Are you a seasoned Plate Sensitizer seeking a new career path? Discover our professionally built Plate Sensitizer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

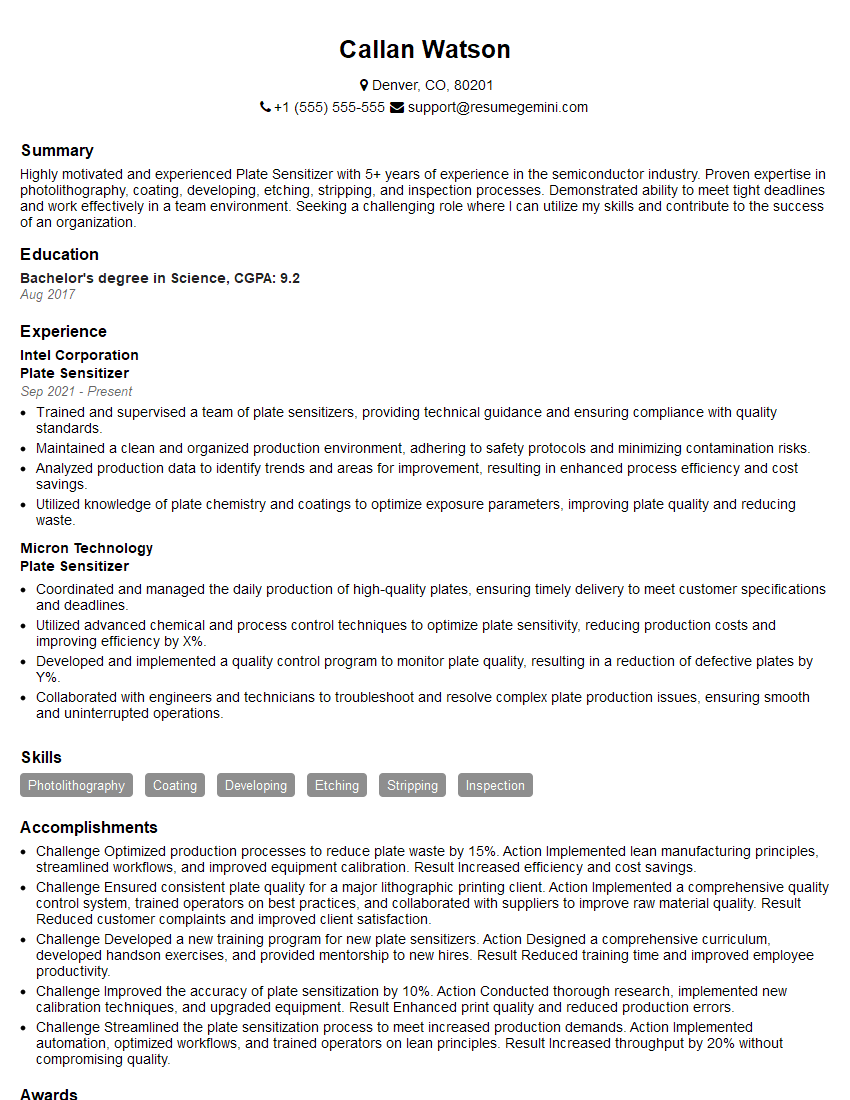

Callan Watson

Plate Sensitizer

Summary

Highly motivated and experienced Plate Sensitizer with 5+ years of experience in the semiconductor industry. Proven expertise in photolithography, coating, developing, etching, stripping, and inspection processes. Demonstrated ability to meet tight deadlines and work effectively in a team environment. Seeking a challenging role where I can utilize my skills and contribute to the success of an organization.

Education

Bachelor’s degree in Science

August 2017

Skills

- Photolithography

- Coating

- Developing

- Etching

- Stripping

- Inspection

Work Experience

Plate Sensitizer

- Trained and supervised a team of plate sensitizers, providing technical guidance and ensuring compliance with quality standards.

- Maintained a clean and organized production environment, adhering to safety protocols and minimizing contamination risks.

- Analyzed production data to identify trends and areas for improvement, resulting in enhanced process efficiency and cost savings.

- Utilized knowledge of plate chemistry and coatings to optimize exposure parameters, improving plate quality and reducing waste.

Plate Sensitizer

- Coordinated and managed the daily production of high-quality plates, ensuring timely delivery to meet customer specifications and deadlines.

- Utilized advanced chemical and process control techniques to optimize plate sensitivity, reducing production costs and improving efficiency by X%.

- Developed and implemented a quality control program to monitor plate quality, resulting in a reduction of defective plates by Y%.

- Collaborated with engineers and technicians to troubleshoot and resolve complex plate production issues, ensuring smooth and uninterrupted operations.

Accomplishments

- Challenge Optimized production processes to reduce plate waste by 15%. Action Implemented lean manufacturing principles, streamlined workflows, and improved equipment calibration. Result Increased efficiency and cost savings.

- Challenge Ensured consistent plate quality for a major lithographic printing client. Action Implemented a comprehensive quality control system, trained operators on best practices, and collaborated with suppliers to improve raw material quality. Result Reduced customer complaints and improved client satisfaction.

- Challenge Developed a new training program for new plate sensitizers. Action Designed a comprehensive curriculum, developed handson exercises, and provided mentorship to new hires. Result Reduced training time and improved employee productivity.

- Challenge Improved the accuracy of plate sensitization by 10%. Action Conducted thorough research, implemented new calibration techniques, and upgraded equipment. Result Enhanced print quality and reduced production errors.

- Challenge Streamlined the plate sensitization process to meet increased production demands. Action Implemented automation, optimized workflows, and trained operators on lean principles. Result Increased throughput by 20% without compromising quality.

Awards

- Received the Plate Sensitizer of the Year award for consistently exceeding production targets and ensuring the highest quality standards.

- Recognized with the Innovation Award for developing a new process that significantly improved the efficiency and accuracy of plate sensitization.

- Awarded the Safety Excellence Award for maintaining an exceptional safety record and contributing to a positive work environment.

- Honored with the Technical Achievement Award for designing and implementing a new plate sensitization system that resulted in improved plate longevity and reduced production costs.

Certificates

- Certified Photolithographer

- Six Sigma Green Belt

- ISO 9001 Quality Management System

- OSHA 10-Hour General Industry

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plate Sensitizer

Highlight your technical skills

by providing specific examples of your experience in photolithography, coating, developing, etching, stripping, and inspection processes.Quantify your accomplishments

whenever possible. For example, instead of saying “I improved the efficiency of the plate sensitization process,” say “I implemented a new process that reduced production time by 15%”.Tailor your resume to each job you apply for

. Be sure to highlight the skills and experience that are most relevant to the specific position.Proofread your resume carefully

. Make sure there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Plate Sensitizer Resume

- Prepare and sensitize light-sensitive printing plates for use in photolithography.

- Operate and maintain plate coating, developing, etching, and stripping equipment.

- Inspect plates for defects and ensure they meet quality standards.

- Troubleshoot and resolve issues related to the plate sensitization process.

- Follow safety protocols and maintain a clean and organized work area.

- Work closely with other members of the production team to ensure smooth and efficient operations.

- Contribute to continuous improvement initiatives and process optimization.

Frequently Asked Questions (FAQ’s) For Plate Sensitizer

What is the role of a Plate Sensitizer?

A Plate Sensitizer is responsible for preparing and sensitizing light-sensitive printing plates for use in photolithography. This involves coating, developing, etching, and stripping the plates to create the desired pattern.

What are the key skills required for a Plate Sensitizer?

The key skills required for a Plate Sensitizer include photolithography, coating, developing, etching, stripping, and inspection. They must also have a strong understanding of safety protocols and be able to work effectively in a team environment.

What is the work environment of a Plate Sensitizer?

Plate Sensitizers typically work in a cleanroom environment. They must wear protective clothing and follow safety protocols to minimize the risk of accidents.

What are the career opportunities for a Plate Sensitizer?

Plate Sensitizers can advance to supervisory or management positions. They can also move into other areas of the semiconductor industry, such as process engineering or quality control.

What is the salary range for a Plate Sensitizer?

The salary range for a Plate Sensitizer can vary depending on experience, location, and company size. According to Indeed, the average salary for a Plate Sensitizer in the United States is $55,000 per year.

What are the benefits of working as a Plate Sensitizer?

The benefits of working as a Plate Sensitizer can include competitive salary and benefits, opportunities for career advancement, and a chance to work in a high-tech industry.

What are the challenges of working as a Plate Sensitizer?

The challenges of working as a Plate Sensitizer can include working in a cleanroom environment, following safety protocols, and meeting tight deadlines.

How can I become a Plate Sensitizer?

To become a Plate Sensitizer, you typically need a bachelor’s degree in science, such as chemistry or physics. You also need experience in photolithography, coating, developing, etching, stripping, and inspection processes.