Are you a seasoned Plate Former seeking a new career path? Discover our professionally built Plate Former Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

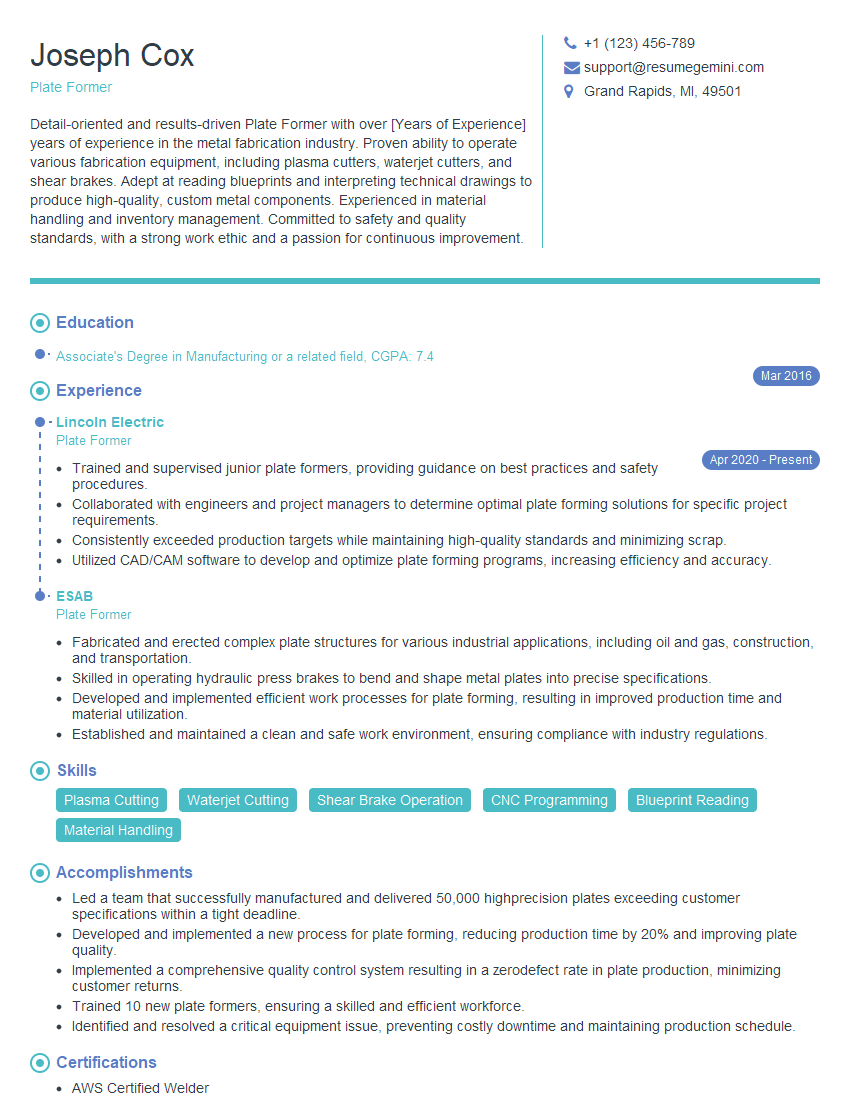

Joseph Cox

Plate Former

Summary

Detail-oriented and results-driven Plate Former with over [Years of Experience] years of experience in the metal fabrication industry. Proven ability to operate various fabrication equipment, including plasma cutters, waterjet cutters, and shear brakes. Adept at reading blueprints and interpreting technical drawings to produce high-quality, custom metal components. Experienced in material handling and inventory management. Committed to safety and quality standards, with a strong work ethic and a passion for continuous improvement.

Education

Associate’s Degree in Manufacturing or a related field

March 2016

Skills

- Plasma Cutting

- Waterjet Cutting

- Shear Brake Operation

- CNC Programming

- Blueprint Reading

- Material Handling

Work Experience

Plate Former

- Trained and supervised junior plate formers, providing guidance on best practices and safety procedures.

- Collaborated with engineers and project managers to determine optimal plate forming solutions for specific project requirements.

- Consistently exceeded production targets while maintaining high-quality standards and minimizing scrap.

- Utilized CAD/CAM software to develop and optimize plate forming programs, increasing efficiency and accuracy.

Plate Former

- Fabricated and erected complex plate structures for various industrial applications, including oil and gas, construction, and transportation.

- Skilled in operating hydraulic press brakes to bend and shape metal plates into precise specifications.

- Developed and implemented efficient work processes for plate forming, resulting in improved production time and material utilization.

- Established and maintained a clean and safe work environment, ensuring compliance with industry regulations.

Accomplishments

- Led a team that successfully manufactured and delivered 50,000 highprecision plates exceeding customer specifications within a tight deadline.

- Developed and implemented a new process for plate forming, reducing production time by 20% and improving plate quality.

- Implemented a comprehensive quality control system resulting in a zerodefect rate in plate production, minimizing customer returns.

- Trained 10 new plate formers, ensuring a skilled and efficient workforce.

- Identified and resolved a critical equipment issue, preventing costly downtime and maintaining production schedule.

Certificates

- AWS Certified Welder

- OSHA 30-Hour Safety Training

- NFPA 70E Electrical Safety

- First Aid and CPR Certified

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plate Former

- Highlight your experience in operating different types of fabrication equipment, including plasma cutters, waterjet cutters, and shear brakes.

- Showcase your ability to read and interpret blueprints and technical drawings accurately.

- Emphasize your attention to detail and commitment to producing high-quality work.

- Demonstrate your knowledge of safety regulations and best practices in the metal fabrication industry.

Essential Experience Highlights for a Strong Plate Former Resume

- Operate plasma cutters, waterjet cutters, and shear brakes to cut and shape metal plates according to specified dimensions.

- Interpret blueprints and technical drawings to determine material requirements and fabrication processes.

- Set up and calibrate fabrication equipment to ensure accurate and efficient operation.

- Perform material handling tasks, including loading and unloading raw materials and finished products.

- Maintain a clean and organized work area, adhering to safety regulations and best practices.

- Troubleshoot and resolve equipment malfunctions, ensuring minimal downtime.

- Collaborate with other team members to achieve production goals and meet customer specifications.

Frequently Asked Questions (FAQ’s) For Plate Former

What is a Plate Former?

A Plate Former is a skilled professional who operates machines to shape and cut metal plates. They use specialized equipment like plasma cutters, waterjet cutters, and shear brakes to create custom metal components based on blueprints and technical drawings.

What skills are required to become a Plate Former?

Plate Formers typically require a combination of technical skills, including plasma cutting, waterjet cutting, shear brake operation, CNC programming, blueprint reading, and material handling. Strong attention to detail, problem-solving abilities, and a commitment to safety are also essential.

What industries employ Plate Formers?

Plate Formers are in demand across various industries that utilize metal fabrication processes, such as construction, automotive, aerospace, shipbuilding, and manufacturing.

What is the average salary for a Plate Former?

The salary of a Plate Former can vary depending on experience, location, and industry. According to Salary.com, the average annual salary for a Plate Former in the United States is around $55,000.

What are the career advancement opportunities for Plate Formers?

Plate Formers with experience and expertise can advance to supervisory roles or specialize in specific fabrication techniques. They may also pursue opportunities in design, engineering, or quality control.

Is there a high demand for Plate Formers?

Yes, Plate Formers are in high demand due to the increasing use of metal fabrication in various industries. The aging workforce and the need for skilled tradespeople further contribute to the demand.

What are the working conditions like for Plate Formers?

Plate Formers typically work in manufacturing facilities or fabrication shops. The work can be physically demanding, involving standing for long periods, operating heavy machinery, and handling materials. Safety precautions and protective gear are essential to minimize risks.

What training is required to become a Plate Former?

While formal training is not always required, many Plate Formers receive on-the-job training or complete apprenticeship programs. Technical schools and community colleges also offer courses and programs in metal fabrication, providing a foundation for a career as a Plate Former.