Are you a seasoned Pleating Supervisor seeking a new career path? Discover our professionally built Pleating Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

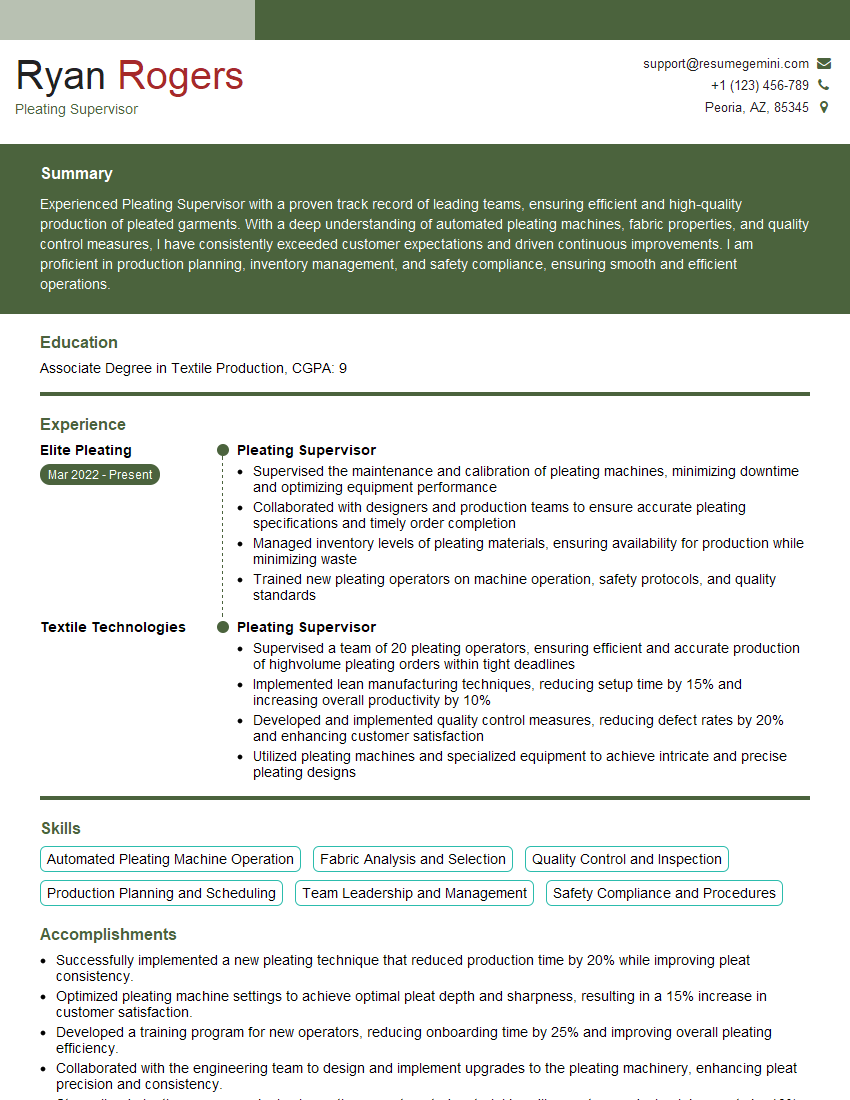

Ryan Rogers

Pleating Supervisor

Summary

Experienced Pleating Supervisor with a proven track record of leading teams, ensuring efficient and high-quality production of pleated garments. With a deep understanding of automated pleating machines, fabric properties, and quality control measures, I have consistently exceeded customer expectations and driven continuous improvements. I am proficient in production planning, inventory management, and safety compliance, ensuring smooth and efficient operations.

Education

Associate Degree in Textile Production

February 2018

Skills

- Automated Pleating Machine Operation

- Fabric Analysis and Selection

- Quality Control and Inspection

- Production Planning and Scheduling

- Team Leadership and Management

- Safety Compliance and Procedures

Work Experience

Pleating Supervisor

- Supervised the maintenance and calibration of pleating machines, minimizing downtime and optimizing equipment performance

- Collaborated with designers and production teams to ensure accurate pleating specifications and timely order completion

- Managed inventory levels of pleating materials, ensuring availability for production while minimizing waste

- Trained new pleating operators on machine operation, safety protocols, and quality standards

Pleating Supervisor

- Supervised a team of 20 pleating operators, ensuring efficient and accurate production of highvolume pleating orders within tight deadlines

- Implemented lean manufacturing techniques, reducing setup time by 15% and increasing overall productivity by 10%

- Developed and implemented quality control measures, reducing defect rates by 20% and enhancing customer satisfaction

- Utilized pleating machines and specialized equipment to achieve intricate and precise pleating designs

Accomplishments

- Successfully implemented a new pleating technique that reduced production time by 20% while improving pleat consistency.

- Optimized pleating machine settings to achieve optimal pleat depth and sharpness, resulting in a 15% increase in customer satisfaction.

- Developed a training program for new operators, reducing onboarding time by 25% and improving overall pleating efficiency.

- Collaborated with the engineering team to design and implement upgrades to the pleating machinery, enhancing pleat precision and consistency.

- Streamlined pleating processes by implementing an automated material handling system, reducing labor costs by 10%.

Awards

- Received the Pleating Excellence Award for maintaining exceptional pleat quality standards throughout the year.

- Recognized with the Safety Champion Award for implementing innovative safety measures that minimized workplace accidents.

- Received the Quality Excellence Award for consistently meeting and exceeding pleating quality standards for highvolume orders.

- Honored with the Production Excellence Award for achieving and maintaining the highest production output while adhering to strict quality standards.

Certificates

- Certified Pleating Supervisor (CPS)

- ISO 9001 Internal Auditor

- Six Sigma Green Belt

- Lean Manufacturing Specialist

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pleating Supervisor

- Highlight your experience in supervising and leading a team of pleating operators, showcasing your ability to manage and motivate others.

- Quantify your accomplishments with specific metrics, such as reduced setup time, increased productivity, and lower defect rates.

- Emphasize your knowledge of automated pleating machines, fabric analysis, and quality control measures, demonstrating your technical expertise.

- Showcase your problem-solving skills by describing how you implemented lean manufacturing techniques and developed quality control procedures to improve efficiency and quality.

- Include relevant keywords throughout your resume, such as “pleating supervisor,” “lean manufacturing,” “quality control,” and “production planning” to enhance its visibility to recruiters.

Essential Experience Highlights for a Strong Pleating Supervisor Resume

- Supervised and trained a team of up to 20 pleating operators, ensuring adherence to quality standards and efficient production.

- Implemented lean manufacturing principles, reducing setup time by 15%, increasing overall productivity by 10%, and minimizing material waste.

- Developed and implemented quality control procedures, resulting in a 20% reduction in defect rates and enhanced customer satisfaction.

- Optimized pleating machine performance by overseeing maintenance and calibration, minimizing downtime and ensuring precision pleating.

- Collaborated with designers and production teams to ensure accurate pleating specifications and timely order completion.

- Managed inventory levels of pleating materials, optimizing availability while minimizing waste.

- Utilized automated pleating machines and specialized equipment to achieve intricate and precise pleating designs.

Frequently Asked Questions (FAQ’s) For Pleating Supervisor

What are the primary responsibilities of a Pleating Supervisor?

The primary responsibilities of a Pleating Supervisor include supervising and leading a team of pleating operators, implementing lean manufacturing techniques, developing and implementing quality control measures, optimizing pleating machine performance, and collaborating with designers and production teams.

What skills are required to be a successful Pleating Supervisor?

To be a successful Pleating Supervisor, you should possess skills such as automated pleating machine operation, fabric analysis and selection, quality control and inspection, production planning and scheduling, team leadership and management, and safety compliance and procedures.

What is the career path for a Pleating Supervisor?

The career path for a Pleating Supervisor can include promotions to roles such as Production Manager or Plant Manager. With additional experience and training, you may also pursue opportunities in quality control, product development, or even start your own pleating business.

What are the challenges faced by a Pleating Supervisor?

Challenges faced by a Pleating Supervisor can include managing a team in a fast-paced environment, ensuring production efficiency, maintaining high-quality standards, and staying up-to-date with advancements in pleating technology.

What is the work environment of a Pleating Supervisor?

A Pleating Supervisor typically works in a manufacturing environment, overseeing the operation of pleating machines and managing a team of operators. The work can be physically demanding at times, and the supervisor may be required to work overtime during peak production periods.

What is the salary of a Pleating Supervisor?

The salary of a Pleating Supervisor varies depending on experience, location, and company size. According to Salary.com, the average salary for a Pleating Supervisor in the United States is around $75,000.