Are you a seasoned Plating Foreman seeking a new career path? Discover our professionally built Plating Foreman Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

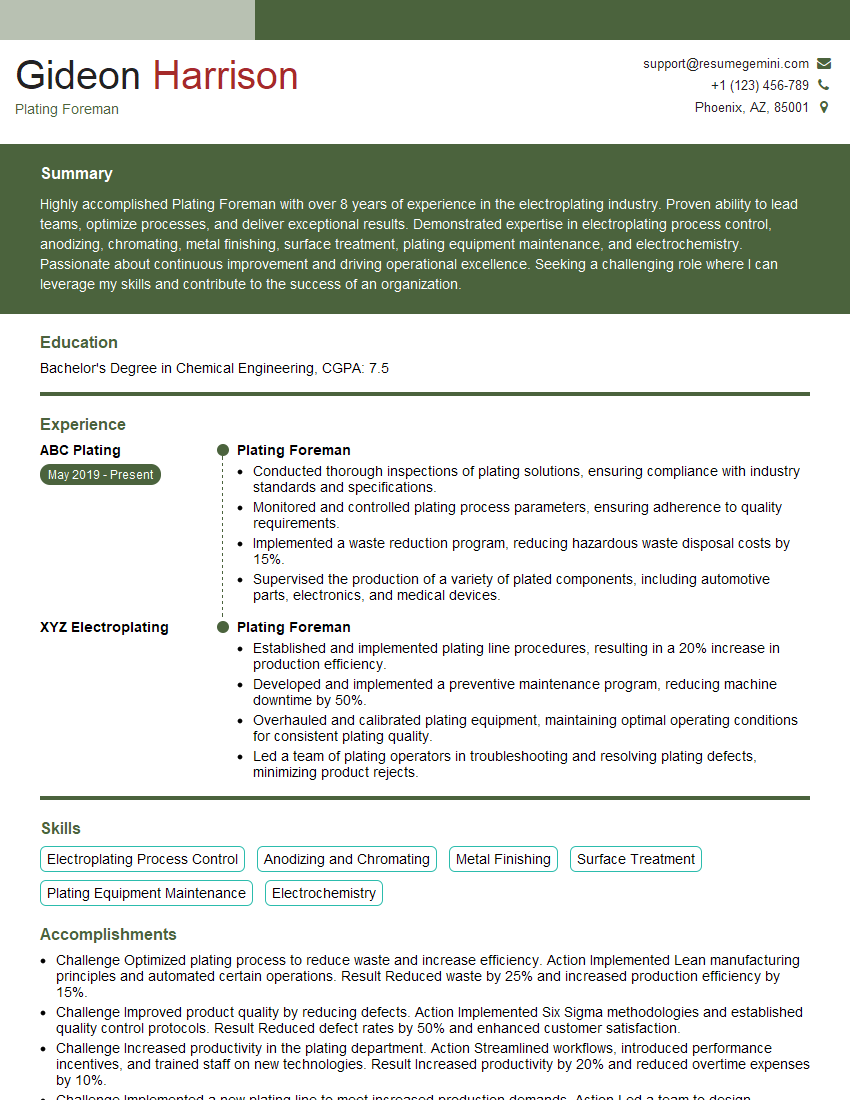

Gideon Harrison

Plating Foreman

Summary

Highly accomplished Plating Foreman with over 8 years of experience in the electroplating industry. Proven ability to lead teams, optimize processes, and deliver exceptional results. Demonstrated expertise in electroplating process control, anodizing, chromating, metal finishing, surface treatment, plating equipment maintenance, and electrochemistry. Passionate about continuous improvement and driving operational excellence. Seeking a challenging role where I can leverage my skills and contribute to the success of an organization.

Education

Bachelor’s Degree in Chemical Engineering

April 2015

Skills

- Electroplating Process Control

- Anodizing and Chromating

- Metal Finishing

- Surface Treatment

- Plating Equipment Maintenance

- Electrochemistry

Work Experience

Plating Foreman

- Conducted thorough inspections of plating solutions, ensuring compliance with industry standards and specifications.

- Monitored and controlled plating process parameters, ensuring adherence to quality requirements.

- Implemented a waste reduction program, reducing hazardous waste disposal costs by 15%.

- Supervised the production of a variety of plated components, including automotive parts, electronics, and medical devices.

Plating Foreman

- Established and implemented plating line procedures, resulting in a 20% increase in production efficiency.

- Developed and implemented a preventive maintenance program, reducing machine downtime by 50%.

- Overhauled and calibrated plating equipment, maintaining optimal operating conditions for consistent plating quality.

- Led a team of plating operators in troubleshooting and resolving plating defects, minimizing product rejects.

Accomplishments

- Challenge Optimized plating process to reduce waste and increase efficiency. Action Implemented Lean manufacturing principles and automated certain operations. Result Reduced waste by 25% and increased production efficiency by 15%.

- Challenge Improved product quality by reducing defects. Action Implemented Six Sigma methodologies and established quality control protocols. Result Reduced defect rates by 50% and enhanced customer satisfaction.

- Challenge Increased productivity in the plating department. Action Streamlined workflows, introduced performance incentives, and trained staff on new technologies. Result Increased productivity by 20% and reduced overtime expenses by 10%.

- Challenge Implemented a new plating line to meet increased production demands. Action Led a team to design, procure, and install the new line. Result Increased production capacity by 30% and reduced lead times by 20%.

- Challenge Ensured compliance with industry and environmental regulations. Action Established and implemented comprehensive compliance programs. Result Achieved and maintained all required certifications and standards.

Awards

- American Electroplaters Society (AES) Plating Foreman of the Year Award

- Society of Vacuum Coaters (SVC) Foreman Excellence Award

- National Association for Surface Finishing (NASF) Foreman Leadership Award

- Metal Finishing Magazine Plating Foreman of Distinction

Certificates

- Certified Plating Foreman (CPF)

- Certified Electroplater Finisher (CEF)

- Certified Quality Engineer (CQE)

- ISO 9001 Lead Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plating Foreman

- Highlight your expertise in electroplating process control and ability to optimize plating line efficiency.

- Showcase your experience in developing and implementing preventive maintenance programs to minimize downtime.

- Emphasize your leadership and team management skills, as well as your ability to train and motivate plating operators.

- Quantify your accomplishments with specific metrics, such as increased production efficiency, reduced downtime, and improved quality.

Essential Experience Highlights for a Strong Plating Foreman Resume

- Establish and implement plating line procedures to improve production efficiency and quality.

- Develop and execute preventive maintenance programs to minimize machine downtime and ensure optimal equipment performance.

- Overhaul and calibrate plating equipment to maintain consistent plating quality and meet industry standards.

- Lead and supervise a team of plating operators, providing guidance and training to ensure adherence to best practices.

- Conduct thorough inspections of plating solutions and monitor process parameters to ensure compliance with industry regulations.

- Implement waste reduction programs to minimize environmental impact and reduce operational costs.

- Supervise the production of a variety of plated components, including automotive parts, electronics, and medical devices.

Frequently Asked Questions (FAQ’s) For Plating Foreman

What are the key responsibilities of a Plating Foreman?

The primary responsibilities include establishing and implementing plating line procedures, developing preventive maintenance programs, overseeing equipment calibration, leading and supervising plating operators, conducting quality inspections, implementing waste reduction initiatives, and supervising the production of plated components.

What qualifications are required to become a Plating Foreman?

Typically, a Plating Foreman requires a Bachelor’s Degree in Chemical Engineering or a related field, along with several years of experience in the electroplating industry. Strong knowledge of electroplating processes, surface treatment techniques, and equipment maintenance is essential.

What are the career prospects for a Plating Foreman?

Plating Foremen with proven experience and expertise can advance to roles such as Plating Manager, Production Supervisor, or Quality Control Manager. They may also specialize in specific areas, such as automotive plating, electronics plating, or medical device plating.

What are the challenges faced by Plating Foremen?

Plating Foremen may encounter challenges related to maintaining consistent plating quality, optimizing production efficiency, minimizing waste and environmental impact, and ensuring adherence to industry regulations and standards.

What are the key skills required for a Plating Foreman?

Essential skills for a Plating Foreman include electroplating process control, anodizing and chromating, metal finishing, surface treatment, plating equipment maintenance, and electrochemistry.

What industries employ Plating Foremen?

Plating Foremen find employment in various industries, including automotive, electronics, aerospace, medical devices, and general manufacturing.

What is the average salary range for a Plating Foreman?

The salary range for Plating Foremen can vary depending on experience, location, and industry. According to Salary.com, the average salary range in the United States is between $60,000 and $90,000 per year.

What are the growth prospects for Plating Foremen?

The growth prospects for Plating Foremen are expected to be positive due to the increasing demand for plated components in various industries. Advancements in electroplating technologies and the need for skilled professionals to ensure quality and efficiency will drive job growth.