Are you a seasoned Plate Maker seeking a new career path? Discover our professionally built Plate Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

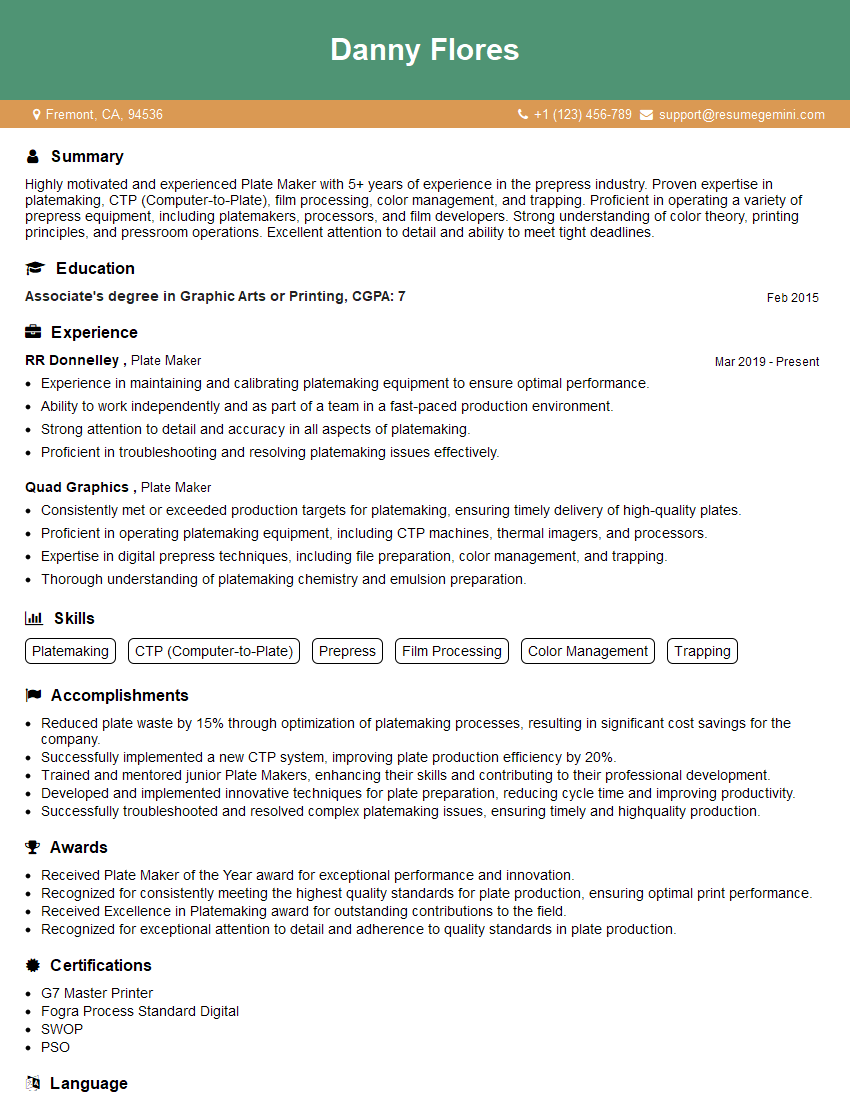

Danny Flores

Plate Maker

Summary

Highly motivated and experienced Plate Maker with 5+ years of experience in the prepress industry. Proven expertise in platemaking, CTP (Computer-to-Plate), film processing, color management, and trapping. Proficient in operating a variety of prepress equipment, including platemakers, processors, and film developers. Strong understanding of color theory, printing principles, and pressroom operations. Excellent attention to detail and ability to meet tight deadlines.

Education

Associate’s degree in Graphic Arts or Printing

February 2015

Skills

- Platemaking

- CTP (Computer-to-Plate)

- Prepress

- Film Processing

- Color Management

- Trapping

Work Experience

Plate Maker

- Experience in maintaining and calibrating platemaking equipment to ensure optimal performance.

- Ability to work independently and as part of a team in a fast-paced production environment.

- Strong attention to detail and accuracy in all aspects of platemaking.

- Proficient in troubleshooting and resolving platemaking issues effectively.

Plate Maker

- Consistently met or exceeded production targets for platemaking, ensuring timely delivery of high-quality plates.

- Proficient in operating platemaking equipment, including CTP machines, thermal imagers, and processors.

- Expertise in digital prepress techniques, including file preparation, color management, and trapping.

- Thorough understanding of platemaking chemistry and emulsion preparation.

Accomplishments

- Reduced plate waste by 15% through optimization of platemaking processes, resulting in significant cost savings for the company.

- Successfully implemented a new CTP system, improving plate production efficiency by 20%.

- Trained and mentored junior Plate Makers, enhancing their skills and contributing to their professional development.

- Developed and implemented innovative techniques for plate preparation, reducing cycle time and improving productivity.

- Successfully troubleshooted and resolved complex platemaking issues, ensuring timely and highquality production.

Awards

- Received Plate Maker of the Year award for exceptional performance and innovation.

- Recognized for consistently meeting the highest quality standards for plate production, ensuring optimal print performance.

- Received Excellence in Platemaking award for outstanding contributions to the field.

- Recognized for exceptional attention to detail and adherence to quality standards in plate production.

Certificates

- G7 Master Printer

- Fogra Process Standard Digital

- SWOP

- PSO

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plate Maker

- Highlight your skills and experience in the prepress industry, specifically in platemaking.

- Showcase your knowledge of color management, trapping, and printing principles.

- Quantify your accomplishments and results to demonstrate your impact on the organization.

- Tailor your resume to the specific requirements of each job you apply for.

Essential Experience Highlights for a Strong Plate Maker Resume

- Prepare printing plates for offset lithographic presses using computer-to-plate (CTP) technology

- Operate platemaking equipment, including platemakers, processors, and film developers

- Calibrate and maintain prepress equipment to ensure optimal printing quality

- Perform color matching and color correction to ensure accurate color reproduction

- Inspect plates for defects and make necessary corrections

- Maintain a clean and organized work area

- Adhere to safety regulations and maintain a safe work environment

Frequently Asked Questions (FAQ’s) For Plate Maker

What are the key responsibilities of a Plate Maker?

Plate Makers are responsible for preparing printing plates for offset lithographic presses using computer-to-plate (CTP) technology. They operate platemaking equipment, including platemakers, processors, and film developers, and calibrate and maintain prepress equipment to ensure optimal printing quality.

What skills are required to be a Plate Maker?

Plate Makers need to have strong knowledge of color management, trapping, and printing principles, as well as experience in operating platemaking equipment. They also need to be detail-oriented and able to meet tight deadlines.

What is the work environment of a Plate Maker like?

Plate Makers typically work in a prepress department of a printing company. They may work in a team environment with other prepress technicians or independently. They may also work overtime to meet deadlines.

What is the salary range for a Plate Maker?

The salary range for a Plate Maker can vary depending on their experience, skills, and location. According to Indeed, the average salary for a Plate Maker in the United States is around $45,000 per year.

What are the career prospects for a Plate Maker?

Plate Makers can advance their careers by becoming supervisors or managers in the prepress department. They may also specialize in a particular area of prepress, such as color management or trapping.

What is the job outlook for a Plate Maker?

The job outlook for Plate Makers is expected to decline over the next few years due to the increasing use of digital printing technology. However, there will still be a need for skilled Plate Makers in the printing industry.