Are you a seasoned Precision Inspector seeking a new career path? Discover our professionally built Precision Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

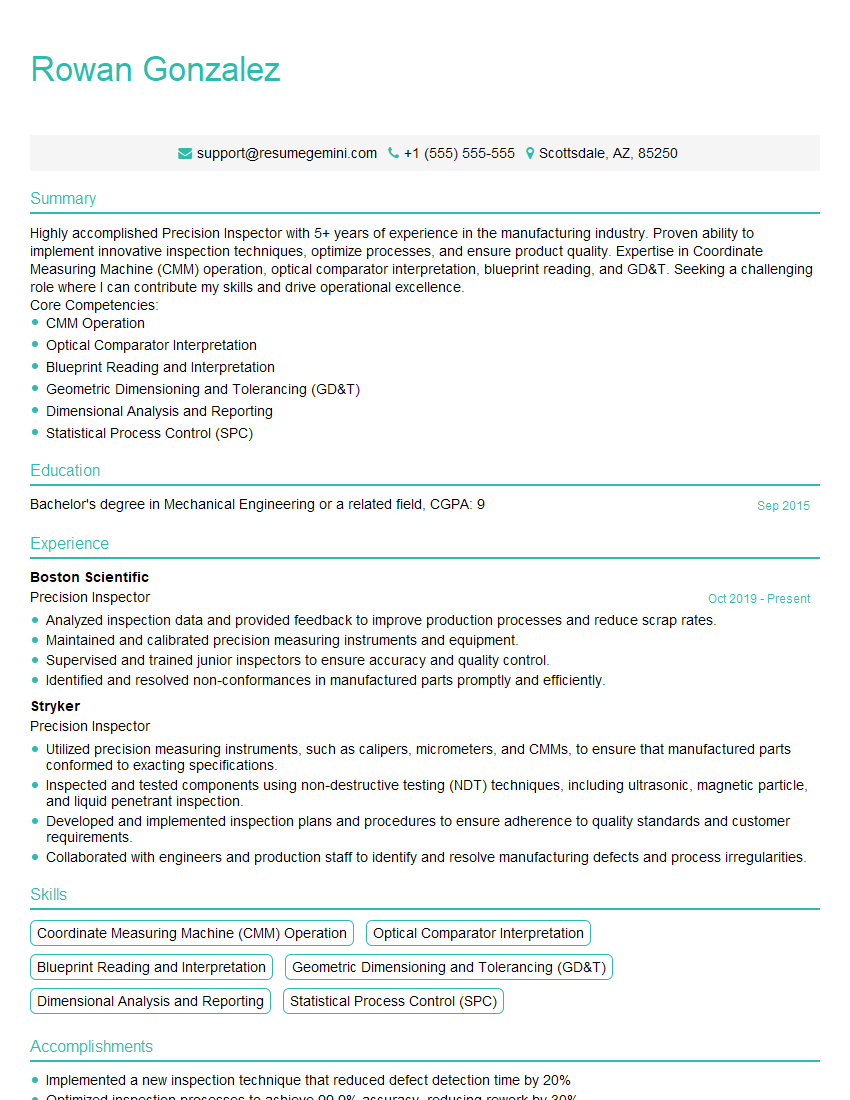

Rowan Gonzalez

Precision Inspector

Summary

Highly accomplished Precision Inspector with 5+ years of experience in the manufacturing industry. Proven ability to implement innovative inspection techniques, optimize processes, and ensure product quality. Expertise in Coordinate Measuring Machine (CMM) operation, optical comparator interpretation, blueprint reading, and GD&T. Seeking a challenging role where I can contribute my skills and drive operational excellence.

Core Competencies:

- CMM Operation

- Optical Comparator Interpretation

- Blueprint Reading and Interpretation

- Geometric Dimensioning and Tolerancing (GD&T)

- Dimensional Analysis and Reporting

- Statistical Process Control (SPC)

Education

Bachelor’s degree in Mechanical Engineering or a related field

September 2015

Skills

- Coordinate Measuring Machine (CMM) Operation

- Optical Comparator Interpretation

- Blueprint Reading and Interpretation

- Geometric Dimensioning and Tolerancing (GD&T)

- Dimensional Analysis and Reporting

- Statistical Process Control (SPC)

Work Experience

Precision Inspector

- Analyzed inspection data and provided feedback to improve production processes and reduce scrap rates.

- Maintained and calibrated precision measuring instruments and equipment.

- Supervised and trained junior inspectors to ensure accuracy and quality control.

- Identified and resolved non-conformances in manufactured parts promptly and efficiently.

Precision Inspector

- Utilized precision measuring instruments, such as calipers, micrometers, and CMMs, to ensure that manufactured parts conformed to exacting specifications.

- Inspected and tested components using non-destructive testing (NDT) techniques, including ultrasonic, magnetic particle, and liquid penetrant inspection.

- Developed and implemented inspection plans and procedures to ensure adherence to quality standards and customer requirements.

- Collaborated with engineers and production staff to identify and resolve manufacturing defects and process irregularities.

Accomplishments

- Implemented a new inspection technique that reduced defect detection time by 20%

- Optimized inspection processes to achieve 99.9% accuracy, reducing rework by 30%

- Developed a training program for new inspectors, improving their proficiency by 15%

- Identified and resolved a critical flaw in the manufacturing process, preventing a potential product recall

- Introduced automation into the inspection process, increasing efficiency by 25%

Awards

- Precision Inspection Excellence Award for exceeding quality standards by 15%

- Industry Recognition for Excellence in Dimensional Metrology

- Precision Inspection Certification from the American Society for Quality (ASQ)

- Recognition for implementing innovative inspection methodologies

Certificates

- Certified Precision Measurement Technician (CPMT)

- Certified Coordinate Measuring Machine (CMM) Technician

- Certified Optical Comparator Inspector

- Certified Quality Inspector (CQI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Precision Inspector

- Highlight your experience in using precision measuring instruments, such as CMMs and optical comparators.

- Quantify your accomplishments with specific metrics, such as reducing defect detection time or improving inspection accuracy.

- Showcase your knowledge of GD&T and other quality control principles.

- Emphasize your ability to work independently and as part of a team.

- Tailor your resume to the specific requirements of the job you are applying for.

Essential Experience Highlights for a Strong Precision Inspector Resume

- Conduct precision inspections using CMM, optical comparators, and other measuring instruments to ensure product conformance to specifications

- Interpret blueprints, technical drawings, and GD&T to determine inspection requirements

- Analyze inspection data, identify discrepancies, and determine root causes of defects

- Develop and implement inspection plans and procedures to improve efficiency and accuracy

- Train and mentor new inspectors, ensuring they meet quality standards

- Collaborate with engineers and production teams to resolve quality issues and improve manufacturing processes

- Maintain inspection equipment and ensure its calibration and functionality

Frequently Asked Questions (FAQ’s) For Precision Inspector

What are the key skills required to be a successful Precision Inspector?

Key skills for a Precision Inspector include CMM operation, optical comparator interpretation, blueprint reading and interpretation, GD&T, dimensional analysis and reporting, and statistical process control (SPC).

What is the role of a Precision Inspector in the manufacturing process?

Precision Inspectors play a vital role in ensuring product quality by conducting inspections to verify that products meet specifications. They analyze data, identify discrepancies, and determine the root cause of defects, helping to improve manufacturing processes and prevent product recalls.

What are the career prospects for Precision Inspectors?

Precision Inspectors can advance their careers by becoming Lead Inspectors, Quality Control Supervisors, or Quality Engineers. With experience and additional training, they can also move into management roles.

What are the educational requirements to become a Precision Inspector?

Most Precision Inspectors have a high school diploma or an associate’s degree in a related field, such as mechanical engineering or manufacturing technology.

What is the expected salary range for Precision Inspectors?

The salary range for Precision Inspectors can vary depending on experience, location, and industry. According to Salary.com, the median salary for Precision Inspectors in the United States is around $25,000.

What are the certifications available for Precision Inspectors?

Precision Inspectors can obtain certifications from organizations such as the American Society for Quality (ASQ) and the Coordinate Metrology Society (CMS) to demonstrate their skills and knowledge.