Are you a seasoned Polymerization Kettle Operator seeking a new career path? Discover our professionally built Polymerization Kettle Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

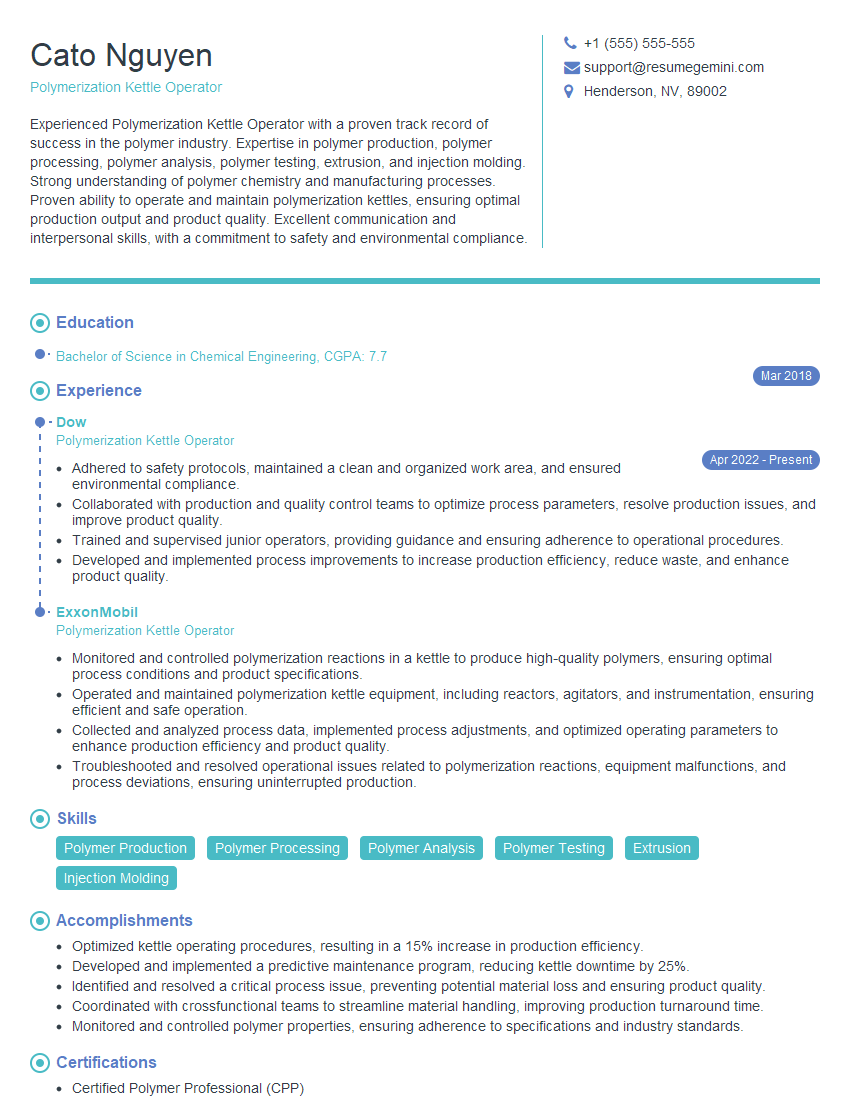

Cato Nguyen

Polymerization Kettle Operator

Summary

Experienced Polymerization Kettle Operator with a proven track record of success in the polymer industry. Expertise in polymer production, polymer processing, polymer analysis, polymer testing, extrusion, and injection molding. Strong understanding of polymer chemistry and manufacturing processes. Proven ability to operate and maintain polymerization kettles, ensuring optimal production output and product quality. Excellent communication and interpersonal skills, with a commitment to safety and environmental compliance.

Education

Bachelor of Science in Chemical Engineering

March 2018

Skills

- Polymer Production

- Polymer Processing

- Polymer Analysis

- Polymer Testing

- Extrusion

- Injection Molding

Work Experience

Polymerization Kettle Operator

- Adhered to safety protocols, maintained a clean and organized work area, and ensured environmental compliance.

- Collaborated with production and quality control teams to optimize process parameters, resolve production issues, and improve product quality.

- Trained and supervised junior operators, providing guidance and ensuring adherence to operational procedures.

- Developed and implemented process improvements to increase production efficiency, reduce waste, and enhance product quality.

Polymerization Kettle Operator

- Monitored and controlled polymerization reactions in a kettle to produce high-quality polymers, ensuring optimal process conditions and product specifications.

- Operated and maintained polymerization kettle equipment, including reactors, agitators, and instrumentation, ensuring efficient and safe operation.

- Collected and analyzed process data, implemented process adjustments, and optimized operating parameters to enhance production efficiency and product quality.

- Troubleshooted and resolved operational issues related to polymerization reactions, equipment malfunctions, and process deviations, ensuring uninterrupted production.

Accomplishments

- Optimized kettle operating procedures, resulting in a 15% increase in production efficiency.

- Developed and implemented a predictive maintenance program, reducing kettle downtime by 25%.

- Identified and resolved a critical process issue, preventing potential material loss and ensuring product quality.

- Coordinated with crossfunctional teams to streamline material handling, improving production turnaround time.

- Monitored and controlled polymer properties, ensuring adherence to specifications and industry standards.

Certificates

- Certified Polymer Professional (CPP)

- Polymer Processing Technician (PPT)

- Society of Plastics Engineers (SPE) Membership

- American Chemical Society (ACS) Membership

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Polymerization Kettle Operator

- Highlight your experience and skills in polymer production and processing.

- Quantify your accomplishments with specific metrics whenever possible.

- Emphasize your understanding of polymer chemistry and manufacturing processes.

- Demonstrate your commitment to safety and environmental compliance.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Polymerization Kettle Operator Resume

- Operate and monitor polymerization kettles to produce polymers according to specifications.

- Control process variables such as temperature, pressure, and flow rate to optimize production efficiency.

- Conduct quality control tests on polymers to ensure they meet customer requirements.

- Troubleshoot and resolve process problems to minimize downtime and maintain production schedules.

- Maintain and clean polymerization kettles and associated equipment to ensure optimal performance.

- Adhere to safety regulations and environmental standards to ensure a safe and compliant work environment.

- Work effectively as part of a team to achieve production goals.

- Stay updated on the latest polymer technology and manufacturing techniques.

Frequently Asked Questions (FAQ’s) For Polymerization Kettle Operator

What is the role of a Polymerization Kettle Operator?

A Polymerization Kettle Operator is responsible for operating and monitoring polymerization kettles to produce polymers according to specifications. They control process variables, conduct quality control tests, troubleshoot problems, and maintain equipment to ensure optimal production output and product quality.

What skills are required to be a Polymerization Kettle Operator?

Polymerization Kettle Operators typically need a Bachelor of Science in Chemical Engineering and experience in polymer production, polymer processing, polymer analysis, polymer testing, extrusion, and injection molding. They should also have a strong understanding of polymer chemistry and manufacturing processes, as well as excellent communication and interpersonal skills.

What is the work environment of a Polymerization Kettle Operator?

Polymerization Kettle Operators typically work in a manufacturing environment, operating polymerization kettles and associated equipment. They may also work in a laboratory setting, conducting quality control tests on polymers. They must be able to work independently and as part of a team, and must be able to follow safety regulations and environmental standards.

What is the salary range for a Polymerization Kettle Operator?

The salary range for a Polymerization Kettle Operator can vary depending on their experience, skills, and location. According to Salary.com, the average salary for a Polymerization Kettle Operator in the United States is $65,000 per year.

What is the job outlook for a Polymerization Kettle Operator?

The job outlook for a Polymerization Kettle Operator is expected to be good over the next few years. The increased demand for polymers in various industries is expected to drive growth in this field.

What are the advancement opportunities for a Polymerization Kettle Operator?

Polymerization Kettle Operators with experience and skills can advance to positions such as Polymer Production Supervisor, Polymer Process Engineer, or Quality Control Manager.

What is the difference between a Polymerization Kettle Operator and a Polymer Process Engineer?

A Polymerization Kettle Operator is responsible for operating and monitoring polymerization kettles to produce polymers according to specifications. A Polymer Process Engineer is responsible for designing and optimizing polymer manufacturing processes.

What is the difference between a Polymerization Kettle Operator and a Quality Control Technician?

A Polymerization Kettle Operator is responsible for operating and monitoring polymerization kettles to produce polymers according to specifications. A Quality Control Technician is responsible for conducting tests to ensure that polymers meet customer requirements.