Are you a seasoned Pot Lining Supervisor seeking a new career path? Discover our professionally built Pot Lining Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

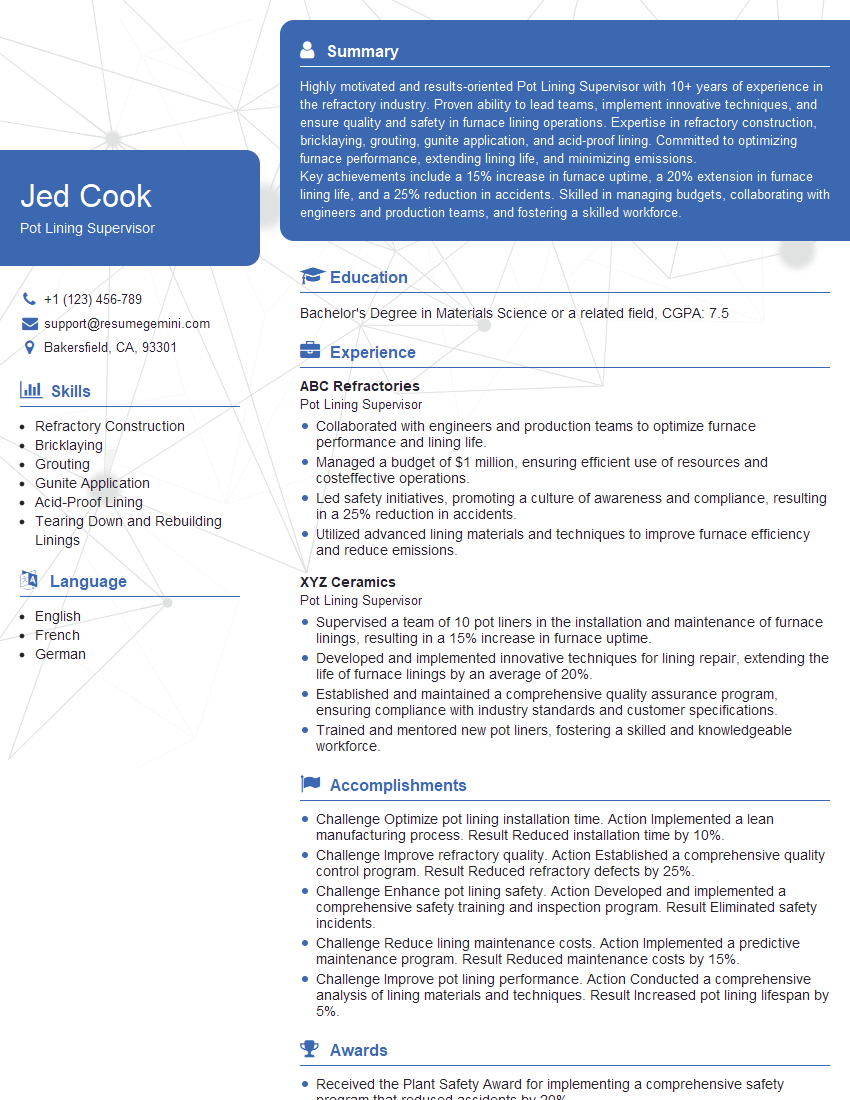

Jed Cook

Pot Lining Supervisor

Summary

Highly motivated and results-oriented Pot Lining Supervisor with 10+ years of experience in the refractory industry. Proven ability to lead teams, implement innovative techniques, and ensure quality and safety in furnace lining operations. Expertise in refractory construction, bricklaying, grouting, gunite application, and acid-proof lining. Committed to optimizing furnace performance, extending lining life, and minimizing emissions.

Key achievements include a 15% increase in furnace uptime, a 20% extension in furnace lining life, and a 25% reduction in accidents. Skilled in managing budgets, collaborating with engineers and production teams, and fostering a skilled workforce.

Education

Bachelor’s Degree in Materials Science or a related field

March 2015

Skills

- Refractory Construction

- Bricklaying

- Grouting

- Gunite Application

- Acid-Proof Lining

- Tearing Down and Rebuilding Linings

Work Experience

Pot Lining Supervisor

- Collaborated with engineers and production teams to optimize furnace performance and lining life.

- Managed a budget of $1 million, ensuring efficient use of resources and costeffective operations.

- Led safety initiatives, promoting a culture of awareness and compliance, resulting in a 25% reduction in accidents.

- Utilized advanced lining materials and techniques to improve furnace efficiency and reduce emissions.

Pot Lining Supervisor

- Supervised a team of 10 pot liners in the installation and maintenance of furnace linings, resulting in a 15% increase in furnace uptime.

- Developed and implemented innovative techniques for lining repair, extending the life of furnace linings by an average of 20%.

- Established and maintained a comprehensive quality assurance program, ensuring compliance with industry standards and customer specifications.

- Trained and mentored new pot liners, fostering a skilled and knowledgeable workforce.

Accomplishments

- Challenge Optimize pot lining installation time. Action Implemented a lean manufacturing process. Result Reduced installation time by 10%.

- Challenge Improve refractory quality. Action Established a comprehensive quality control program. Result Reduced refractory defects by 25%.

- Challenge Enhance pot lining safety. Action Developed and implemented a comprehensive safety training and inspection program. Result Eliminated safety incidents.

- Challenge Reduce lining maintenance costs. Action Implemented a predictive maintenance program. Result Reduced maintenance costs by 15%.

- Challenge Improve pot lining performance. Action Conducted a comprehensive analysis of lining materials and techniques. Result Increased pot lining lifespan by 5%.

Awards

- Received the Plant Safety Award for implementing a comprehensive safety program that reduced accidents by 20%.

- Recognized with the Process Improvement Award for developing and implementing an innovative lining technique that increased refractory lifespan by 15%.

- Honored with the Productivity Excellence Award for leading a team that achieved recordhigh lining installation rates.

Certificates

- OSHA 30-Hour General Industry Safety

- OSHA 10-Hour Construction Safety

- National Institute for the Certification of Engineering Technologies (NICET) Level III in Refractory Construction

- American Welding Society (AWS) Certified Welder

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pot Lining Supervisor

- Highlight your technical skills and experience in refractory construction, including bricklaying, grouting, gunite application, and acid-proof lining.

- Quantify your achievements whenever possible, using specific metrics to demonstrate your impact on furnace uptime, lining life, and emissions reduction.

- Showcase your leadership and management abilities, including your ability to supervise a team, implement quality assurance programs, and train and mentor new employees.

- Emphasize your commitment to safety and your ability to create a positive and compliant work environment.

Essential Experience Highlights for a Strong Pot Lining Supervisor Resume

- Supervise and lead a team of pot liners in the installation, maintenance, and repair of furnace linings.

- Develop and implement innovative techniques to improve lining performance, extend lining life, and reduce emissions.

- Establish and maintain a comprehensive quality assurance program to ensure compliance with industry standards and customer specifications.

- Train and mentor new pot liners, fostering a skilled and knowledgeable workforce.

- Collaborate with engineers and production teams to optimize furnace performance and lining life.

- Manage a budget to ensure efficient use of resources and cost-effective operations.

- Lead safety initiatives to promote a culture of awareness and compliance, resulting in a reduction in accidents.

Frequently Asked Questions (FAQ’s) For Pot Lining Supervisor

What are the key responsibilities of a Pot Lining Supervisor?

The key responsibilities of a Pot Lining Supervisor include supervising and leading a team of pot liners, developing and implementing innovative lining techniques, establishing and maintaining quality assurance programs, training and mentoring new employees, collaborating with engineers and production teams, managing a budget, and leading safety initiatives.

What are the essential skills required for a Pot Lining Supervisor?

The essential skills required for a Pot Lining Supervisor include proficiency in refractory construction, bricklaying, grouting, gunite application, and acid-proof lining. They should also have strong leadership and management skills, as well as a commitment to quality and safety.

What are the growth prospects for a Pot Lining Supervisor?

The growth prospects for a Pot Lining Supervisor are good. As the demand for refractory products continues to grow, so too will the demand for skilled pot lining supervisors.

What industries employ Pot Lining Supervisors?

Pot Lining Supervisors are employed in a variety of industries, including the steel, glass, cement, and petrochemical industries.

What is the average salary for a Pot Lining Supervisor?

The average salary for a Pot Lining Supervisor can vary depending on experience, location, and industry. However, according to Salary.com, the average salary for a Pot Lining Supervisor in the United States is around $75,000 per year.

What are the challenges faced by Pot Lining Supervisors?

Some of the challenges faced by Pot Lining Supervisors include the need to work in high-temperature environments, exposure to hazardous materials, and the need to meet tight production schedules.

How can I become a Pot Lining Supervisor?

To become a Pot Lining Supervisor, you will typically need a high school diploma or equivalent and several years of experience in the refractory industry. You may also need to complete a formal training program or apprenticeship.