Are you a seasoned Pre-Assembly Printed Circuit Board Inspector seeking a new career path? Discover our professionally built Pre-Assembly Printed Circuit Board Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

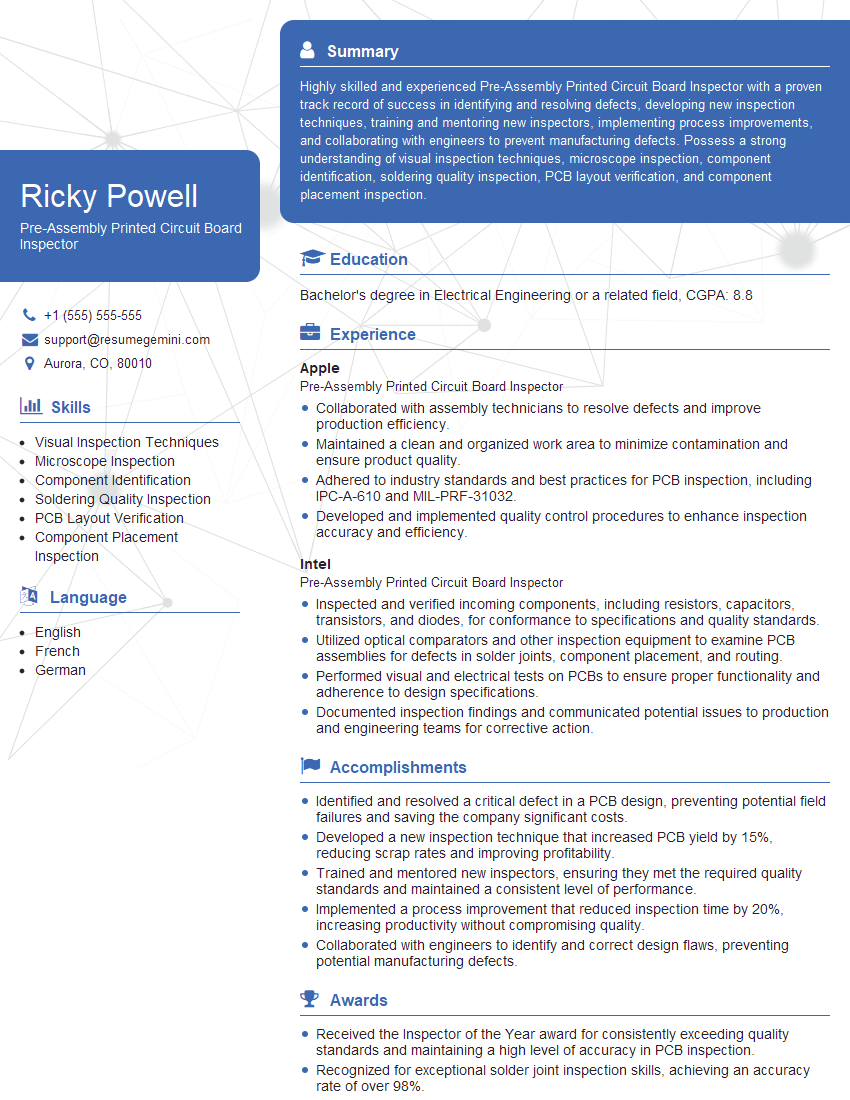

Ricky Powell

Pre-Assembly Printed Circuit Board Inspector

Summary

Highly skilled and experienced Pre-Assembly Printed Circuit Board Inspector with a proven track record of success in identifying and resolving defects, developing new inspection techniques, training and mentoring new inspectors, implementing process improvements, and collaborating with engineers to prevent manufacturing defects. Possess a strong understanding of visual inspection techniques, microscope inspection, component identification, soldering quality inspection, PCB layout verification, and component placement inspection.

Education

Bachelor’s degree in Electrical Engineering or a related field

April 2019

Skills

- Visual Inspection Techniques

- Microscope Inspection

- Component Identification

- Soldering Quality Inspection

- PCB Layout Verification

- Component Placement Inspection

Work Experience

Pre-Assembly Printed Circuit Board Inspector

- Collaborated with assembly technicians to resolve defects and improve production efficiency.

- Maintained a clean and organized work area to minimize contamination and ensure product quality.

- Adhered to industry standards and best practices for PCB inspection, including IPC-A-610 and MIL-PRF-31032.

- Developed and implemented quality control procedures to enhance inspection accuracy and efficiency.

Pre-Assembly Printed Circuit Board Inspector

- Inspected and verified incoming components, including resistors, capacitors, transistors, and diodes, for conformance to specifications and quality standards.

- Utilized optical comparators and other inspection equipment to examine PCB assemblies for defects in solder joints, component placement, and routing.

- Performed visual and electrical tests on PCBs to ensure proper functionality and adherence to design specifications.

- Documented inspection findings and communicated potential issues to production and engineering teams for corrective action.

Accomplishments

- Identified and resolved a critical defect in a PCB design, preventing potential field failures and saving the company significant costs.

- Developed a new inspection technique that increased PCB yield by 15%, reducing scrap rates and improving profitability.

- Trained and mentored new inspectors, ensuring they met the required quality standards and maintained a consistent level of performance.

- Implemented a process improvement that reduced inspection time by 20%, increasing productivity without compromising quality.

- Collaborated with engineers to identify and correct design flaws, preventing potential manufacturing defects.

Awards

- Received the Inspector of the Year award for consistently exceeding quality standards and maintaining a high level of accuracy in PCB inspection.

- Recognized for exceptional solder joint inspection skills, achieving an accuracy rate of over 98%.

- Received Safety Champion award for maintaining a spotless safety record and promoting a culture of safety in the workplace.

- Recognized for outstanding attention to detail and ability to identify subtle defects in complex PCBs.

Certificates

- IPCA610 Certified Inspector

- IPCSM782 Certified Inspector

- ASQ Certified Quality Inspector (CQI)

- ISO 9001 Internal Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pre-Assembly Printed Circuit Board Inspector

- Highlight your experience in identifying and resolving defects, as this is a critical skill for Pre-Assembly Printed Circuit Board Inspectors.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Use industry-specific keywords in your resume to make it more relevant to potential employers.

- Proofread your resume carefully before submitting it to ensure there are no errors.

- Consider getting your resume reviewed by a career counselor or professional resume writer to ensure it is well-written and effective.

Essential Experience Highlights for a Strong Pre-Assembly Printed Circuit Board Inspector Resume

- Inspect pre-assembled printed circuit boards (PCBs) for defects using visual and microscopic techniques.

- Identify and resolve defects in components, soldering, and PCB layout.

- Develop and implement new inspection techniques to improve PCB yield and reduce scrap rates.

- Train and mentor new inspectors to ensure they meet the required quality standards.

- Implement process improvements to reduce inspection time and increase productivity.

- Collaborate with engineers to identify and correct design flaws that could lead to manufacturing defects.

- Maintain a clean and organized work area and adhere to all safety protocols.

Frequently Asked Questions (FAQ’s) For Pre-Assembly Printed Circuit Board Inspector

What are the main responsibilities of a Pre-Assembly Printed Circuit Board Inspector?

Pre-Assembly Printed Circuit Board Inspectors are responsible for inspecting PCBs for defects before they are assembled. They use visual and microscopic techniques to identify defects in components, soldering, and PCB layout. They also develop and implement new inspection techniques to improve PCB yield and reduce scrap rates.

What are the qualifications for becoming a Pre-Assembly Printed Circuit Board Inspector?

Most Pre-Assembly Printed Circuit Board Inspectors have a bachelor’s degree in electrical engineering or a related field. They also have experience in visual and microscopic inspection techniques, as well as a strong understanding of PCB layout and component placement.

What is the job outlook for Pre-Assembly Printed Circuit Board Inspectors?

The job outlook for Pre-Assembly Printed Circuit Board Inspectors is expected to be good over the next few years. The demand for PCBs is growing due to the increasing popularity of electronic devices. As a result, there is a need for qualified inspectors to ensure that PCBs are manufactured to the highest quality standards.

What are the benefits of working as a Pre-Assembly Printed Circuit Board Inspector?

Pre-Assembly Printed Circuit Board Inspectors can enjoy a number of benefits, including a competitive salary, good benefits, and the opportunity to work in a challenging and rewarding field. They also have the opportunity to learn about new technologies and work with a variety of people.

What are the challenges of working as a Pre-Assembly Printed Circuit Board Inspector?

Pre-Assembly Printed Circuit Board Inspectors can face a number of challenges, including working with hazardous materials, working in a fast-paced environment, and meeting tight deadlines. They also need to be able to work independently and be able to identify and resolve defects quickly and accurately.

What is the salary range for Pre-Assembly Printed Circuit Board Inspectors?

The salary range for Pre-Assembly Printed Circuit Board Inspectors can vary depending on their experience, education, and location. However, most Pre-Assembly Printed Circuit Board Inspectors can expect to earn between $30,000 and $60,000 per year.

What are the advancement opportunities for Pre-Assembly Printed Circuit Board Inspectors?

Pre-Assembly Printed Circuit Board Inspectors can advance to a number of different positions, including Quality Control Manager, Manufacturing Engineer, and Product Engineer. They can also start their own businesses or become consultants.