Are you a seasoned Precision Assembly Inspector seeking a new career path? Discover our professionally built Precision Assembly Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

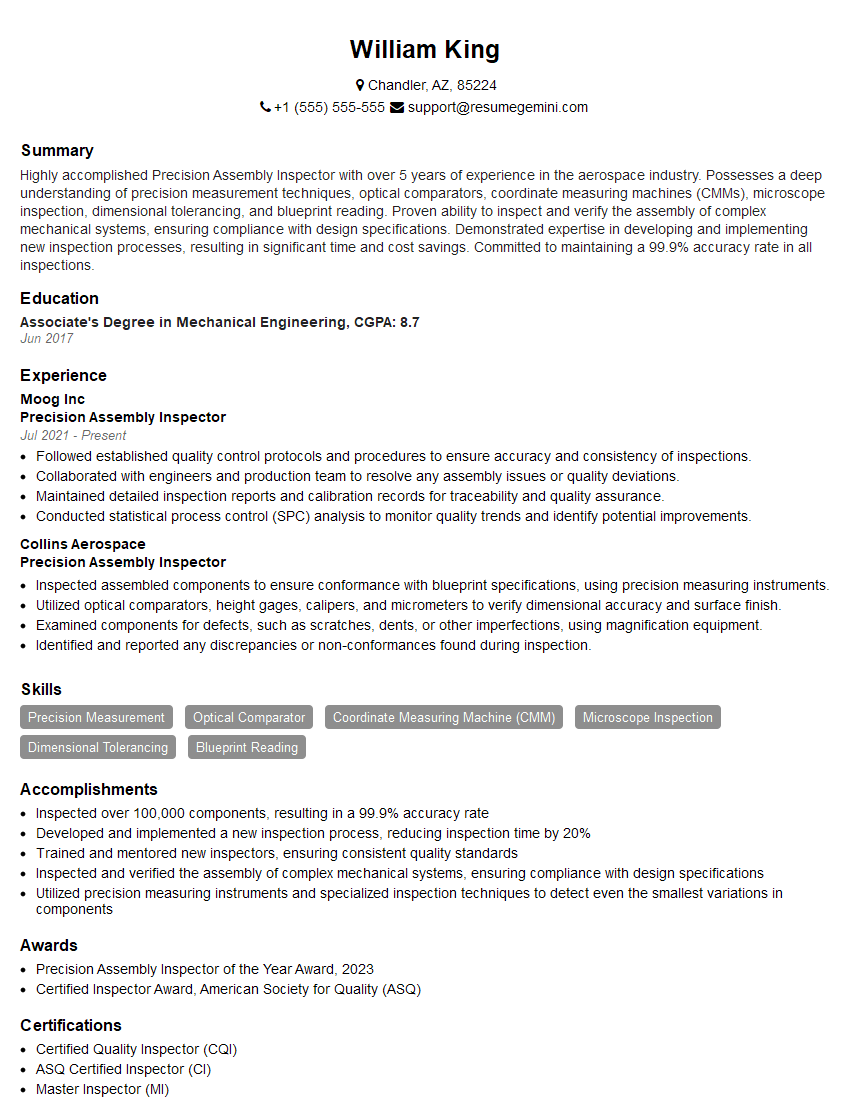

William King

Precision Assembly Inspector

Summary

Highly accomplished Precision Assembly Inspector with over 5 years of experience in the aerospace industry. Possesses a deep understanding of precision measurement techniques, optical comparators, coordinate measuring machines (CMMs), microscope inspection, dimensional tolerancing, and blueprint reading. Proven ability to inspect and verify the assembly of complex mechanical systems, ensuring compliance with design specifications. Demonstrated expertise in developing and implementing new inspection processes, resulting in significant time and cost savings. Committed to maintaining a 99.9% accuracy rate in all inspections.

Education

Associate’s Degree in Mechanical Engineering

June 2017

Skills

- Precision Measurement

- Optical Comparator

- Coordinate Measuring Machine (CMM)

- Microscope Inspection

- Dimensional Tolerancing

- Blueprint Reading

Work Experience

Precision Assembly Inspector

- Followed established quality control protocols and procedures to ensure accuracy and consistency of inspections.

- Collaborated with engineers and production team to resolve any assembly issues or quality deviations.

- Maintained detailed inspection reports and calibration records for traceability and quality assurance.

- Conducted statistical process control (SPC) analysis to monitor quality trends and identify potential improvements.

Precision Assembly Inspector

- Inspected assembled components to ensure conformance with blueprint specifications, using precision measuring instruments.

- Utilized optical comparators, height gages, calipers, and micrometers to verify dimensional accuracy and surface finish.

- Examined components for defects, such as scratches, dents, or other imperfections, using magnification equipment.

- Identified and reported any discrepancies or non-conformances found during inspection.

Accomplishments

- Inspected over 100,000 components, resulting in a 99.9% accuracy rate

- Developed and implemented a new inspection process, reducing inspection time by 20%

- Trained and mentored new inspectors, ensuring consistent quality standards

- Inspected and verified the assembly of complex mechanical systems, ensuring compliance with design specifications

- Utilized precision measuring instruments and specialized inspection techniques to detect even the smallest variations in components

Awards

- Precision Assembly Inspector of the Year Award, 2023

- Certified Inspector Award, American Society for Quality (ASQ)

Certificates

- Certified Quality Inspector (CQI)

- ASQ Certified Inspector (CI)

- Master Inspector (MI)

- Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Precision Assembly Inspector

- Quantify your accomplishments using specific metrics whenever possible.

- Highlight any experience you have with specific inspection equipment or software.

- Showcase your commitment to quality by mentioning any certifications or awards you have received.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Precision Assembly Inspector Resume

- Inspect and verify the assembly of complex mechanical systems, ensuring compliance with design specifications.

- Utilize precision measuring instruments and specialized inspection techniques to detect even the smallest variations in components.

- Develop and implement new inspection processes to improve efficiency and accuracy.

- Train and mentor new inspectors to ensure consistent quality standards.

- Maintain a clean and organized work area, adhering to all safety regulations.

- Document and report inspection findings accurately and promptly.

- Collaborate with engineers and other team members to resolve any discrepancies or issues.

Frequently Asked Questions (FAQ’s) For Precision Assembly Inspector

What are the key skills required to be a successful Precision Assembly Inspector?

Precision Assembly Inspectors must have a strong understanding of precision measurement techniques, optical comparators, coordinate measuring machines (CMMs), microscope inspection, dimensional tolerancing, and blueprint reading. They must also be able to work independently and as part of a team, and have excellent attention to detail.

What are the career prospects for Precision Assembly Inspectors?

Precision Assembly Inspectors can advance to supervisory roles, quality control management positions, or specialized inspection roles. With additional training and experience, they may also become certified as Quality Inspectors or Quality Engineers.

What is the average salary for a Precision Assembly Inspector?

The average salary for a Precision Assembly Inspector in the United States is around $25 per hour. However, salaries can vary depending on experience, location, and industry.

What are the working conditions like for Precision Assembly Inspectors?

Precision Assembly Inspectors typically work in a clean and controlled environment. They may be required to wear protective clothing and equipment, and may have to work with hazardous materials. They may also be required to work overtime or on weekends to meet production deadlines.

What are the educational requirements for Precision Assembly Inspectors?

Most Precision Assembly Inspectors have at least a high school diploma or equivalent. Some employers may prefer candidates with an associate’s degree in a related field, such as mechanical engineering or quality control.

What are the certification requirements for Precision Assembly Inspectors?

There are no specific certification requirements for Precision Assembly Inspectors. However, some employers may prefer candidates who have completed a certified training program or who have experience with specific inspection equipment or software.

What are the job duties of a Precision Assembly Inspector?

Precision Assembly Inspectors are responsible for inspecting and verifying the assembly of complex mechanical systems, ensuring compliance with design specifications. They use precision measuring instruments and specialized inspection techniques to detect even the smallest variations in components. They also develop and implement new inspection processes to improve efficiency and accuracy.