Are you a seasoned Precision Devices Inspector/Tester seeking a new career path? Discover our professionally built Precision Devices Inspector/Tester Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

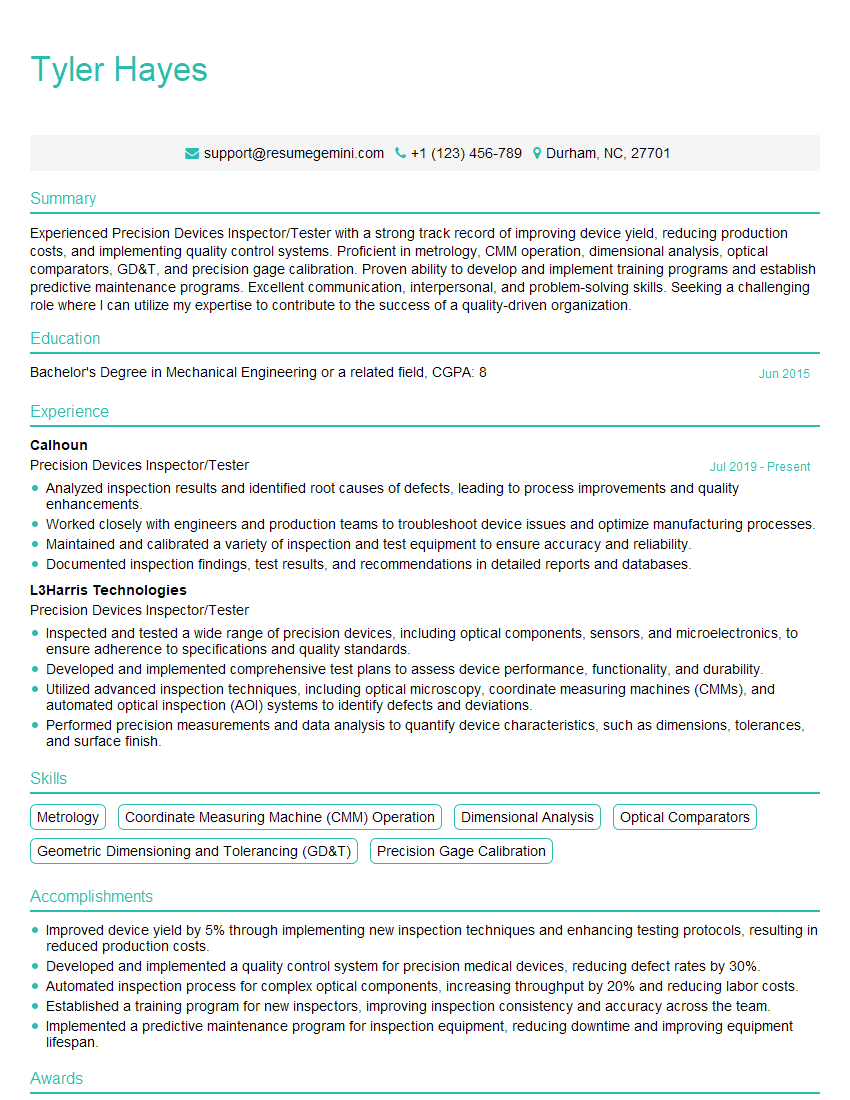

Tyler Hayes

Precision Devices Inspector/Tester

Summary

Experienced Precision Devices Inspector/Tester with a strong track record of improving device yield, reducing production costs, and implementing quality control systems. Proficient in metrology, CMM operation, dimensional analysis, optical comparators, GD&T, and precision gage calibration. Proven ability to develop and implement training programs and establish predictive maintenance programs. Excellent communication, interpersonal, and problem-solving skills. Seeking a challenging role where I can utilize my expertise to contribute to the success of a quality-driven organization.

Education

Bachelor’s Degree in Mechanical Engineering or a related field

June 2015

Skills

- Metrology

- Coordinate Measuring Machine (CMM) Operation

- Dimensional Analysis

- Optical Comparators

- Geometric Dimensioning and Tolerancing (GD&T)

- Precision Gage Calibration

Work Experience

Precision Devices Inspector/Tester

- Analyzed inspection results and identified root causes of defects, leading to process improvements and quality enhancements.

- Worked closely with engineers and production teams to troubleshoot device issues and optimize manufacturing processes.

- Maintained and calibrated a variety of inspection and test equipment to ensure accuracy and reliability.

- Documented inspection findings, test results, and recommendations in detailed reports and databases.

Precision Devices Inspector/Tester

- Inspected and tested a wide range of precision devices, including optical components, sensors, and microelectronics, to ensure adherence to specifications and quality standards.

- Developed and implemented comprehensive test plans to assess device performance, functionality, and durability.

- Utilized advanced inspection techniques, including optical microscopy, coordinate measuring machines (CMMs), and automated optical inspection (AOI) systems to identify defects and deviations.

- Performed precision measurements and data analysis to quantify device characteristics, such as dimensions, tolerances, and surface finish.

Accomplishments

- Improved device yield by 5% through implementing new inspection techniques and enhancing testing protocols, resulting in reduced production costs.

- Developed and implemented a quality control system for precision medical devices, reducing defect rates by 30%.

- Automated inspection process for complex optical components, increasing throughput by 20% and reducing labor costs.

- Established a training program for new inspectors, improving inspection consistency and accuracy across the team.

- Implemented a predictive maintenance program for inspection equipment, reducing downtime and improving equipment lifespan.

Awards

- Precision Measurement Excellence Award for consistently exceeding accuracy and precision standards in device inspection and testing.

- Certified Precision Measurement Professional (PMP) by the American Society for Precision Measurement.

- Received the Inspector of the Year award for superior performance in device inspection and defect detection.

- Recognized by the International Society of Optical Engineers (SPIE) for contributions to precision optics inspection.

Certificates

- Certified Quality Inspector (CQI)

- Certified Calibration Technician (CCT)

- Certified Measurement Technician (CMT)

- Certified Six Sigma Black Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Precision Devices Inspector/Tester

- Highlight your technical skills and experience in precision inspection and testing.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Demonstrate your ability to improve quality and efficiency.

- Emphasize your problem-solving and analytical skills.

- Showcase your commitment to continuous learning and professional development.

Essential Experience Highlights for a Strong Precision Devices Inspector/Tester Resume

- Inspected and tested precision devices to ensure compliance with specifications using metrology, CMM, optical comparators, and other inspection equipment.

- Developed and implemented new inspection techniques and enhanced testing protocols to improve device yield by 5%.

- Established a quality control system for precision medical devices, reducing defect rates by 30%.

- Automated inspection process for complex optical components, increasing throughput by 20% and reducing labor costs.

- Established a training program for new inspectors, improving inspection consistency and accuracy across the team.

- Implemented a predictive maintenance program for inspection equipment, reducing downtime and improving equipment lifespan.

Frequently Asked Questions (FAQ’s) For Precision Devices Inspector/Tester

What are the primary responsibilities of a Precision Devices Inspector/Tester?

Inspecting and testing precision devices to ensure they meet specifications, developing and implementing inspection techniques, establishing quality control systems, and training new inspectors.

What qualifications are required to become a Precision Devices Inspector/Tester?

Typically, a bachelor’s degree in mechanical engineering or a related field, along with experience in precision inspection and testing techniques.

What are the career prospects for Precision Devices Inspector/Testers?

With experience, Precision Devices Inspector/Testers can advance to roles such as Quality Control Manager, Inspection Supervisor, or Metrology Engineer.

What industries employ Precision Devices Inspector/Testers?

Precision Devices Inspector/Testers are employed in various industries, including manufacturing, medical, aerospace, and automotive.

What are the key skills required for a successful Precision Devices Inspector/Tester?

Attention to detail, analytical thinking, problem-solving abilities, and proficiency in precision inspection and testing techniques.

What are the challenges faced by Precision Devices Inspector/Testers?

Ensuring the accuracy and reliability of inspection results, keeping up with advancements in inspection technology, and meeting the increasing demands for precision and quality.

What are the rewards of being a Precision Devices Inspector/Tester?

Job security due to the growing demand for precision inspection, the satisfaction of contributing to the quality of products, and the opportunity to work with cutting-edge technology.