Are you a seasoned Powder Cutting Operator seeking a new career path? Discover our professionally built Powder Cutting Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

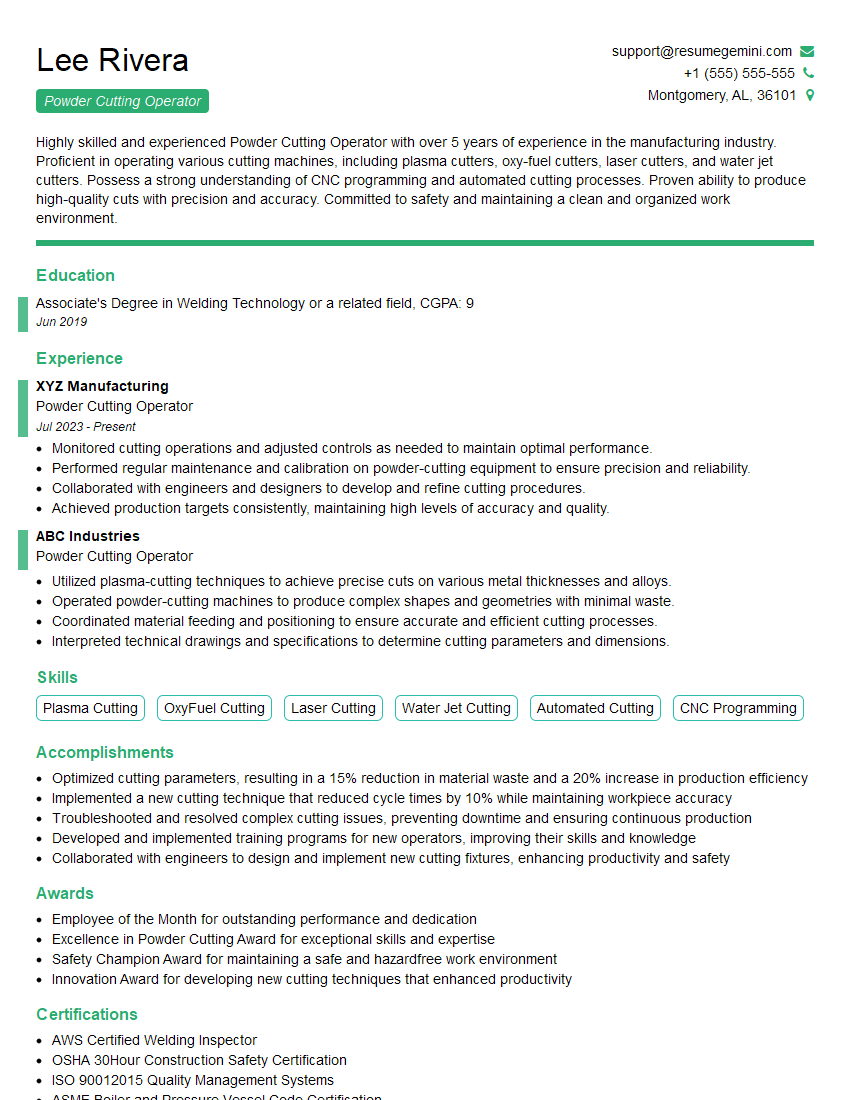

Lee Rivera

Powder Cutting Operator

Summary

Highly skilled and experienced Powder Cutting Operator with over 5 years of experience in the manufacturing industry. Proficient in operating various cutting machines, including plasma cutters, oxy-fuel cutters, laser cutters, and water jet cutters. Possess a strong understanding of CNC programming and automated cutting processes. Proven ability to produce high-quality cuts with precision and accuracy. Committed to safety and maintaining a clean and organized work environment.

Education

Associate’s Degree in Welding Technology or a related field

June 2019

Skills

- Plasma Cutting

- OxyFuel Cutting

- Laser Cutting

- Water Jet Cutting

- Automated Cutting

- CNC Programming

Work Experience

Powder Cutting Operator

- Monitored cutting operations and adjusted controls as needed to maintain optimal performance.

- Performed regular maintenance and calibration on powder-cutting equipment to ensure precision and reliability.

- Collaborated with engineers and designers to develop and refine cutting procedures.

- Achieved production targets consistently, maintaining high levels of accuracy and quality.

Powder Cutting Operator

- Utilized plasma-cutting techniques to achieve precise cuts on various metal thicknesses and alloys.

- Operated powder-cutting machines to produce complex shapes and geometries with minimal waste.

- Coordinated material feeding and positioning to ensure accurate and efficient cutting processes.

- Interpreted technical drawings and specifications to determine cutting parameters and dimensions.

Accomplishments

- Optimized cutting parameters, resulting in a 15% reduction in material waste and a 20% increase in production efficiency

- Implemented a new cutting technique that reduced cycle times by 10% while maintaining workpiece accuracy

- Troubleshooted and resolved complex cutting issues, preventing downtime and ensuring continuous production

- Developed and implemented training programs for new operators, improving their skills and knowledge

- Collaborated with engineers to design and implement new cutting fixtures, enhancing productivity and safety

Awards

- Employee of the Month for outstanding performance and dedication

- Excellence in Powder Cutting Award for exceptional skills and expertise

- Safety Champion Award for maintaining a safe and hazardfree work environment

- Innovation Award for developing new cutting techniques that enhanced productivity

Certificates

- AWS Certified Welding Inspector

- OSHA 30Hour Construction Safety Certification

- ISO 90012015 Quality Management Systems

- ASME Boiler and Pressure Vessel Code Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Powder Cutting Operator

- Highlight your experience with different types of cutting machines, including plasma cutters, oxy-fuel cutters, laser cutters, and water jet cutters.

- Showcase your proficiency in CNC programming and automated cutting processes.

- Emphasize your commitment to safety and your ability to maintain a clean and organized work environment.

- Consider including a portfolio of your work to demonstrate your skills and capabilities.

Essential Experience Highlights for a Strong Powder Cutting Operator Resume

- Operate and maintain powder cutting machines, including plasma cutters, oxy-fuel cutters, laser cutters, and water jet cutters

- Interpret engineering drawings and specifications to determine cutting parameters

- Set up and adjust cutting machines according to specified tolerances

- Monitor cutting processes and make adjustments as needed to ensure quality and efficiency

- Perform routine maintenance and troubleshooting on cutting machines

- Adhere to all safety protocols and regulations

- Maintain a clean and organized work area

Frequently Asked Questions (FAQ’s) For Powder Cutting Operator

What are the key skills required to be a successful Powder Cutting Operator?

The key skills required to be a successful Powder Cutting Operator include proficiency in operating various cutting machines, such as plasma cutters, oxy-fuel cutters, laser cutters, and water jet cutters. Additionally, a strong understanding of CNC programming and automated cutting processes is essential. Other important skills include attention to detail, precision, and the ability to work independently.

What are the different types of cutting machines used by Powder Cutting Operators?

Powder Cutting Operators use a variety of cutting machines, including plasma cutters, oxy-fuel cutters, laser cutters, and water jet cutters. Each type of cutting machine has its own advantages and disadvantages, and the choice of which machine to use will depend on the specific application.

What are the safety protocols that Powder Cutting Operators must follow?

Powder Cutting Operators must follow a number of safety protocols to protect themselves and others from potential hazards. These protocols include wearing appropriate personal protective equipment, such as safety glasses, gloves, and earplugs. Additionally, they must be familiar with the proper handling and storage of cutting gases and other hazardous materials.

What are the career advancement opportunities for Powder Cutting Operators?

Powder Cutting Operators with experience and a proven track record can advance to supervisory or management positions. Additionally, they may be able to specialize in a particular type of cutting process, such as plasma cutting or laser cutting.

What is the job outlook for Powder Cutting Operators?

The job outlook for Powder Cutting Operators is expected to be good over the next few years. The demand for skilled metalworkers is growing, and Powder Cutting Operators are an essential part of the manufacturing process.

What are the educational requirements to become a Powder Cutting Operator?

Most Powder Cutting Operators have a high school diploma or equivalent. However, some employers may prefer candidates with an associate’s degree in welding technology or a related field.

What are the personality traits of successful Powder Cutting Operators?

Successful Powder Cutting Operators are typically detail-oriented, precise, and have a strong work ethic. They are also able to work independently and as part of a team.

What are the physical demands of being a Powder Cutting Operator?

Powder Cutting Operators must be able to stand for long periods of time and perform repetitive motions. They may also need to lift heavy objects and work in hot and noisy environments.