Are you a seasoned Printed Circuit Board Reworker seeking a new career path? Discover our professionally built Printed Circuit Board Reworker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

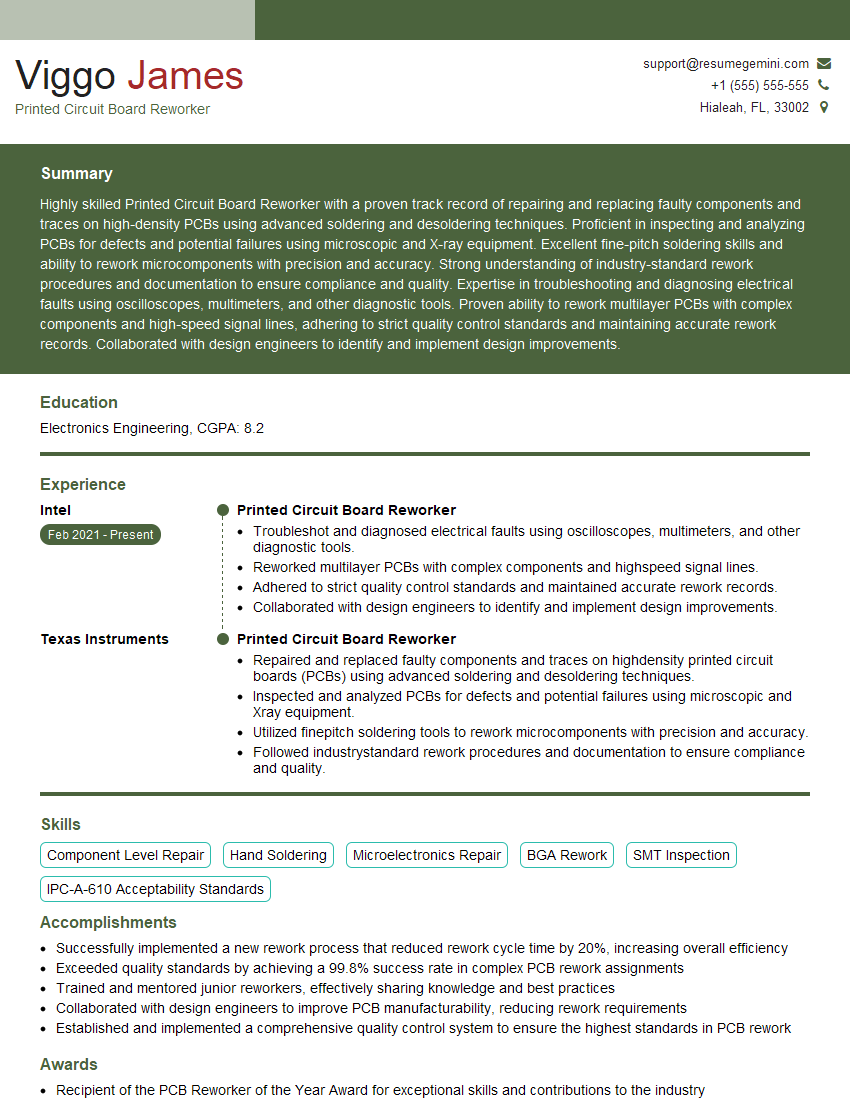

Viggo James

Printed Circuit Board Reworker

Summary

Highly skilled Printed Circuit Board Reworker with a proven track record of repairing and replacing faulty components and traces on high-density PCBs using advanced soldering and desoldering techniques. Proficient in inspecting and analyzing PCBs for defects and potential failures using microscopic and X-ray equipment. Excellent fine-pitch soldering skills and ability to rework microcomponents with precision and accuracy. Strong understanding of industry-standard rework procedures and documentation to ensure compliance and quality. Expertise in troubleshooting and diagnosing electrical faults using oscilloscopes, multimeters, and other diagnostic tools. Proven ability to rework multilayer PCBs with complex components and high-speed signal lines, adhering to strict quality control standards and maintaining accurate rework records. Collaborated with design engineers to identify and implement design improvements.

Education

Electronics Engineering

January 2017

Skills

- Component Level Repair

- Hand Soldering

- Microelectronics Repair

- BGA Rework

- SMT Inspection

- IPC-A-610 Acceptability Standards

Work Experience

Printed Circuit Board Reworker

- Troubleshot and diagnosed electrical faults using oscilloscopes, multimeters, and other diagnostic tools.

- Reworked multilayer PCBs with complex components and highspeed signal lines.

- Adhered to strict quality control standards and maintained accurate rework records.

- Collaborated with design engineers to identify and implement design improvements.

Printed Circuit Board Reworker

- Repaired and replaced faulty components and traces on highdensity printed circuit boards (PCBs) using advanced soldering and desoldering techniques.

- Inspected and analyzed PCBs for defects and potential failures using microscopic and Xray equipment.

- Utilized finepitch soldering tools to rework microcomponents with precision and accuracy.

- Followed industrystandard rework procedures and documentation to ensure compliance and quality.

Accomplishments

- Successfully implemented a new rework process that reduced rework cycle time by 20%, increasing overall efficiency

- Exceeded quality standards by achieving a 99.8% success rate in complex PCB rework assignments

- Trained and mentored junior reworkers, effectively sharing knowledge and best practices

- Collaborated with design engineers to improve PCB manufacturability, reducing rework requirements

- Established and implemented a comprehensive quality control system to ensure the highest standards in PCB rework

Awards

- Recipient of the PCB Reworker of the Year Award for exceptional skills and contributions to the industry

- Recognized for outstanding performance in PCB rework, receiving the Presidents Award for Excellence

- Received a Special Recognition Award for developing and implementing an innovative PCB rework technique

- Nominated for the Industry Achievement Award for contributions to the advancement of PCB rework technologies

Certificates

- IPC J-STD-001 Solder Joint Inspection

- IPC-620 Certified Solder Joint Technician

- ESD Safety and Control Certification

- SMTA Certified Process Technician (CPT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Printed Circuit Board Reworker

- Highlight your expertise in advanced soldering and desoldering techniques.

- Showcase your skills in inspecting and analyzing PCBs for defects using microscopic and X-ray equipment.

- Emphasize your ability to rework microcomponents with precision and accuracy using fine-pitch soldering tools.

- Demonstrate your understanding of industry-standard rework procedures and documentation.

- Provide specific examples of troubleshooting and diagnosing electrical faults using oscilloscopes, multimeters, and other diagnostic tools.

Essential Experience Highlights for a Strong Printed Circuit Board Reworker Resume

- Repairing and replacing faulty components and traces on high-density PCBs using advanced soldering and desoldering techniques.

- Inspecting and analyzing PCBs for defects and potential failures using microscopic and X-ray equipment.

- Utilizing fine-pitch soldering tools to rework microcomponents with precision and accuracy.

- Following industry-standard rework procedures and documentation to ensure compliance and quality.

- Troubleshooting and diagnosing electrical faults using oscilloscopes, multimeters, and other diagnostic tools.

- Reworking multilayer PCBs with complex components and high-speed signal lines.

Frequently Asked Questions (FAQ’s) For Printed Circuit Board Reworker

What are the key skills required for a Printed Circuit Board Reworker?

The key skills required for a Printed Circuit Board Reworker include advanced soldering and desoldering techniques, PCB inspection and analysis, fine-pitch soldering, troubleshooting and diagnosing electrical faults, and adherence to industry-standard rework procedures.

What are the career prospects for a Printed Circuit Board Reworker?

Printed Circuit Board Reworkers are in high demand in the electronics industry. They can find employment in various sectors, including manufacturing, repair, and maintenance. With experience and additional training, they can advance to supervisory or management roles.

What are the educational requirements for a Printed Circuit Board Reworker?

Most Printed Circuit Board Reworkers have a high school diploma or equivalent. They may also have some college education in electronics or a related field. Some employers may prefer candidates with military experience in electronics repair.

What is the work environment like for a Printed Circuit Board Reworker?

Printed Circuit Board Reworkers typically work in clean, well-lit environments. They may spend long periods sitting or standing at a workbench, using fine tools and equipment to repair PCBs. They may also be exposed to fumes and chemicals used in soldering and desoldering.

What are the safety precautions that a Printed Circuit Board Reworker should take?

Printed Circuit Board Reworkers should take precautions to avoid electrical shock, burns, and eye injuries. They should wear appropriate safety gear, including safety glasses, gloves, and a lab coat. They should also be aware of the potential hazards of the chemicals used in soldering and desoldering.

What are the challenges faced by a Printed Circuit Board Reworker?

Printed Circuit Board Reworkers may face challenges when working with complex PCBs, fine-pitch components, or high-speed signal lines. They may also need to troubleshoot and diagnose electrical faults, which can be time-consuming and difficult.