Are you a seasoned Pneumatic Tester Mechanic seeking a new career path? Discover our professionally built Pneumatic Tester Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

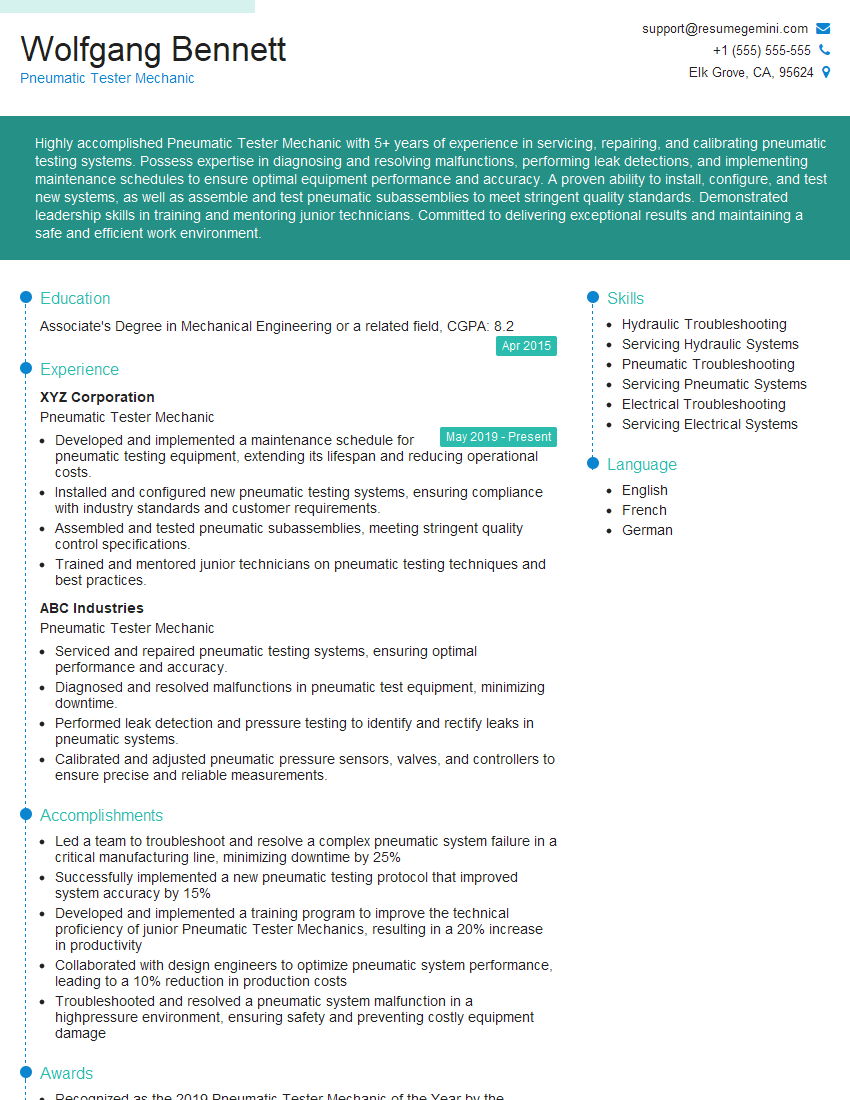

Wolfgang Bennett

Pneumatic Tester Mechanic

Summary

Highly accomplished Pneumatic Tester Mechanic with 5+ years of experience in servicing, repairing, and calibrating pneumatic testing systems. Possess expertise in diagnosing and resolving malfunctions, performing leak detections, and implementing maintenance schedules to ensure optimal equipment performance and accuracy. A proven ability to install, configure, and test new systems, as well as assemble and test pneumatic subassemblies to meet stringent quality standards. Demonstrated leadership skills in training and mentoring junior technicians. Committed to delivering exceptional results and maintaining a safe and efficient work environment.

Education

Associate’s Degree in Mechanical Engineering or a related field

April 2015

Skills

- Hydraulic Troubleshooting

- Servicing Hydraulic Systems

- Pneumatic Troubleshooting

- Servicing Pneumatic Systems

- Electrical Troubleshooting

- Servicing Electrical Systems

Work Experience

Pneumatic Tester Mechanic

- Developed and implemented a maintenance schedule for pneumatic testing equipment, extending its lifespan and reducing operational costs.

- Installed and configured new pneumatic testing systems, ensuring compliance with industry standards and customer requirements.

- Assembled and tested pneumatic subassemblies, meeting stringent quality control specifications.

- Trained and mentored junior technicians on pneumatic testing techniques and best practices.

Pneumatic Tester Mechanic

- Serviced and repaired pneumatic testing systems, ensuring optimal performance and accuracy.

- Diagnosed and resolved malfunctions in pneumatic test equipment, minimizing downtime.

- Performed leak detection and pressure testing to identify and rectify leaks in pneumatic systems.

- Calibrated and adjusted pneumatic pressure sensors, valves, and controllers to ensure precise and reliable measurements.

Accomplishments

- Led a team to troubleshoot and resolve a complex pneumatic system failure in a critical manufacturing line, minimizing downtime by 25%

- Successfully implemented a new pneumatic testing protocol that improved system accuracy by 15%

- Developed and implemented a training program to improve the technical proficiency of junior Pneumatic Tester Mechanics, resulting in a 20% increase in productivity

- Collaborated with design engineers to optimize pneumatic system performance, leading to a 10% reduction in production costs

- Troubleshooted and resolved a pneumatic system malfunction in a highpressure environment, ensuring safety and preventing costly equipment damage

Awards

- Recognized as the 2019 Pneumatic Tester Mechanic of the Year by the American Society of Mechanical Engineers

- Received a companywide award for innovative contributions to pneumatic testing practices

- Recognized for exceptional customer service in providing technical support to clients

- Recognized for contributions to the advancement of pneumatic testing technology

Certificates

- Compressed Air and Gas Institute (CAGI) Air System Inspector Certification

- Certified Maintenance and Reliability Technician (CMRT)

- Society of Automotive Engineers (SAE) Certified Fluid Power Specialist

- Occupational Safety and Health Administration (OSHA) Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pneumatic Tester Mechanic

- Quantify your accomplishments using specific metrics and data whenever possible.

- Highlight your skills in troubleshooting and problem-solving, as these are crucial for Pneumatic Tester Mechanics.

- Showcase your experience in servicing and repairing various types of pneumatic testing equipment.

- Emphasize your ability to work independently and as part of a team.

- Consider including certifications or specialized training in pneumatic testing to enhance your credibility.

Essential Experience Highlights for a Strong Pneumatic Tester Mechanic Resume

- Diagnose and resolve malfunctions in pneumatic test equipment, reducing downtime and ensuring optimal performance.

- Perform leak detection and pressure testing to identify and rectify leaks in pneumatic systems.

- Calibrate and adjust pneumatic pressure sensors, valves, and controllers to achieve precise and reliable measurements.

- Develop and implement maintenance schedules for pneumatic testing equipment, extending its lifespan and minimizing operational costs.

- Install and configure new pneumatic testing systems, ensuring compliance with industry standards and customer requirements.

- Assemble and test pneumatic subassemblies, adhering to stringent quality control specifications.

- Train and mentor junior technicians on pneumatic testing techniques and best practices.

Frequently Asked Questions (FAQ’s) For Pneumatic Tester Mechanic

What are the key skills required for a Pneumatic Tester Mechanic?

Pneumatic Tester Mechanics should possess a strong understanding of pneumatic systems, including principles of operation, troubleshooting techniques, and safety protocols. They should be proficient in using diagnostic and testing equipment, and have a keen eye for detail and precision.

What are the typical responsibilities of a Pneumatic Tester Mechanic?

Pneumatic Tester Mechanics are responsible for maintaining, repairing, and calibrating pneumatic test equipment, ensuring accurate and reliable measurements. They diagnose and resolve malfunctions, perform leak detection and pressure testing, and develop maintenance schedules to extend equipment lifespan and minimize downtime.

What are the career advancement opportunities for a Pneumatic Tester Mechanic?

With experience and additional training, Pneumatic Tester Mechanics can advance to roles such as Lead Mechanic, Supervisor, or Quality Control Inspector. They may also specialize in specific areas of pneumatic testing, such as aerospace or automotive.

What industries employ Pneumatic Tester Mechanics?

Pneumatic Tester Mechanics are employed in various industries that utilize pneumatic systems, including manufacturing, automotive, aerospace, and oil and gas.

What is the average salary for a Pneumatic Tester Mechanic?

The average salary for a Pneumatic Tester Mechanic can vary depending on experience, location, and industry. According to Indeed, the average salary in the United States is around $60,000 per year.

What are the educational requirements for a Pneumatic Tester Mechanic?

While formal education requirements may vary, most employers prefer candidates with an Associate’s Degree in Mechanical Engineering or a related field.