Are you a seasoned Pressure Test Operator seeking a new career path? Discover our professionally built Pressure Test Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

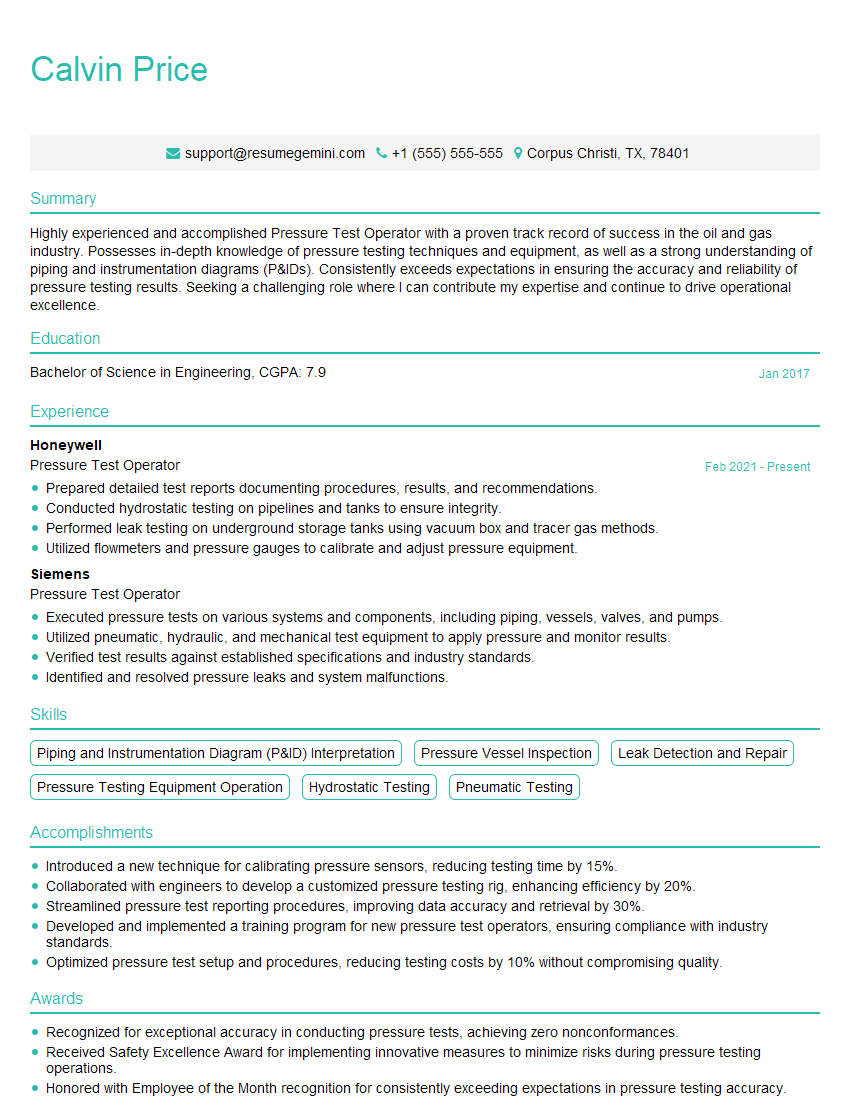

Calvin Price

Pressure Test Operator

Summary

Highly experienced and accomplished Pressure Test Operator with a proven track record of success in the oil and gas industry. Possesses in-depth knowledge of pressure testing techniques and equipment, as well as a strong understanding of piping and instrumentation diagrams (P&IDs). Consistently exceeds expectations in ensuring the accuracy and reliability of pressure testing results. Seeking a challenging role where I can contribute my expertise and continue to drive operational excellence.

Education

Bachelor of Science in Engineering

January 2017

Skills

- Piping and Instrumentation Diagram (P&ID) Interpretation

- Pressure Vessel Inspection

- Leak Detection and Repair

- Pressure Testing Equipment Operation

- Hydrostatic Testing

- Pneumatic Testing

Work Experience

Pressure Test Operator

- Prepared detailed test reports documenting procedures, results, and recommendations.

- Conducted hydrostatic testing on pipelines and tanks to ensure integrity.

- Performed leak testing on underground storage tanks using vacuum box and tracer gas methods.

- Utilized flowmeters and pressure gauges to calibrate and adjust pressure equipment.

Pressure Test Operator

- Executed pressure tests on various systems and components, including piping, vessels, valves, and pumps.

- Utilized pneumatic, hydraulic, and mechanical test equipment to apply pressure and monitor results.

- Verified test results against established specifications and industry standards.

- Identified and resolved pressure leaks and system malfunctions.

Accomplishments

- Introduced a new technique for calibrating pressure sensors, reducing testing time by 15%.

- Collaborated with engineers to develop a customized pressure testing rig, enhancing efficiency by 20%.

- Streamlined pressure test reporting procedures, improving data accuracy and retrieval by 30%.

- Developed and implemented a training program for new pressure test operators, ensuring compliance with industry standards.

- Optimized pressure test setup and procedures, reducing testing costs by 10% without compromising quality.

Awards

- Recognized for exceptional accuracy in conducting pressure tests, achieving zero nonconformances.

- Received Safety Excellence Award for implementing innovative measures to minimize risks during pressure testing operations.

- Honored with Employee of the Month recognition for consistently exceeding expectations in pressure testing accuracy.

- Awarded a certificate for proficiency in performing pressure testing on highpressure equipment.

Certificates

- ASME Boiler and Pressure Vessel Code

- National Board of Boiler and Pressure Vessel Inspectors (NBBI)

- American Petroleum Institute (API) 572

- National Association of Corrosion Engineers (NACE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pressure Test Operator

- Highlight your experience and expertise in pressure testing techniques and equipment.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your knowledge of industry standards and regulations, such as ASME and API.

- Emphasize your ability to work independently and as part of a team.

- Consider obtaining industry certifications, such as the Certified Pressure Test Operator (CPTO) certification offered by the American Society of Mechanical Engineers (ASME).

Essential Experience Highlights for a Strong Pressure Test Operator Resume

- Interpret piping and instrumentation diagrams (P&IDs) to identify pressure test points and determine appropriate test parameters.

- Operate pressure testing equipment, including pumps, gauges, and data loggers, to conduct hydrostatic and pneumatic testing.

- Conduct leak detection and repair procedures to ensure the integrity of pressure vessels and piping systems.

- Monitor pressure test results and provide timely feedback to engineers and project managers.

- Maintain and calibrate pressure testing equipment to ensure accuracy and reliability.

- Develop and implement pressure test procedures to optimize testing efficiency and safety.

- Train and mentor new pressure test operators to ensure compliance with industry standards and best practices.

Frequently Asked Questions (FAQ’s) For Pressure Test Operator

What is the primary role of a Pressure Test Operator?

The primary role of a Pressure Test Operator is to ensure the integrity and safety of pressure vessels and piping systems by conducting pressure testing and leak detection procedures.

What are the key skills required for a Pressure Test Operator?

Key skills for a Pressure Test Operator include knowledge of pressure testing techniques and equipment, interpretation of piping and instrumentation diagrams (P&IDs), leak detection and repair, and compliance with industry standards.

What industries employ Pressure Test Operators?

Pressure Test Operators are employed in various industries, including oil and gas, power generation, and manufacturing.

What are the career prospects for Pressure Test Operators?

Pressure Test Operators with experience and certifications can advance to roles such as Inspection Supervisor, Quality Control Manager, or Engineering Technician.

How can I improve my skills as a Pressure Test Operator?

To improve your skills as a Pressure Test Operator, consider obtaining industry certifications, attending training programs, and staying up-to-date on the latest testing techniques and equipment.

What are the safety precautions that Pressure Test Operators must follow?

Pressure Test Operators must follow strict safety precautions, including wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures, and adhering to industry standards.

What is the difference between hydrostatic testing and pneumatic testing?

Hydrostatic testing uses water as the test medium, while pneumatic testing uses compressed air or gas. Hydrostatic testing is typically used for lower pressure systems, while pneumatic testing is used for higher pressure systems.