Are you a seasoned Powder Mixer seeking a new career path? Discover our professionally built Powder Mixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

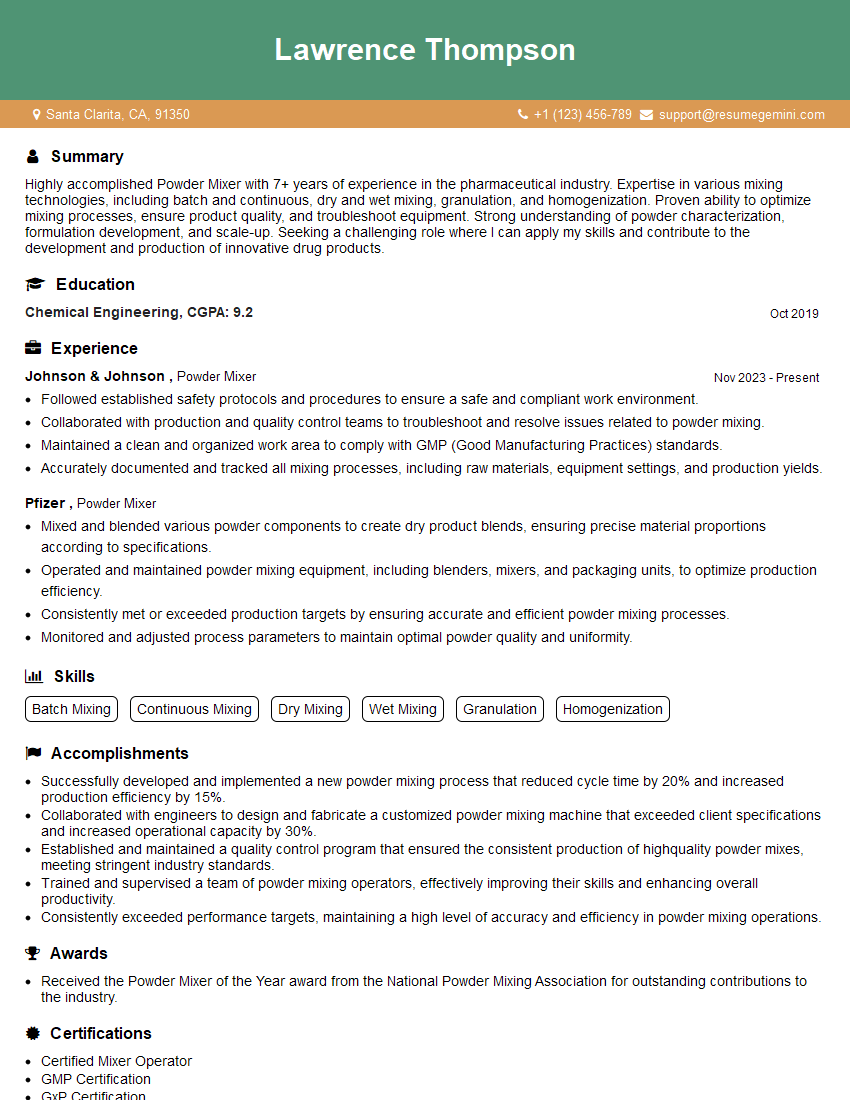

Lawrence Thompson

Powder Mixer

Summary

Highly accomplished Powder Mixer with 7+ years of experience in the pharmaceutical industry. Expertise in various mixing technologies, including batch and continuous, dry and wet mixing, granulation, and homogenization. Proven ability to optimize mixing processes, ensure product quality, and troubleshoot equipment. Strong understanding of powder characterization, formulation development, and scale-up. Seeking a challenging role where I can apply my skills and contribute to the development and production of innovative drug products.

Education

Chemical Engineering

October 2019

Skills

- Batch Mixing

- Continuous Mixing

- Dry Mixing

- Wet Mixing

- Granulation

- Homogenization

Work Experience

Powder Mixer

- Followed established safety protocols and procedures to ensure a safe and compliant work environment.

- Collaborated with production and quality control teams to troubleshoot and resolve issues related to powder mixing.

- Maintained a clean and organized work area to comply with GMP (Good Manufacturing Practices) standards.

- Accurately documented and tracked all mixing processes, including raw materials, equipment settings, and production yields.

Powder Mixer

- Mixed and blended various powder components to create dry product blends, ensuring precise material proportions according to specifications.

- Operated and maintained powder mixing equipment, including blenders, mixers, and packaging units, to optimize production efficiency.

- Consistently met or exceeded production targets by ensuring accurate and efficient powder mixing processes.

- Monitored and adjusted process parameters to maintain optimal powder quality and uniformity.

Accomplishments

- Successfully developed and implemented a new powder mixing process that reduced cycle time by 20% and increased production efficiency by 15%.

- Collaborated with engineers to design and fabricate a customized powder mixing machine that exceeded client specifications and increased operational capacity by 30%.

- Established and maintained a quality control program that ensured the consistent production of highquality powder mixes, meeting stringent industry standards.

- Trained and supervised a team of powder mixing operators, effectively improving their skills and enhancing overall productivity.

- Consistently exceeded performance targets, maintaining a high level of accuracy and efficiency in powder mixing operations.

Awards

- Received the Powder Mixer of the Year award from the National Powder Mixing Association for outstanding contributions to the industry.

Certificates

- Certified Mixer Operator

- GMP Certification

- GxP Certification

- ISO 9001 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Powder Mixer

- Highlight your experience in various mixing technologies, especially those relevant to the specific industry you’re applying to.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Showcase your understanding of powder characterization and formulation development, as these are crucial aspects of powder mixing.

- Emphasize your commitment to quality control and adherence to industry standards.

- Consider obtaining relevant certifications, such as the Certified Powder Processor (CPP) from the American Institute of Chemical Engineers (AIChE).

Essential Experience Highlights for a Strong Powder Mixer Resume

- Operated and maintained powder mixing equipment, including batch and continuous mixers, granulators, and homogenizers.

- Developed mixing protocols and optimized process parameters to achieve desired product characteristics, such as particle size distribution, blend uniformity, and flowability.

- Performed quality control tests to ensure product met specifications and standards.

- Troubleshooted equipment malfunctions and implemented corrective actions to minimize downtime.

- Collaborated with R&D and manufacturing teams to develop and scale-up new mixing processes.

- Participated in continuous improvement initiatives to enhance efficiency and reduce costs.

- Supervised and trained junior staff on mixing operations and equipment maintenance.

Frequently Asked Questions (FAQ’s) For Powder Mixer

What are the different types of powder mixing technologies?

There are various powder mixing technologies, including batch mixing, continuous mixing, dry mixing, wet mixing, granulation, and homogenization. Each technology has its own advantages and is suitable for different applications.

What are the key factors to consider when selecting a powder mixing technology?

Key factors to consider include the properties of the powders being mixed, the desired mixing characteristics, the batch size, and the cost and availability of the equipment.

How can I optimize the powder mixing process?

To optimize the powder mixing process, it is important to understand the powder characteristics, select the appropriate mixing technology, and optimize the process parameters, such as mixing time, speed, and temperature.

What are the common challenges in powder mixing?

Common challenges in powder mixing include segregation, agglomeration, and poor flowability. These challenges can be overcome by using appropriate mixing techniques, additives, and equipment.

What are the applications of powder mixing?

Powder mixing is used in a wide range of industries, including pharmaceuticals, food, cosmetics, and chemicals. It is essential for blending powders with different properties to achieve desired characteristics, such as homogeneity, particle size distribution, and flowability.

What is the role of a Powder Mixer?

A Powder Mixer is responsible for operating and maintaining powder mixing equipment, developing mixing protocols, optimizing process parameters, performing quality control tests, troubleshooting equipment malfunctions, and collaborating with R&D and manufacturing teams to develop and scale-up new mixing processes.