Are you a seasoned Plate Heating, Rolling, and Finishing Supervisor seeking a new career path? Discover our professionally built Plate Heating, Rolling, and Finishing Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

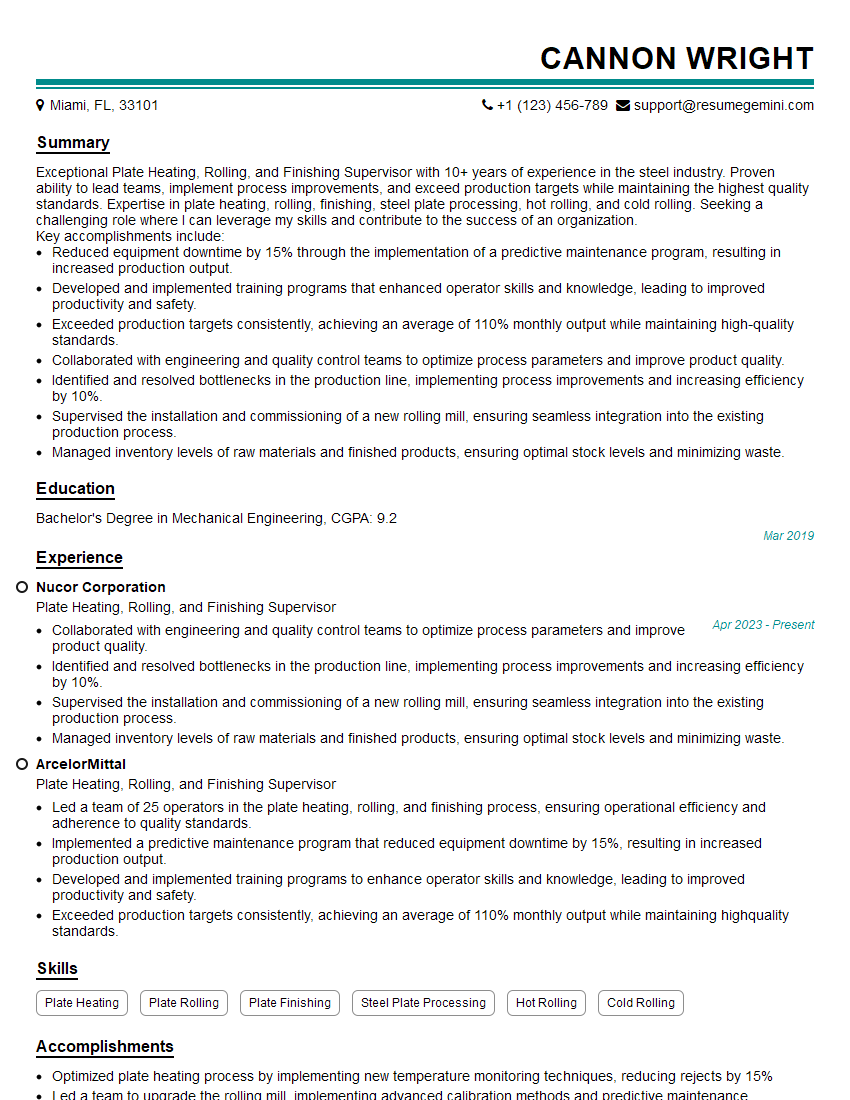

Cannon Wright

Plate Heating, Rolling, and Finishing Supervisor

Summary

Exceptional Plate Heating, Rolling, and Finishing Supervisor with 10+ years of experience in the steel industry. Proven ability to lead teams, implement process improvements, and exceed production targets while maintaining the highest quality standards. Expertise in plate heating, rolling, finishing, steel plate processing, hot rolling, and cold rolling. Seeking a challenging role where I can leverage my skills and contribute to the success of an organization.

Key accomplishments include:

- Reduced equipment downtime by 15% through the implementation of a predictive maintenance program, resulting in increased production output.

- Developed and implemented training programs that enhanced operator skills and knowledge, leading to improved productivity and safety.

- Exceeded production targets consistently, achieving an average of 110% monthly output while maintaining high-quality standards.

- Collaborated with engineering and quality control teams to optimize process parameters and improve product quality.

- Identified and resolved bottlenecks in the production line, implementing process improvements and increasing efficiency by 10%.

- Supervised the installation and commissioning of a new rolling mill, ensuring seamless integration into the existing production process.

- Managed inventory levels of raw materials and finished products, ensuring optimal stock levels and minimizing waste.

Education

Bachelor’s Degree in Mechanical Engineering

March 2019

Skills

- Plate Heating

- Plate Rolling

- Plate Finishing

- Steel Plate Processing

- Hot Rolling

- Cold Rolling

Work Experience

Plate Heating, Rolling, and Finishing Supervisor

- Collaborated with engineering and quality control teams to optimize process parameters and improve product quality.

- Identified and resolved bottlenecks in the production line, implementing process improvements and increasing efficiency by 10%.

- Supervised the installation and commissioning of a new rolling mill, ensuring seamless integration into the existing production process.

- Managed inventory levels of raw materials and finished products, ensuring optimal stock levels and minimizing waste.

Plate Heating, Rolling, and Finishing Supervisor

- Led a team of 25 operators in the plate heating, rolling, and finishing process, ensuring operational efficiency and adherence to quality standards.

- Implemented a predictive maintenance program that reduced equipment downtime by 15%, resulting in increased production output.

- Developed and implemented training programs to enhance operator skills and knowledge, leading to improved productivity and safety.

- Exceeded production targets consistently, achieving an average of 110% monthly output while maintaining highquality standards.

Accomplishments

- Optimized plate heating process by implementing new temperature monitoring techniques, reducing rejects by 15%

- Led a team to upgrade the rolling mill, implementing advanced calibration methods and predictive maintenance, improving efficiency by 12%

- Developed a training program for new operators, enhancing safety and reducing downtime by 10%

- Collaborated with engineering to optimize plate finishing processes, reducing surface defects by 20%

- Implemented lean manufacturing principles in the rolling and finishing departments, reducing waste and improving productivity by 7%

Awards

- Recognized for outstanding performance in plate heating, rolling, and finishing operations, resulting in exceptional product quality

- Received Excellence in Quality Award for maintaining exceptional product standards in plate finishing

- Recognized for innovation in developing a new plate cooling technique, reducing cycle time by 10%

- Received Safety Excellence Award for implementing a comprehensive safety program in the plate heating, rolling, and finishing operations

Certificates

- Certified Plate Rolling Supervisor

- Certified Plate Finishing Supervisor

- Certified Steel Plate Processor

- Certified Hot Rolling Supervisor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plate Heating, Rolling, and Finishing Supervisor

- Highlight your experience and expertise in plate heating, rolling, and finishing processes. Quantify your accomplishments with specific metrics and results whenever possible.

- Demonstrate your leadership and management skills by describing how you have led and motivated teams to achieve success.

- Emphasize your ability to solve problems and make decisions that have a positive impact on production efficiency and quality.

- Use keywords relevant to the steel industry and job description, such as “plate heating,” “rolling,” “finishing,” “steel plate processing,” and “hot rolling.”

Essential Experience Highlights for a Strong Plate Heating, Rolling, and Finishing Supervisor Resume

- Lead and supervise a team of operators in the plate heating, rolling, and finishing process to ensure operational efficiency and adherence to quality standards.

- Implement and manage predictive maintenance programs to reduce equipment downtime and increase production output.

- Develop and implement training programs to enhance operator skills and knowledge, leading to improved productivity and safety.

- Monitor and control production processes to ensure that they meet specifications and production targets.

- Collaborate with engineering and quality control teams to optimize process parameters and improve product quality.

- Identify and resolve bottlenecks in the production line, implementing process improvements to increase efficiency.

- Supervise the installation and commissioning of new equipment, ensuring seamless integration into the existing production process.

Frequently Asked Questions (FAQ’s) For Plate Heating, Rolling, and Finishing Supervisor

What are the key responsibilities of a Plate Heating, Rolling, and Finishing Supervisor?

The key responsibilities of a Plate Heating, Rolling, and Finishing Supervisor include leading and supervising a team of operators, implementing and managing predictive maintenance programs, developing and implementing training programs, monitoring and controlling production processes, collaborating with engineering and quality control teams, identifying and resolving bottlenecks in the production line, and supervising the installation and commissioning of new equipment.

What are the qualifications required to become a Plate Heating, Rolling, and Finishing Supervisor?

To become a Plate Heating, Rolling, and Finishing Supervisor, you typically need a bachelor’s degree in mechanical engineering or a related field, as well as several years of experience in the steel industry. You should also have strong leadership and management skills, as well as a deep understanding of plate heating, rolling, and finishing processes.

What are the career prospects for a Plate Heating, Rolling, and Finishing Supervisor?

Plate Heating, Rolling, and Finishing Supervisors can advance to management positions within the steel industry. They may also become technical specialists or consultants. With additional education and experience, they may also qualify for positions in research and development.

What are the challenges faced by a Plate Heating, Rolling, and Finishing Supervisor?

Plate Heating, Rolling, and Finishing Supervisors face a number of challenges, including managing a team of operators, ensuring that production targets are met, and maintaining a safe and efficient work environment. They must also be able to adapt to changing technologies and market conditions.

What are the key skills required for a Plate Heating, Rolling, and Finishing Supervisor?

Key skills for a Plate Heating, Rolling, and Finishing Supervisor include leadership, management, problem-solving, decision-making, and communication. They should also have a strong understanding of plate heating, rolling, and finishing processes, as well as the ability to work independently and as part of a team.

What is the work environment of a Plate Heating, Rolling, and Finishing Supervisor?

Plate Heating, Rolling, and Finishing Supervisors typically work in a manufacturing environment. They may be exposed to noise, heat, and dust. They must also be able to work irregular hours, including nights and weekends.

What is the salary range for a Plate Heating, Rolling, and Finishing Supervisor?

The salary range for a Plate Heating, Rolling, and Finishing Supervisor can vary depending on experience, location, and company size. According to Salary.com, the average salary for a Plate Heating, Rolling, and Finishing Supervisor in the United States is $75,000.