Are you a seasoned Plating Technician seeking a new career path? Discover our professionally built Plating Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

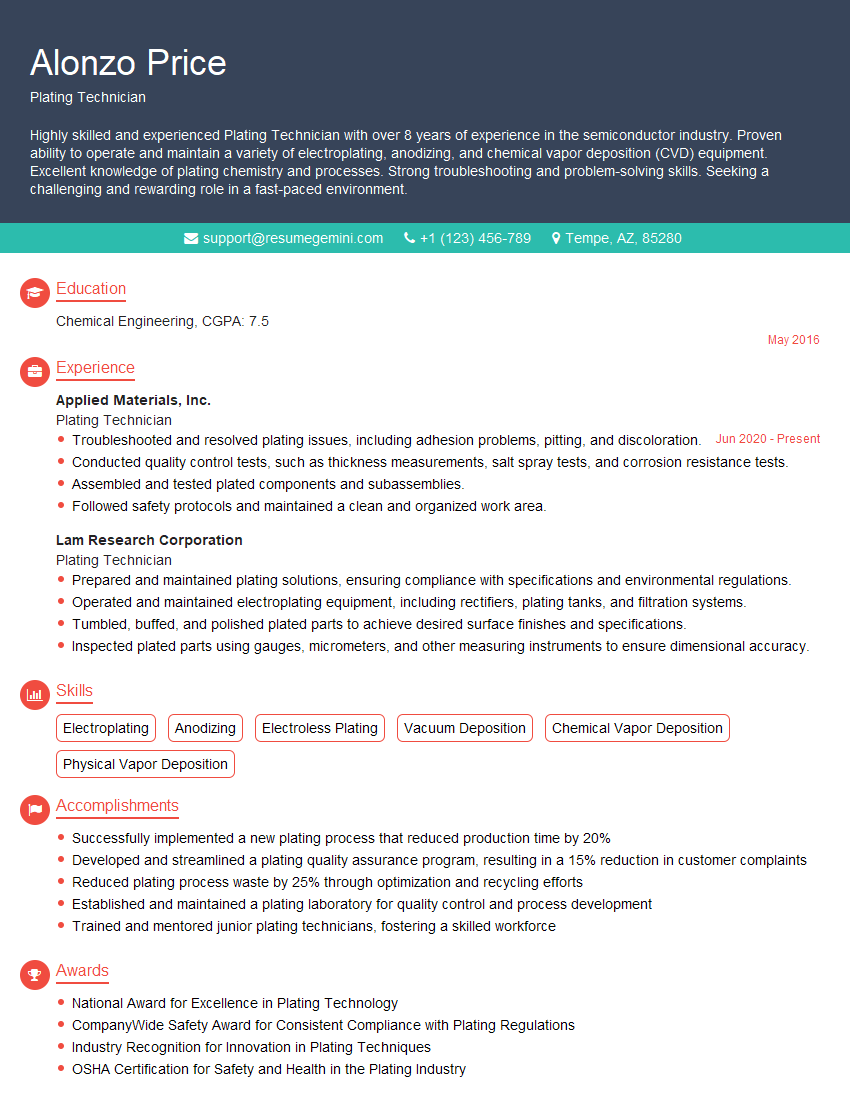

Alonzo Price

Plating Technician

Summary

Highly skilled and experienced Plating Technician with over 8 years of experience in the semiconductor industry. Proven ability to operate and maintain a variety of electroplating, anodizing, and chemical vapor deposition (CVD) equipment. Excellent knowledge of plating chemistry and processes. Strong troubleshooting and problem-solving skills. Seeking a challenging and rewarding role in a fast-paced environment.

Education

Chemical Engineering

May 2016

Skills

- Electroplating

- Anodizing

- Electroless Plating

- Vacuum Deposition

- Chemical Vapor Deposition

- Physical Vapor Deposition

Work Experience

Plating Technician

- Troubleshooted and resolved plating issues, including adhesion problems, pitting, and discoloration.

- Conducted quality control tests, such as thickness measurements, salt spray tests, and corrosion resistance tests.

- Assembled and tested plated components and subassemblies.

- Followed safety protocols and maintained a clean and organized work area.

Plating Technician

- Prepared and maintained plating solutions, ensuring compliance with specifications and environmental regulations.

- Operated and maintained electroplating equipment, including rectifiers, plating tanks, and filtration systems.

- Tumbled, buffed, and polished plated parts to achieve desired surface finishes and specifications.

- Inspected plated parts using gauges, micrometers, and other measuring instruments to ensure dimensional accuracy.

Accomplishments

- Successfully implemented a new plating process that reduced production time by 20%

- Developed and streamlined a plating quality assurance program, resulting in a 15% reduction in customer complaints

- Reduced plating process waste by 25% through optimization and recycling efforts

- Established and maintained a plating laboratory for quality control and process development

- Trained and mentored junior plating technicians, fostering a skilled workforce

Awards

- National Award for Excellence in Plating Technology

- CompanyWide Safety Award for Consistent Compliance with Plating Regulations

- Industry Recognition for Innovation in Plating Techniques

- OSHA Certification for Safety and Health in the Plating Industry

Certificates

- Certified Electroplater-Finisher (CEF)

- Certified Plating and Surface Finishing Technician (CPST)

- Certified Anodizer (CA)

- Certified Vacuum Coater (CVC)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plating Technician

- Highlight your skills and experience in the resume summary.

- Use keywords from the job description in your resume.

- Quantify your accomplishments whenever possible.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Plating Technician Resume

- Operated and maintained a variety of electroplating, anodizing, electroless plating, vacuum deposition, chemical vapor deposition, and physical vapor deposition equipment.

- Developed and implemented new plating processes and procedures.

- Troubleshot and resolved plating problems.

- Performed quality control inspections on plated parts.

- Maintained a clean and organized work area.

- Adhered to all safety regulations.

Frequently Asked Questions (FAQ’s) For Plating Technician

What is a Plating Technician?

A Plating Technician is responsible for the application of metallic and non-metallic coatings to various materials using electroplating, anodizing, electroless plating, vacuum deposition, chemical vapor deposition, and physical vapor deposition techniques.

What are the educational requirements for a Plating Technician?

Plating Technicians typically have a high school diploma or equivalent. Some employers may require a degree in chemistry, chemical engineering, or a related field.

What are the job duties of a Plating Technician?

Plating Technicians operate and maintain electroplating, anodizing, electroless plating, vacuum deposition, chemical vapor deposition, and physical vapor deposition equipment. They also develop and implement new plating processes and procedures, troubleshoot and resolve plating problems, perform quality control inspections on plated parts, maintain a clean and organized work area, and adhere to all safety regulations.

What are the skills required for a Plating Technician?

Plating Technicians should have strong knowledge of plating chemistry and processes, as well as excellent troubleshooting and problem-solving skills. They should also be able to operate and maintain a variety of electroplating, anodizing, electroless plating, vacuum deposition, chemical vapor deposition, and physical vapor deposition equipment.

What is the salary range for a Plating Technician?

The salary range for a Plating Technician varies depending on experience, location, and employer. According to Salary.com, the average salary for a Plating Technician in the United States is $25.50 per hour.

What is the job outlook for Plating Technicians?

The job outlook for Plating Technicians is expected to be good over the next few years. The demand for Plating Technicians is expected to increase as the manufacturing industry continues to grow.