Are you a seasoned Potter seeking a new career path? Discover our professionally built Potter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

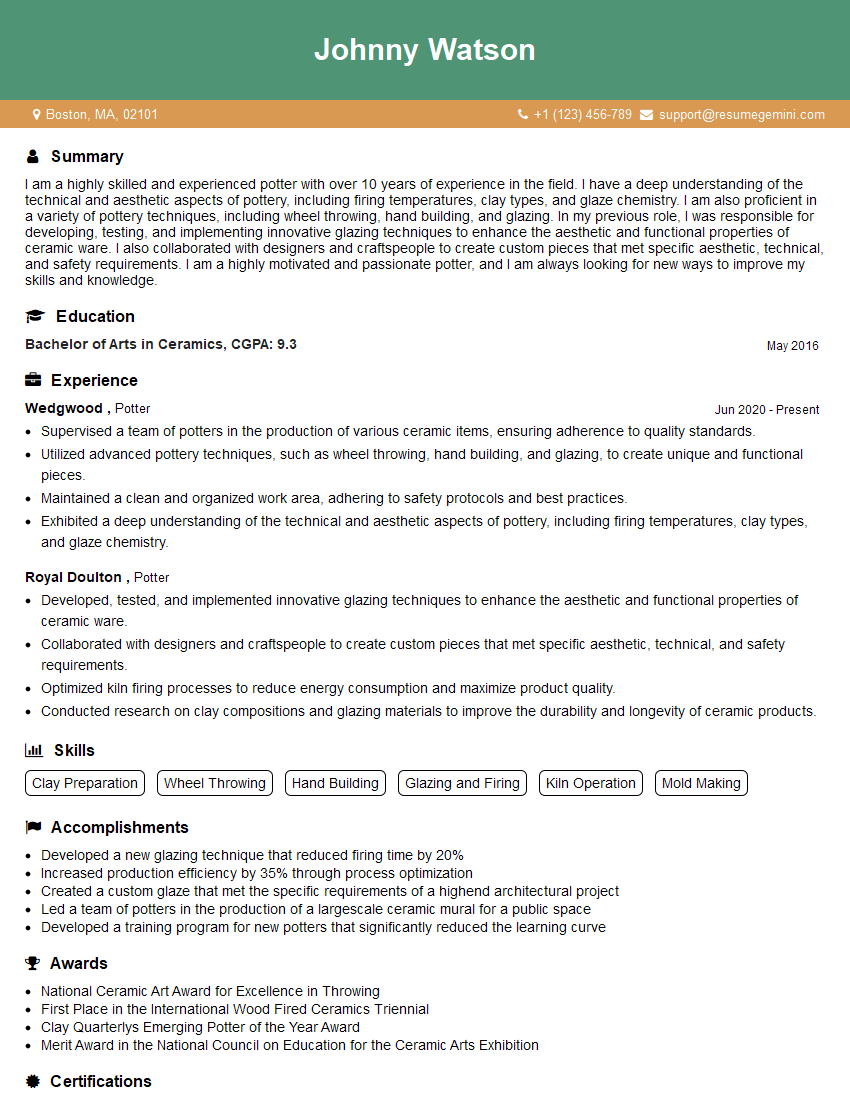

Johnny Watson

Potter

Summary

I am a highly skilled and experienced potter with over 10 years of experience in the field. I have a deep understanding of the technical and aesthetic aspects of pottery, including firing temperatures, clay types, and glaze chemistry. I am also proficient in a variety of pottery techniques, including wheel throwing, hand building, and glazing. In my previous role, I was responsible for developing, testing, and implementing innovative glazing techniques to enhance the aesthetic and functional properties of ceramic ware. I also collaborated with designers and craftspeople to create custom pieces that met specific aesthetic, technical, and safety requirements. I am a highly motivated and passionate potter, and I am always looking for new ways to improve my skills and knowledge.

Education

Bachelor of Arts in Ceramics

May 2016

Skills

- Clay Preparation

- Wheel Throwing

- Hand Building

- Glazing and Firing

- Kiln Operation

- Mold Making

Work Experience

Potter

- Supervised a team of potters in the production of various ceramic items, ensuring adherence to quality standards.

- Utilized advanced pottery techniques, such as wheel throwing, hand building, and glazing, to create unique and functional pieces.

- Maintained a clean and organized work area, adhering to safety protocols and best practices.

- Exhibited a deep understanding of the technical and aesthetic aspects of pottery, including firing temperatures, clay types, and glaze chemistry.

Potter

- Developed, tested, and implemented innovative glazing techniques to enhance the aesthetic and functional properties of ceramic ware.

- Collaborated with designers and craftspeople to create custom pieces that met specific aesthetic, technical, and safety requirements.

- Optimized kiln firing processes to reduce energy consumption and maximize product quality.

- Conducted research on clay compositions and glazing materials to improve the durability and longevity of ceramic products.

Accomplishments

- Developed a new glazing technique that reduced firing time by 20%

- Increased production efficiency by 35% through process optimization

- Created a custom glaze that met the specific requirements of a highend architectural project

- Led a team of potters in the production of a largescale ceramic mural for a public space

- Developed a training program for new potters that significantly reduced the learning curve

Awards

- National Ceramic Art Award for Excellence in Throwing

- First Place in the International Wood Fired Ceramics Triennial

- Clay Quarterlys Emerging Potter of the Year Award

- Merit Award in the National Council on Education for the Ceramic Arts Exhibition

Certificates

- NCECA Member

- American Ceramic Society Member

- Kiln Operator Certification

- CPR and First Aid Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Potter

- Use strong action verbs to describe your experience

- Quantify your accomplishments whenever possible

- Tailor your resume to each specific job you apply for

- Proofread your resume carefully before submitting it

Essential Experience Highlights for a Strong Potter Resume

- Developing, testing, and implementing innovative glazing techniques to enhance the aesthetic and functional properties of ceramic ware

- Collaborating with designers and craftspeople to create custom pieces that met specific aesthetic, technical, and safety requirements

- Optimizing kiln firing processes to reduce energy consumption and maximize product quality

- Conducting research on clay compositions and glazing materials to improve the durability and longevity of ceramic products

- Supervising a team of potters in the production of various ceramic items, ensuring adherence to quality standards

- Utilizing advanced pottery techniques, such as wheel throwing, hand building, and glazing, to create unique and functional pieces

- Maintaining a clean and organized work area, adhering to safety protocols and best practices

Frequently Asked Questions (FAQ’s) For Potter

How do I get started as a potter?

There are many ways to get started as a potter. You can take classes at a local community college or art center, or you can apprentice with an experienced potter. There are also many online resources and books available to help you learn the basics of pottery.

What are the different types of pottery?

There are many different types of pottery, including earthenware, stoneware, and porcelain. Earthenware is the most common type of pottery and is made from clay that is fired at a low temperature. Stoneware is a type of pottery that is made from clay that is fired at a higher temperature. Porcelain is a type of pottery that is made from clay that is fired at a very high temperature.

What are the different techniques used in pottery?

There are many different techniques used in pottery, including wheel throwing, hand building, and glazing. Wheel throwing is a technique in which a potter uses a spinning wheel to create a piece of pottery. Hand building is a technique in which a potter creates a piece of pottery by hand, without using a wheel. Glazing is a technique in which a potter applies a liquid to a piece of pottery that is then fired in a kiln.

What are the different types of kilns?

There are many different types of kilns, including electric kilns, gas kilns, and wood-fired kilns. Electric kilns are the most common type of kiln and are used to fire pottery at a variety of temperatures. Gas kilns are used to fire pottery at high temperatures and are often used to create stoneware and porcelain. Wood-fired kilns are used to fire pottery at very high temperatures and are often used to create unique and artistic pieces.

What is the future of pottery?

The future of pottery is bright. There is a growing interest in handmade pottery, and many potters are finding success selling their work online and at craft fairs. There are also many opportunities for potters to teach classes and workshops.