Are you a seasoned Plodding Machine Operator seeking a new career path? Discover our professionally built Plodding Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

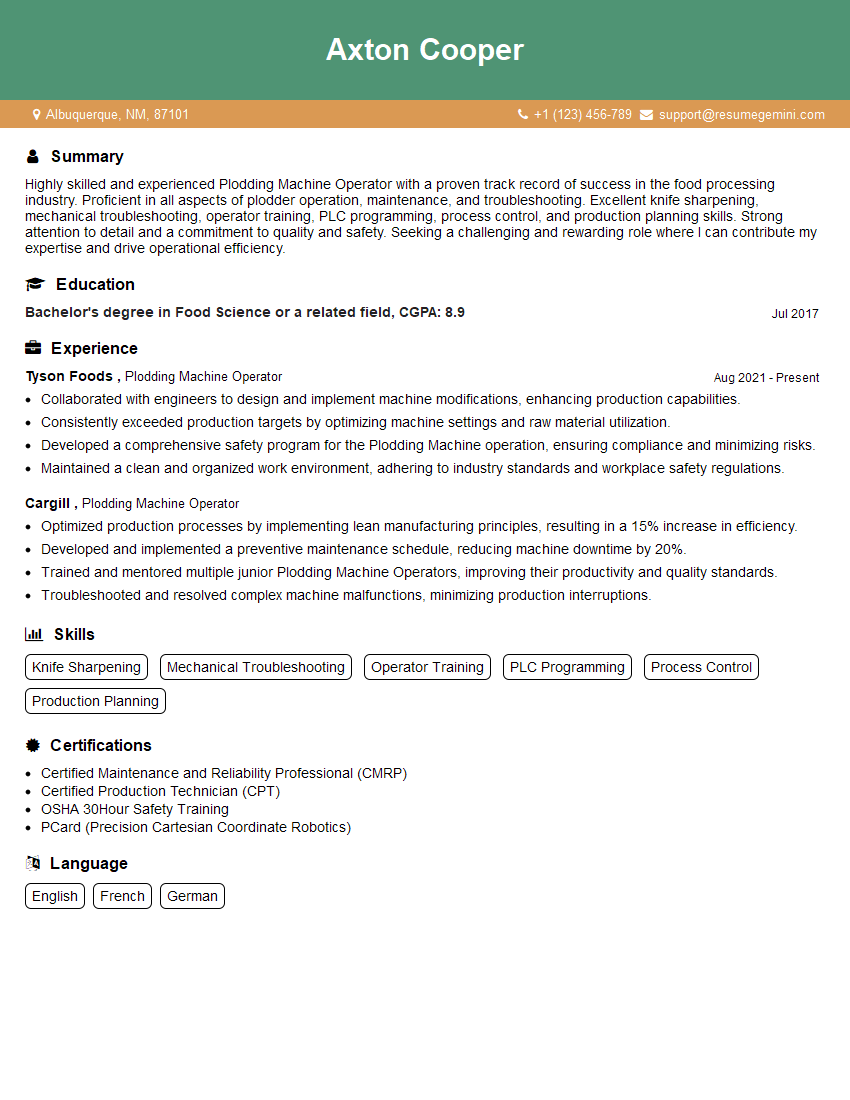

Axton Cooper

Plodding Machine Operator

Summary

Highly skilled and experienced Plodding Machine Operator with a proven track record of success in the food processing industry. Proficient in all aspects of plodder operation, maintenance, and troubleshooting. Excellent knife sharpening, mechanical troubleshooting, operator training, PLC programming, process control, and production planning skills. Strong attention to detail and a commitment to quality and safety. Seeking a challenging and rewarding role where I can contribute my expertise and drive operational efficiency.

Education

Bachelor’s degree in Food Science or a related field

July 2017

Skills

- Knife Sharpening

- Mechanical Troubleshooting

- Operator Training

- PLC Programming

- Process Control

- Production Planning

Work Experience

Plodding Machine Operator

- Collaborated with engineers to design and implement machine modifications, enhancing production capabilities.

- Consistently exceeded production targets by optimizing machine settings and raw material utilization.

- Developed a comprehensive safety program for the Plodding Machine operation, ensuring compliance and minimizing risks.

- Maintained a clean and organized work environment, adhering to industry standards and workplace safety regulations.

Plodding Machine Operator

- Optimized production processes by implementing lean manufacturing principles, resulting in a 15% increase in efficiency.

- Developed and implemented a preventive maintenance schedule, reducing machine downtime by 20%.

- Trained and mentored multiple junior Plodding Machine Operators, improving their productivity and quality standards.

- Troubleshooted and resolved complex machine malfunctions, minimizing production interruptions.

Certificates

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Production Technician (CPT)

- OSHA 30Hour Safety Training

- PCard (Precision Cartesian Coordinate Robotics)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plodding Machine Operator

- Highlight your experience and skills in operating, maintaining, and troubleshooting plodder machines.

- Quantify your accomplishments with specific metrics, such as reducing downtime or improving product quality.

- Demonstrate your knowledge of PLC programming and process control systems.

- Emphasize your commitment to safety and compliance with industry regulations.

- Proofread your resume carefully for any errors or inconsistencies.

Essential Experience Highlights for a Strong Plodding Machine Operator Resume

- Operate and monitor plodder machines to ensure optimal performance and product quality

- Sharpen and maintain knives to precise specifications to ensure efficient cutting and minimize waste

- Troubleshoot and resolve mechanical issues with plodder machines to prevent downtime and maintain production schedules

- Train and supervise operators on proper plodder operation and maintenance procedures

- Program and maintain PLCs to automate plodder processes and improve efficiency

- Monitor and control process parameters, such as temperature, pressure, and flow rates, to ensure product quality and safety

- Plan and schedule production runs to optimize equipment utilization and meet customer demand

Frequently Asked Questions (FAQ’s) For Plodding Machine Operator

What is a Plodding Machine Operator?

A Plodding Machine Operator is responsible for operating, maintaining, and troubleshooting plodder machines used in the food processing industry. Plodder machines are used to grind and mix meat, poultry, and other food products into a uniform consistency.

What are the key skills required for a Plodding Machine Operator?

Key skills for a Plodding Machine Operator include knife sharpening, mechanical troubleshooting, operator training, PLC programming, process control, and production planning.

What are the career prospects for a Plodding Machine Operator?

Plodding Machine Operators can advance to supervisory or management positions within the food processing industry. They may also specialize in a particular area, such as knife sharpening or PLC programming.

What is the average salary for a Plodding Machine Operator?

The average salary for a Plodding Machine Operator in the United States is around $40,000 per year.

What are the working conditions for a Plodding Machine Operator?

Plodding Machine Operators typically work in a food processing plant environment. They may be exposed to cold temperatures, noise, and other hazards. They must also be able to stand for long periods of time and lift heavy objects.

What are the educational requirements for a Plodding Machine Operator?

Most Plodding Machine Operators have a high school diploma or equivalent. Some employers may prefer candidates with a college degree in food science or a related field.

What are the certification requirements for a Plodding Machine Operator?

There are no specific certification requirements for a Plodding Machine Operator. However, some employers may prefer candidates with certification in food safety or other relevant areas.