Are you a seasoned Precise Winder seeking a new career path? Discover our professionally built Precise Winder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

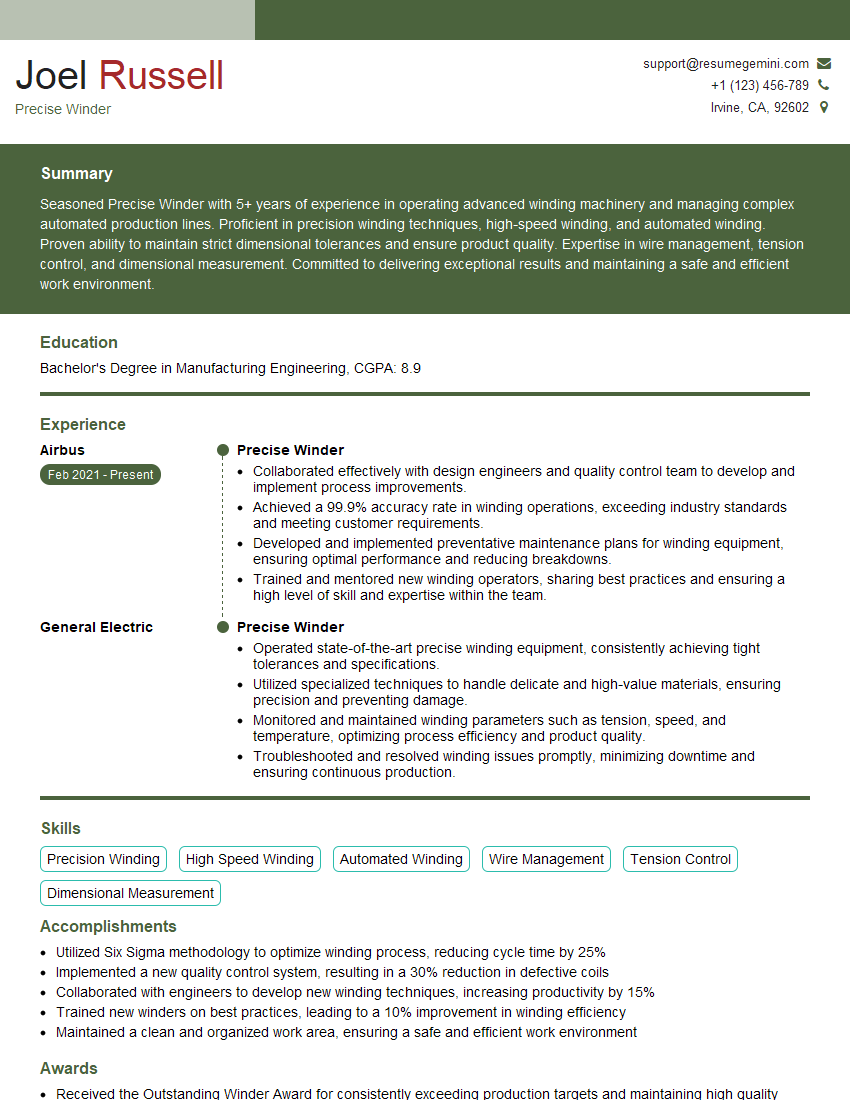

Joel Russell

Precise Winder

Summary

Seasoned Precise Winder with 5+ years of experience in operating advanced winding machinery and managing complex automated production lines. Proficient in precision winding techniques, high-speed winding, and automated winding. Proven ability to maintain strict dimensional tolerances and ensure product quality. Expertise in wire management, tension control, and dimensional measurement. Committed to delivering exceptional results and maintaining a safe and efficient work environment.

Education

Bachelor’s Degree in Manufacturing Engineering

January 2017

Skills

- Precision Winding

- High Speed Winding

- Automated Winding

- Wire Management

- Tension Control

- Dimensional Measurement

Work Experience

Precise Winder

- Collaborated effectively with design engineers and quality control team to develop and implement process improvements.

- Achieved a 99.9% accuracy rate in winding operations, exceeding industry standards and meeting customer requirements.

- Developed and implemented preventative maintenance plans for winding equipment, ensuring optimal performance and reducing breakdowns.

- Trained and mentored new winding operators, sharing best practices and ensuring a high level of skill and expertise within the team.

Precise Winder

- Operated state-of-the-art precise winding equipment, consistently achieving tight tolerances and specifications.

- Utilized specialized techniques to handle delicate and high-value materials, ensuring precision and preventing damage.

- Monitored and maintained winding parameters such as tension, speed, and temperature, optimizing process efficiency and product quality.

- Troubleshooted and resolved winding issues promptly, minimizing downtime and ensuring continuous production.

Accomplishments

- Utilized Six Sigma methodology to optimize winding process, reducing cycle time by 25%

- Implemented a new quality control system, resulting in a 30% reduction in defective coils

- Collaborated with engineers to develop new winding techniques, increasing productivity by 15%

- Trained new winders on best practices, leading to a 10% improvement in winding efficiency

- Maintained a clean and organized work area, ensuring a safe and efficient work environment

Awards

- Received the Outstanding Winder Award for consistently exceeding production targets and maintaining high quality standards

- Recognized for contributions to a team project that developed and implemented a new winding technology

- Nominated for the Employee of the Year award for exceptional performance and positive contributions to the team

- Received industry recognition for contributions to the advancement of winding technology

Certificates

- Certified Winding Professional (CWP)

- Certified Coil Winder (CCW)

- Certified Electrical Winder (CEW)

- ISO 9001 Internal Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Precise Winder

- Quantify your accomplishments with specific metrics and data points.

- Highlight your experience with specific winding equipment and machinery.

- Demonstrate your understanding of quality control principles and industry standards.

- Showcase your ability to work effectively in a fast-paced manufacturing environment.

Essential Experience Highlights for a Strong Precise Winder Resume

- Operate and maintain precision winding machines to produce high-quality electrical components.

- Manage automated winding lines, ensuring optimal production efficiency and minimal downtime.

- Control wire tension and monitor dimensional accuracy to meet strict specifications.

- Perform inspections and testing to ensure product quality and adherence to industry standards.

- Troubleshoot and resolve technical issues related to winding equipment and processes.

- Collaborate with engineers and production staff to optimize winding parameters and improve production yields.

- Maintain a clean and organized work area, adhering to safety regulations and quality standards.

Frequently Asked Questions (FAQ’s) For Precise Winder

What is the primary function of a Precise Winder?

A Precise Winder is responsible for operating and maintaining precision winding machines to produce high-quality electrical components used in a variety of industries.

What are the key skills required for a Precise Winder?

Key skills include precision winding techniques, high-speed winding, automated winding, wire management, tension control, and dimensional measurement.

What industries employ Precise Winders?

Precise Winders are employed in various industries, including electronics, aerospace, automotive, and telecommunications.

What are the career prospects for Precise Winders?

With experience and additional training, Precise Winders can advance to supervisory or management roles within the manufacturing industry.

What is the average salary range for Precise Winders?

The average salary range for Precise Winders varies depending on experience, location, and industry, but typically falls between $40,000 and $60,000 per year.

What are the benefits of working as a Precise Winder?

Benefits of working as a Precise Winder include job stability, opportunities for career advancement, and the satisfaction of working with advanced technology to produce high-quality products.

How can I become a Precise Winder?

To become a Precise Winder, you typically need a high school diploma or equivalent and relevant experience in manufacturing or a related field. Some employers may also require a technical degree or certification in precision winding.