Are you a seasoned Printed Circuit Board Panels Plater seeking a new career path? Discover our professionally built Printed Circuit Board Panels Plater Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

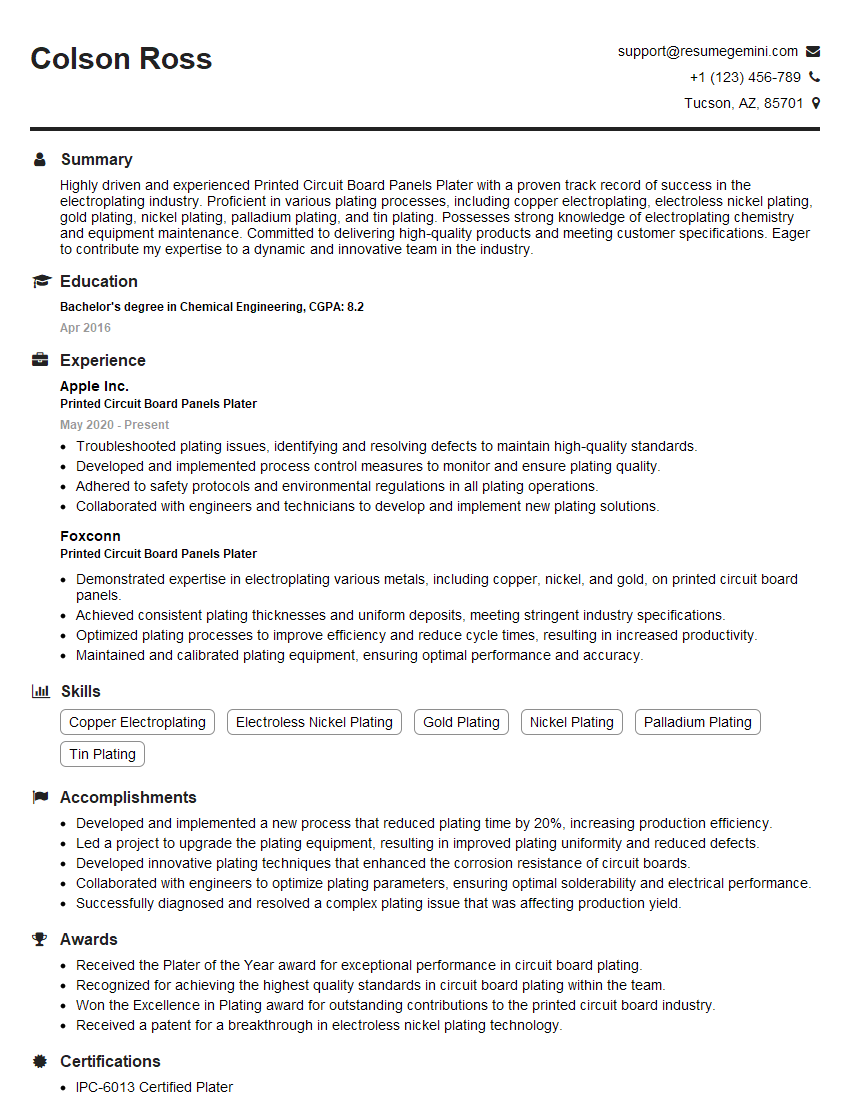

Colson Ross

Printed Circuit Board Panels Plater

Summary

Highly driven and experienced Printed Circuit Board Panels Plater with a proven track record of success in the electroplating industry. Proficient in various plating processes, including copper electroplating, electroless nickel plating, gold plating, nickel plating, palladium plating, and tin plating. Possesses strong knowledge of electroplating chemistry and equipment maintenance. Committed to delivering high-quality products and meeting customer specifications. Eager to contribute my expertise to a dynamic and innovative team in the industry.

Education

Bachelor’s degree in Chemical Engineering

April 2016

Skills

- Copper Electroplating

- Electroless Nickel Plating

- Gold Plating

- Nickel Plating

- Palladium Plating

- Tin Plating

Work Experience

Printed Circuit Board Panels Plater

- Troubleshooted plating issues, identifying and resolving defects to maintain high-quality standards.

- Developed and implemented process control measures to monitor and ensure plating quality.

- Adhered to safety protocols and environmental regulations in all plating operations.

- Collaborated with engineers and technicians to develop and implement new plating solutions.

Printed Circuit Board Panels Plater

- Demonstrated expertise in electroplating various metals, including copper, nickel, and gold, on printed circuit board panels.

- Achieved consistent plating thicknesses and uniform deposits, meeting stringent industry specifications.

- Optimized plating processes to improve efficiency and reduce cycle times, resulting in increased productivity.

- Maintained and calibrated plating equipment, ensuring optimal performance and accuracy.

Accomplishments

- Developed and implemented a new process that reduced plating time by 20%, increasing production efficiency.

- Led a project to upgrade the plating equipment, resulting in improved plating uniformity and reduced defects.

- Developed innovative plating techniques that enhanced the corrosion resistance of circuit boards.

- Collaborated with engineers to optimize plating parameters, ensuring optimal solderability and electrical performance.

- Successfully diagnosed and resolved a complex plating issue that was affecting production yield.

Awards

- Received the Plater of the Year award for exceptional performance in circuit board plating.

- Recognized for achieving the highest quality standards in circuit board plating within the team.

- Won the Excellence in Plating award for outstanding contributions to the printed circuit board industry.

- Received a patent for a breakthrough in electroless nickel plating technology.

Certificates

- IPC-6013 Certified Plater

- IPC-6012 Certified Circuit Board Inspector

- IPC-6011 Certified Solderer

- IPC-7711 Certified Rework and Repair Technician

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Printed Circuit Board Panels Plater

- Highlight your technical skills and experience in various plating processes.

- Quantify your accomplishments and provide specific examples of how you have contributed to the success of previous organizations.

- Showcase your knowledge of electroplating chemistry and equipment maintenance.

- Emphasize your commitment to quality control and meeting customer specifications.

- Demonstrate your ability to work effectively in a team environment.

Essential Experience Highlights for a Strong Printed Circuit Board Panels Plater Resume

- Operate and maintain electroplating equipment, including plating tanks, rectifiers, and filtration systems.

- Prepare and control plating solutions, ensuring compliance with quality standards.

- Monitor and adjust process parameters, such as temperature, pH, and current density, to optimize plating quality.

- Troubleshoot and resolve plating issues, such as poor adhesion, surface defects, and contamination.

- Perform quality control inspections and testing to ensure the production of defect-free printed circuit boards.

- Collaborate with engineering and production teams to develop and implement process improvements.

Frequently Asked Questions (FAQ’s) For Printed Circuit Board Panels Plater

What are the key skills required to be a successful Printed Circuit Board Panels Plater?

The key skills required for a Printed Circuit Board Panels Plater include a thorough understanding of electroplating chemistry, proficiency in various plating processes, expertise in equipment maintenance, strong analytical and problem-solving abilities, and a commitment to quality control.

What are the career prospects for Printed Circuit Board Panels Platers?

Printed Circuit Board Panels Platers are in high demand due to the growing electronics industry. With experience and expertise, they can advance to supervisory or management roles, specialize in specific plating processes, or pursue research and development opportunities.

What are the educational requirements to become a Printed Circuit Board Panels Plater?

While a high school diploma or equivalent qualification is typically sufficient, many employers prefer candidates with a Bachelor’s degree in Chemical Engineering, Materials Science, or a related field. Certifications in electroplating or related areas are also beneficial.

What is the work environment of a Printed Circuit Board Panels Plater like?

Printed Circuit Board Panels Platers typically work in industrial settings, such as electroplating shops or manufacturing facilities. They may be exposed to chemicals and fumes, so proper safety precautions and protective gear are essential.

How can I prepare for a career as a Printed Circuit Board Panels Plater?

To prepare for a career as a Printed Circuit Board Panels Plater, you can obtain a relevant degree or certification, gain hands-on experience through internships or apprenticeships, stay up-to-date with industry trends and advancements, and develop strong communication and teamwork skills.

What are the safety precautions that Printed Circuit Board Panels Platers must follow?

Printed Circuit Board Panels Platers must adhere to strict safety protocols, including proper handling and disposal of chemicals, wearing appropriate protective gear, maintaining a clean and organized work area, and following established operating procedures.