Are you a seasoned Plating Engineer seeking a new career path? Discover our professionally built Plating Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

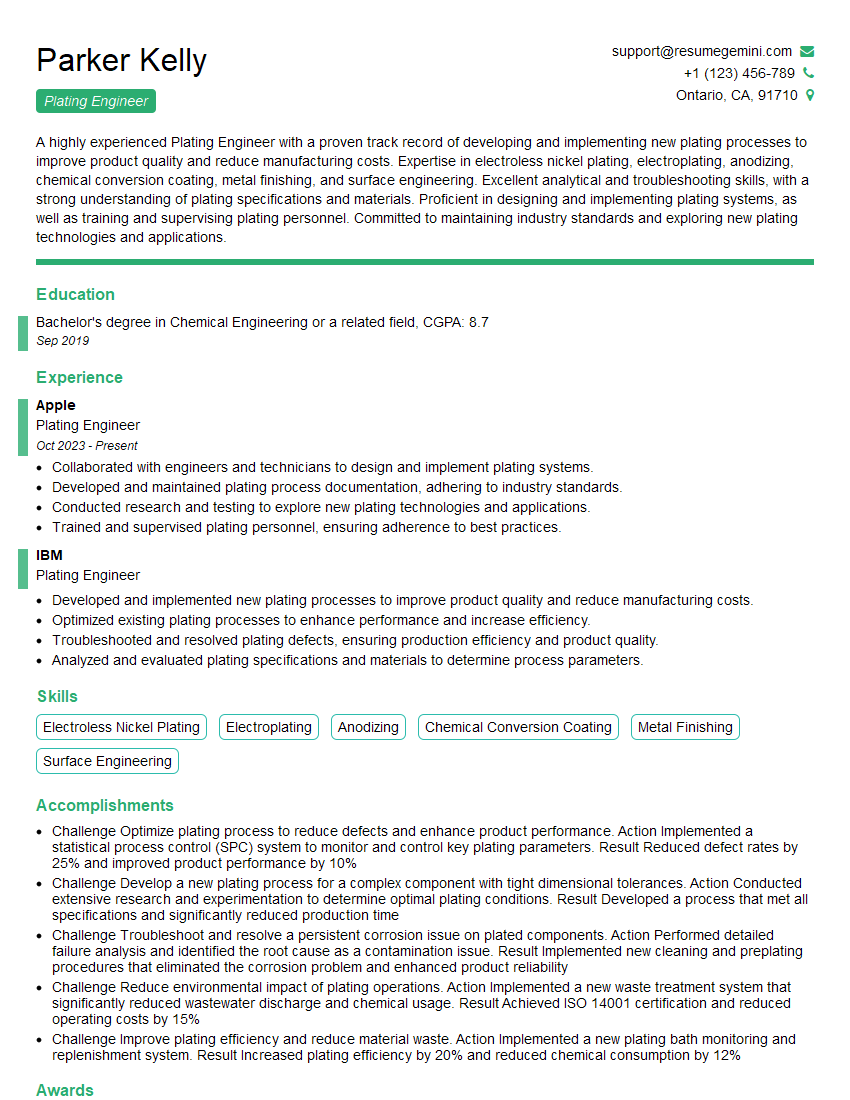

Parker Kelly

Plating Engineer

Summary

A highly experienced Plating Engineer with a proven track record of developing and implementing new plating processes to improve product quality and reduce manufacturing costs. Expertise in electroless nickel plating, electroplating, anodizing, chemical conversion coating, metal finishing, and surface engineering. Excellent analytical and troubleshooting skills, with a strong understanding of plating specifications and materials. Proficient in designing and implementing plating systems, as well as training and supervising plating personnel. Committed to maintaining industry standards and exploring new plating technologies and applications.

Education

Bachelor’s degree in Chemical Engineering or a related field

September 2019

Skills

- Electroless Nickel Plating

- Electroplating

- Anodizing

- Chemical Conversion Coating

- Metal Finishing

- Surface Engineering

Work Experience

Plating Engineer

- Collaborated with engineers and technicians to design and implement plating systems.

- Developed and maintained plating process documentation, adhering to industry standards.

- Conducted research and testing to explore new plating technologies and applications.

- Trained and supervised plating personnel, ensuring adherence to best practices.

Plating Engineer

- Developed and implemented new plating processes to improve product quality and reduce manufacturing costs.

- Optimized existing plating processes to enhance performance and increase efficiency.

- Troubleshooted and resolved plating defects, ensuring production efficiency and product quality.

- Analyzed and evaluated plating specifications and materials to determine process parameters.

Accomplishments

- Challenge Optimize plating process to reduce defects and enhance product performance. Action Implemented a statistical process control (SPC) system to monitor and control key plating parameters. Result Reduced defect rates by 25% and improved product performance by 10%

- Challenge Develop a new plating process for a complex component with tight dimensional tolerances. Action Conducted extensive research and experimentation to determine optimal plating conditions. Result Developed a process that met all specifications and significantly reduced production time

- Challenge Troubleshoot and resolve a persistent corrosion issue on plated components. Action Performed detailed failure analysis and identified the root cause as a contamination issue. Result Implemented new cleaning and preplating procedures that eliminated the corrosion problem and enhanced product reliability

- Challenge Reduce environmental impact of plating operations. Action Implemented a new waste treatment system that significantly reduced wastewater discharge and chemical usage. Result Achieved ISO 14001 certification and reduced operating costs by 15%

- Challenge Improve plating efficiency and reduce material waste. Action Implemented a new plating bath monitoring and replenishment system. Result Increased plating efficiency by 20% and reduced chemical consumption by 12%

Awards

- Received Plating Engineer of the Year award from the American Electroplaters and Surface Finishers Society (AESF)

- Recognized for excellence in plating technology and innovation by the National Association for Surface Finishing (NASF)

- Awarded a patent for developing a new electroplating process that significantly improved coating quality and efficiency

Certificates

- Certified Plating and Surface Finisher (CPFS)

- Certified Anodizer (CA)

- Certified Chemical Conversion Coating Applicator (CCCC)

- Certified Corrosion Tester (CCT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plating Engineer

- Highlight your experience in developing and implementing new plating processes.

- Quantify your accomplishments, providing specific examples of how you have improved product quality or reduced manufacturing costs.

- Demonstrate your expertise in a variety of plating techniques, including electroless nickel plating, electroplating, anodizing, chemical conversion coating, metal finishing, and surface engineering.

- Showcase your analytical and troubleshooting skills, and your ability to resolve plating defects.

- Emphasize your experience in training and supervising plating personnel.

Essential Experience Highlights for a Strong Plating Engineer Resume

- Develop and implement new plating processes to improve product quality and reduce manufacturing costs.

- Optimize existing plating processes to enhance performance and increase efficiency.

- Troubleshoot and resolve plating defects, ensuring production efficiency and product quality.

- Analyze and evaluate plating specifications and materials to determine process parameters.

- Collaborate with engineers and technicians to design and implement plating systems.

- Develop and maintain plating process documentation, adhering to industry standards.

- Conduct research and testing to explore new plating technologies and applications.

- Train and supervise plating personnel, ensuring adherence to best practices.

Frequently Asked Questions (FAQ’s) For Plating Engineer

What is the role of a Plating Engineer?

A Plating Engineer is responsible for developing, implementing, and optimizing plating processes to improve product quality and reduce manufacturing costs. They work closely with engineers and technicians to design and implement plating systems, and train and supervise plating personnel.

What are the key skills required for a Plating Engineer?

The key skills required for a Plating Engineer include expertise in electroless nickel plating, electroplating, anodizing, chemical conversion coating, metal finishing, and surface engineering. They should also have excellent analytical and troubleshooting skills, and a strong understanding of plating specifications and materials.

What are the career prospects for a Plating Engineer?

Plating Engineers are in high demand in a variety of industries, including automotive, aerospace, electronics, and medical devices. With experience, they can advance to management positions or specialize in a particular area of plating.

What is the average salary for a Plating Engineer?

The average salary for a Plating Engineer in the United States is around $75,000 per year. However, salaries can vary depending on experience, location, and industry.

What are the educational requirements for a Plating Engineer?

Most Plating Engineers have a bachelor’s degree in chemical engineering or a related field. However, some employers may also consider candidates with an associate’s degree or relevant experience.

What are the professional organizations for Plating Engineers?

The two main professional organizations for Plating Engineers are the American Electroplaters and Surface Finishers Society (AESF) and the Institute of Metal Finishing (IMF).

What are the certifications available for Plating Engineers?

The AESF offers a Certified Plating Engineer (CPE) certification, which demonstrates a high level of knowledge and experience in the field of plating.