Are you a seasoned Preventive Maintenance Coordinator seeking a new career path? Discover our professionally built Preventive Maintenance Coordinator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

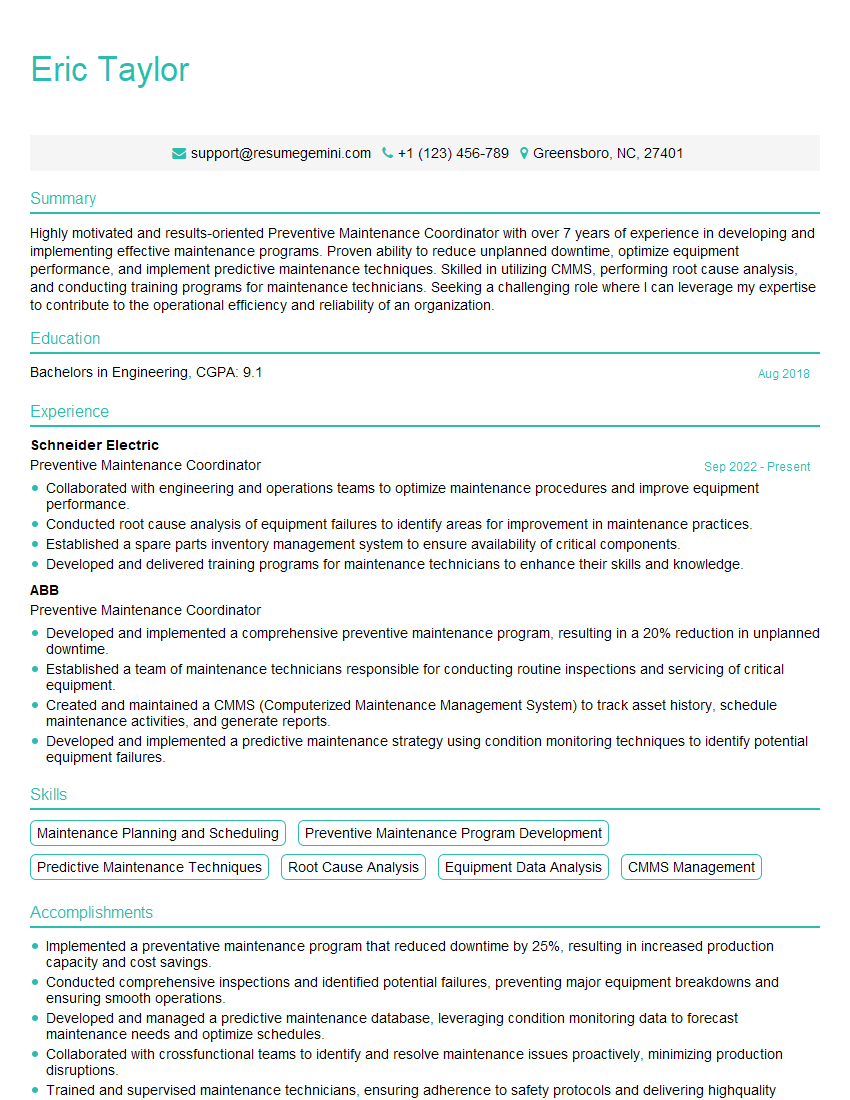

Eric Taylor

Preventive Maintenance Coordinator

Summary

Highly motivated and results-oriented Preventive Maintenance Coordinator with over 7 years of experience in developing and implementing effective maintenance programs. Proven ability to reduce unplanned downtime, optimize equipment performance, and implement predictive maintenance techniques. Skilled in utilizing CMMS, performing root cause analysis, and conducting training programs for maintenance technicians. Seeking a challenging role where I can leverage my expertise to contribute to the operational efficiency and reliability of an organization.

Education

Bachelors in Engineering

August 2018

Skills

- Maintenance Planning and Scheduling

- Preventive Maintenance Program Development

- Predictive Maintenance Techniques

- Root Cause Analysis

- Equipment Data Analysis

- CMMS Management

Work Experience

Preventive Maintenance Coordinator

- Collaborated with engineering and operations teams to optimize maintenance procedures and improve equipment performance.

- Conducted root cause analysis of equipment failures to identify areas for improvement in maintenance practices.

- Established a spare parts inventory management system to ensure availability of critical components.

- Developed and delivered training programs for maintenance technicians to enhance their skills and knowledge.

Preventive Maintenance Coordinator

- Developed and implemented a comprehensive preventive maintenance program, resulting in a 20% reduction in unplanned downtime.

- Established a team of maintenance technicians responsible for conducting routine inspections and servicing of critical equipment.

- Created and maintained a CMMS (Computerized Maintenance Management System) to track asset history, schedule maintenance activities, and generate reports.

- Developed and implemented a predictive maintenance strategy using condition monitoring techniques to identify potential equipment failures.

Accomplishments

- Implemented a preventative maintenance program that reduced downtime by 25%, resulting in increased production capacity and cost savings.

- Conducted comprehensive inspections and identified potential failures, preventing major equipment breakdowns and ensuring smooth operations.

- Developed and managed a predictive maintenance database, leveraging condition monitoring data to forecast maintenance needs and optimize schedules.

- Collaborated with crossfunctional teams to identify and resolve maintenance issues proactively, minimizing production disruptions.

- Trained and supervised maintenance technicians, ensuring adherence to safety protocols and delivering highquality maintenance services.

Awards

- Received the Preventive Maintenance Excellence Award for outstanding contributions in maintaining equipment performance and reliability.

Certificates

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Preventive Maintenance Manager (CPMM)

- Certified Maintenance Manager (CMM)

- Certified Maintenance and Reliability Technician (CMRT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Preventive Maintenance Coordinator

- Quantify your accomplishments by providing specific metrics and results.

- Highlight your expertise in utilizing CMMS and various maintenance techniques.

- Showcase your ability to collaborate effectively with cross-functional teams.

- Emphasize your commitment to continuous improvement and professional development.

- Tailor your resume to each job application, highlighting the skills and experience most relevant to the specific position.

Essential Experience Highlights for a Strong Preventive Maintenance Coordinator Resume

- Developed and executed a comprehensive preventive maintenance program that reduced unplanned downtime by 20%.

- Supervised a team of maintenance technicians accountable for routine inspections and servicing of mission-critical equipment.

- Managed a CMMS to monitor asset history, schedule maintenance activities, and create insightful reports.

- Implemented predictive maintenance strategies using condition monitoring techniques to proactively identify potential equipment failures.

- Collaborated closely with engineering and operations teams to refine maintenance procedures and elevate equipment performance.

- Performed thorough root cause analysis of equipment failures to ascertain areas for improvement in maintenance practices.

- Established a spare parts inventory management system to guarantee the availability of critical components.

Frequently Asked Questions (FAQ’s) For Preventive Maintenance Coordinator

What is the primary role of a Preventive Maintenance Coordinator?

The Preventive Maintenance Coordinator is responsible for developing, implementing, and managing preventive maintenance programs to minimize unplanned downtime, optimize equipment performance, and ensure the efficient operation of an organization’s assets.

What skills are essential for a Preventive Maintenance Coordinator?

A successful Preventive Maintenance Coordinator should possess technical knowledge in maintenance planning and scheduling, preventive maintenance program development, predictive maintenance techniques, root cause analysis, equipment data analysis, and CMMS management.

What are the key responsibilities of a Preventive Maintenance Coordinator?

Key responsibilities include developing and executing preventive maintenance programs, supervising maintenance teams, managing CMMS, implementing predictive maintenance strategies, collaborating with engineering and operations teams, performing root cause analysis, and establishing spare parts inventory management systems.

What industries employ Preventive Maintenance Coordinators?

Preventive Maintenance Coordinators are employed in a wide range of industries, including manufacturing, energy, utilities, transportation, and healthcare.

What is the career path for a Preventive Maintenance Coordinator?

Preventive Maintenance Coordinators can advance to roles such as Maintenance Manager, Reliability Engineer, or Plant Engineer. With further experience and education, they may also pursue leadership positions in maintenance and operations.

What are the educational requirements for a Preventive Maintenance Coordinator?

While there is no specific degree requirement, many Preventive Maintenance Coordinators hold a Bachelor’s degree in Engineering, Industrial Maintenance, or a related field.

What certifications are beneficial for a Preventive Maintenance Coordinator?

Relevant certifications include Certified Maintenance and Reliability Professional (CMRP), Certified Maintenance Manager (CMM), and Certified Predictive Maintenance Analyst (CPMA).