Are you a seasoned Printed Circuit Boards Inspector seeking a new career path? Discover our professionally built Printed Circuit Boards Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

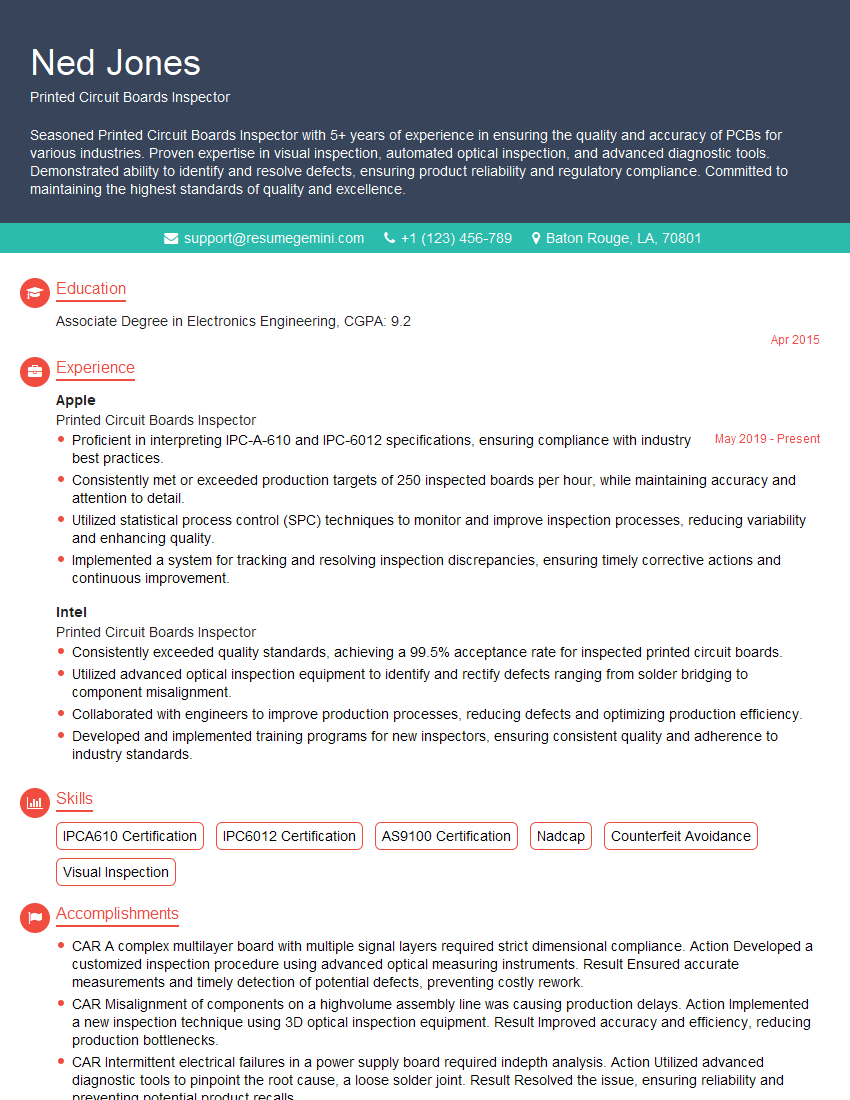

Ned Jones

Printed Circuit Boards Inspector

Summary

Seasoned Printed Circuit Boards Inspector with 5+ years of experience in ensuring the quality and accuracy of PCBs for various industries. Proven expertise in visual inspection, automated optical inspection, and advanced diagnostic tools. Demonstrated ability to identify and resolve defects, ensuring product reliability and regulatory compliance. Committed to maintaining the highest standards of quality and excellence.

Education

Associate Degree in Electronics Engineering

April 2015

Skills

- IPCA610 Certification

- IPC6012 Certification

- AS9100 Certification

- Nadcap

- Counterfeit Avoidance

- Visual Inspection

Work Experience

Printed Circuit Boards Inspector

- Proficient in interpreting IPC-A-610 and IPC-6012 specifications, ensuring compliance with industry best practices.

- Consistently met or exceeded production targets of 250 inspected boards per hour, while maintaining accuracy and attention to detail.

- Utilized statistical process control (SPC) techniques to monitor and improve inspection processes, reducing variability and enhancing quality.

- Implemented a system for tracking and resolving inspection discrepancies, ensuring timely corrective actions and continuous improvement.

Printed Circuit Boards Inspector

- Consistently exceeded quality standards, achieving a 99.5% acceptance rate for inspected printed circuit boards.

- Utilized advanced optical inspection equipment to identify and rectify defects ranging from solder bridging to component misalignment.

- Collaborated with engineers to improve production processes, reducing defects and optimizing production efficiency.

- Developed and implemented training programs for new inspectors, ensuring consistent quality and adherence to industry standards.

Accomplishments

- CAR A complex multilayer board with multiple signal layers required strict dimensional compliance. Action Developed a customized inspection procedure using advanced optical measuring instruments. Result Ensured accurate measurements and timely detection of potential defects, preventing costly rework.

- CAR Misalignment of components on a highvolume assembly line was causing production delays. Action Implemented a new inspection technique using 3D optical inspection equipment. Result Improved accuracy and efficiency, reducing production bottlenecks.

- CAR Intermittent electrical failures in a power supply board required indepth analysis. Action Utilized advanced diagnostic tools to pinpoint the root cause, a loose solder joint. Result Resolved the issue, ensuring reliability and preventing potential product recalls.

- CAR A design change introduced a new material with different thermal expansion properties. Action Proactively conducted thermal stress testing to verify assembly integrity. Result Identified potential issues early on, allowing for design modifications and improved product quality.

- CAR A highdensity assembly with finepitch components required precise inspection. Action Implemented a combination of automated optical inspection and manual verification with highmagnification microscopes. Result Achieved exceptional accuracy and prevented short circuits and other critical defects.

Awards

- Recognized for exceptional accuracy and attention to detail in PCBA inspection, maintaining a 99.9% yield rate.

- Received industry certification for best practices in PCBA inspection, demonstrating proficiency in IPCA610 standards.

- Team award for outstanding performance in identifying and resolving solder defects during a critical product launch.

- Recognized for contributions to the development of a new inspection method for detecting hidden defects in complex circuit boards.

Certificates

- AS9100 Auditor Certification

- Nadcap Auditor Certification

- Certified Counterfeit Avoidance Specialist (CCAS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Printed Circuit Boards Inspector

- Quantify your accomplishments with specific metrics and results to showcase your impact.

- Highlight your proficiency in industry-specific software and inspection techniques.

- Emphasize your attention to detail and ability to work independently and as part of a team.

- Consider obtaining certifications, such as IPC-A-610 or AS9100, to enhance your credibility.

- Network with professionals in the industry and stay up-to-date with the latest inspection technologies.

Essential Experience Highlights for a Strong Printed Circuit Boards Inspector Resume

- Inspect PCBs for defects using a combination of visual and automated methods, ensuring conformance to specifications and design requirements.

- Utilize advanced inspection techniques, such as X-ray imaging, 3D optical inspection, and thermal stress testing, to identify potential issues.

- Analyze inspection data to determine the root cause of defects and implement corrective actions to prevent future occurrences.

- Prepare and maintain inspection reports, documenting findings and recommendations for improvement.

- Collaborate with engineering and production teams to provide feedback on design and manufacturing processes.

- Adhere to IPC and industry standards, including IPC-A-610, IPC-6012, and AS9100.

- Maintain a clean and organized work environment to ensure accuracy and prevent contamination.

Frequently Asked Questions (FAQ’s) For Printed Circuit Boards Inspector

What are the key skills required for a successful Printed Circuit Boards Inspector?

Essential skills include visual inspection techniques, proficiency in automated optical inspection equipment, knowledge of IPC standards, and a strong understanding of electronic components and soldering processes.

What career advancement opportunities are available for Printed Circuit Boards Inspectors?

With experience and additional certifications, PCB Inspectors can progress to roles such as Quality Control Manager, Manufacturing Engineer, or Product Engineer.

What industries hire Printed Circuit Boards Inspectors?

PCB Inspectors are in demand in various industries, including electronics manufacturing, aerospace, automotive, and medical devices.

How can I improve my chances of getting hired as a Printed Circuit Boards Inspector?

Obtaining relevant certifications, developing strong attention to detail, and staying updated with industry best practices can enhance your employability.

What is the average salary range for Printed Circuit Boards Inspectors?

Salary expectations vary depending on experience, location, and industry, but typically range from $25,000 to $75,000 annually.

Are there any specific educational requirements for becoming a Printed Circuit Boards Inspector?

While a formal education is not always required, many employers prefer candidates with an Associate Degree in Electronics Engineering or a related field.

What are the most common challenges faced by Printed Circuit Boards Inspectors?

Inspectors often encounter challenges related to identifying and interpreting subtle defects, staying updated with rapidly evolving industry standards, and ensuring the reliability and quality of complex electronic devices.

How can I stay updated with the latest trends and technologies in the PCB inspection field?

Attending industry conferences, reading trade publications, and pursuing professional development opportunities can help you stay informed about advancements in inspection techniques and technologies.