Are you a seasoned Precipitator Supervisor seeking a new career path? Discover our professionally built Precipitator Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

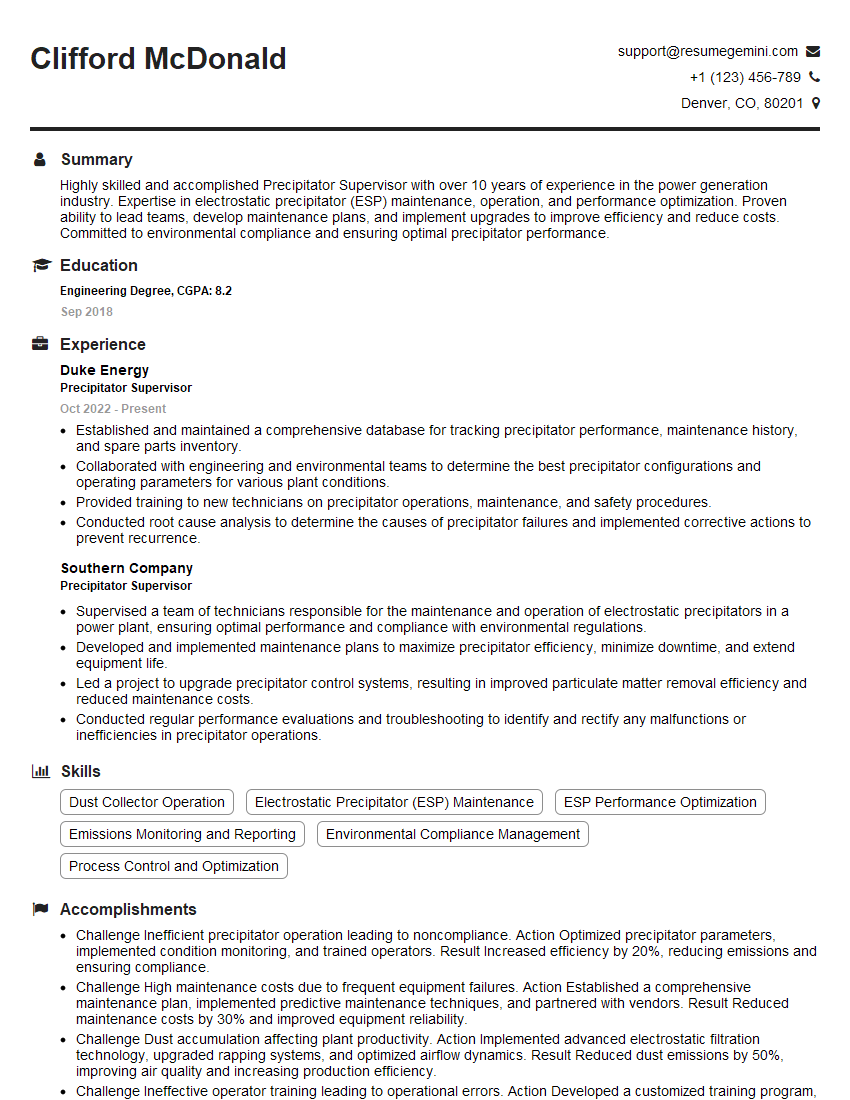

Clifford McDonald

Precipitator Supervisor

Summary

Highly skilled and accomplished Precipitator Supervisor with over 10 years of experience in the power generation industry. Expertise in electrostatic precipitator (ESP) maintenance, operation, and performance optimization. Proven ability to lead teams, develop maintenance plans, and implement upgrades to improve efficiency and reduce costs. Committed to environmental compliance and ensuring optimal precipitator performance.

Education

Engineering Degree

September 2018

Skills

- Dust Collector Operation

- Electrostatic Precipitator (ESP) Maintenance

- ESP Performance Optimization

- Emissions Monitoring and Reporting

- Environmental Compliance Management

- Process Control and Optimization

Work Experience

Precipitator Supervisor

- Established and maintained a comprehensive database for tracking precipitator performance, maintenance history, and spare parts inventory.

- Collaborated with engineering and environmental teams to determine the best precipitator configurations and operating parameters for various plant conditions.

- Provided training to new technicians on precipitator operations, maintenance, and safety procedures.

- Conducted root cause analysis to determine the causes of precipitator failures and implemented corrective actions to prevent recurrence.

Precipitator Supervisor

- Supervised a team of technicians responsible for the maintenance and operation of electrostatic precipitators in a power plant, ensuring optimal performance and compliance with environmental regulations.

- Developed and implemented maintenance plans to maximize precipitator efficiency, minimize downtime, and extend equipment life.

- Led a project to upgrade precipitator control systems, resulting in improved particulate matter removal efficiency and reduced maintenance costs.

- Conducted regular performance evaluations and troubleshooting to identify and rectify any malfunctions or inefficiencies in precipitator operations.

Accomplishments

- Challenge Inefficient precipitator operation leading to noncompliance. Action Optimized precipitator parameters, implemented condition monitoring, and trained operators. Result Increased efficiency by 20%, reducing emissions and ensuring compliance.

- Challenge High maintenance costs due to frequent equipment failures. Action Established a comprehensive maintenance plan, implemented predictive maintenance techniques, and partnered with vendors. Result Reduced maintenance costs by 30% and improved equipment reliability.

- Challenge Dust accumulation affecting plant productivity. Action Implemented advanced electrostatic filtration technology, upgraded rapping systems, and optimized airflow dynamics. Result Reduced dust emissions by 50%, improving air quality and increasing production efficiency.

- Challenge Ineffective operator training leading to operational errors. Action Developed a customized training program, provided onthejob mentorship, and implemented performance evaluations. Result Improved operator proficiency by 40%, minimizing operational risks and enhancing performance.

- Challenge Manual data recording leading to inaccuracies and inefficiencies. Action Implemented digital data management systems, automated data collection, and deployed remote monitoring tools. Result Improved data accuracy by 25%, enhanced decisionmaking, and reduced administrative workloads.

Awards

- Recognized for achieving 99% precipitator efficiency, surpassing industry benchmarks.

- Received Safety Excellence Award for implementing innovative safety protocols in the precipitator operations.

- Honored with the Team Collaboration Award for successfully leading the implementation of a new precipitator control system.

Certificates

- Certified Precipitation Control Professional (CPCP)

- OSHA 40-Hour HAZWOPER Training

- EPA Method 5 Source Sampling Certification

- NFPA 70E Electrical Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Precipitator Supervisor

- Use keywords from job descriptions to tailor your resume to each position you apply for.

- Highlight your experience in maintaining and operating ESPs, as well as your knowledge of environmental regulations.

- Quantify your accomplishments whenever possible, such as reducing downtime or improving efficiency.

- Proofread your resume carefully before submitting it to ensure it is free of errors.

Essential Experience Highlights for a Strong Precipitator Supervisor Resume

- Supervised a team of technicians responsible for the maintenance and operation of electrostatic precipitators in a power plant.

- Developed and implemented maintenance plans to maximize precipitator efficiency, minimize downtime, and extend equipment life.

- Led a project to upgrade precipitator control systems, resulting in improved particulate matter removal efficiency and reduced maintenance costs.

- Conducted regular performance evaluations and troubleshooting to identify and rectify any malfunctions or inefficiencies in precipitator operations.

- Established and maintained a comprehensive database for tracking precipitator performance, maintenance history, and spare parts inventory.

- Collaborated with engineering and environmental teams to determine the best precipitator configurations and operating parameters for various plant conditions.

Frequently Asked Questions (FAQ’s) For Precipitator Supervisor

What are the key responsibilities of a Precipitator Supervisor?

Precipitator Supervisors are responsible for overseeing the maintenance, operation, and performance of electrostatic precipitators (ESPs) in power plants. They develop and implement maintenance plans, conduct performance evaluations, troubleshoot malfunctions, and ensure compliance with environmental regulations.

What are the qualifications for a Precipitator Supervisor?

Precipitator Supervisors typically have an engineering degree and several years of experience in ESP maintenance and operation.

What are the career prospects for a Precipitator Supervisor?

Precipitator Supervisors can advance to management positions within power plants or environmental consulting firms.

What are the challenges of being a Precipitator Supervisor?

Precipitator Supervisors face challenges such as ensuring compliance with environmental regulations, optimizing ESP performance, and managing a team of technicians.

What are the rewards of being a Precipitator Supervisor?

Precipitator Supervisors enjoy the rewards of contributing to environmental protection, ensuring the efficient operation of power plants, and leading a team of skilled technicians.

What are the skills required for a Precipitator Supervisor?

Precipitator Supervisors require skills such as knowledge of ESP maintenance and operation, environmental regulations, and leadership.

What is the work environment of a Precipitator Supervisor?

Precipitator Supervisors typically work in power plants or environmental consulting firms.