to create plastic sheets, pipes, and profiles, while thermoforming involves heating a plastic sheet and forming it over a mold. Compression molding and rotational molding are used to produce large, complex parts with high strength and durability.

What are the career prospects for Plastics Fabricators?

The career prospects for Plastics Fabricators are generally positive, with increasing demand for skilled professionals in the manufacturing industry. Plastics are used in a wide range of products, from automotive parts to medical devices, and the demand for plastics fabrication services is expected to grow as the use of plastics continues to expand. With experience and additional training, Plastics Fabricators can advance to supervisory or management roles, or specialize in specific fabrication techniques or applications.

What are the safety precautions that should be taken when working with plastics?

Plastics fabrication can involve working with hazardous materials and machinery, so it is important to take appropriate safety precautions. These precautions include wearing protective clothing and equipment, such as gloves, safety glasses, and respirators, to protect against exposure to chemicals, dust, and fumes. Proper ventilation is also essential to prevent the buildup of harmful vapors and gases. Additionally, it is important to follow established safety protocols and procedures, and to be aware of the potential hazards associated with the specific materials and equipment being used.

What are some tips for writing a standout Plastics Fabricator resume?

To write a standout Plastics Fabricator resume, highlight your technical skills and experience in plastics fabrication techniques, such as injection molding, blow molding, and extrusion. Quantify your accomplishments with specific metrics and data to demonstrate your impact on production efficiency and product quality. Showcase your problem-solving abilities and provide examples of how you have overcome challenges in the plastics fabrication process. Emphasize your commitment to safety and maintaining a clean and organized work environment. Tailor your resume to the specific job you are applying for and highlight the skills and experience that are most relevant to the position.

What are the different industries that employ Plastics Fabricators?

Plastics Fabricators find employment in a variety of industries, including automotive, aerospace, construction, electronics, medical, and consumer products. Plastics are used in a wide range of products, from car parts to medical devices, and Plastics Fabricators play a vital role in the manufacturing process. They work in factories and production facilities, and may be responsible for operating and maintaining plastics fabrication equipment, developing and implementing new fabrication techniques, and ensuring the quality of plastic products.

What are the educational requirements to become a Plastics Fabricator?

Although formal education requirements vary, most Plastics Fabricators have a high school diploma or equivalent. Some employers may prefer candidates with a post-secondary degree or certificate in plastics technology or a related field. Additionally, many Plastics Fabricators complete on-the-job training programs to learn the specific skills and techniques required for the job.

What are the advancement opportunities for Plastics Fabricators?

With experience and additional training, Plastics Fabricators can advance to supervisory or management roles, or specialize in specific fabrication techniques or applications. They may also become involved in research and development, or start their own plastics fabrication business. The plastics industry is constantly evolving, so Plastics Fabricators who stay up-to-date on the latest techniques and technologies will have the best opportunities for advancement.