Are you a seasoned Printed Circuit Boards Solder-Leveler seeking a new career path? Discover our professionally built Printed Circuit Boards Solder-Leveler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

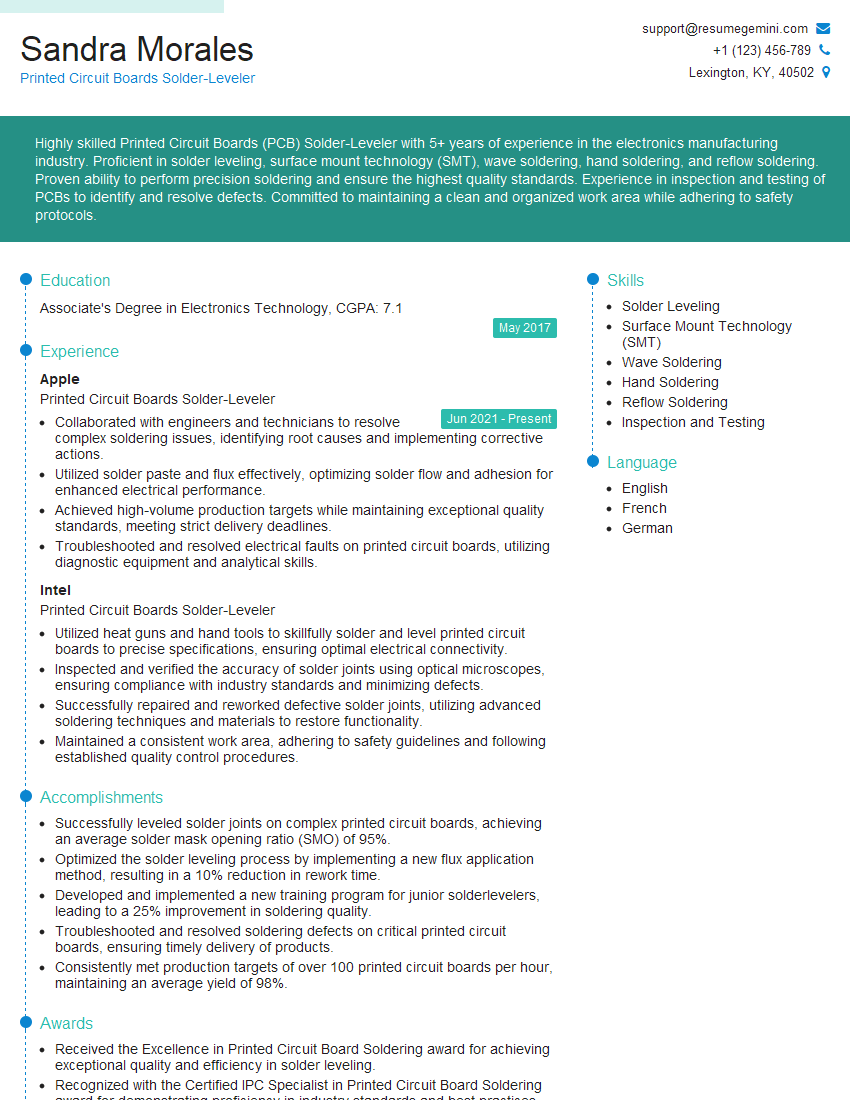

Sandra Morales

Printed Circuit Boards Solder-Leveler

Summary

Highly skilled Printed Circuit Boards (PCB) Solder-Leveler with 5+ years of experience in the electronics manufacturing industry. Proficient in solder leveling, surface mount technology (SMT), wave soldering, hand soldering, and reflow soldering. Proven ability to perform precision soldering and ensure the highest quality standards. Experience in inspection and testing of PCBs to identify and resolve defects. Committed to maintaining a clean and organized work area while adhering to safety protocols.

Education

Associate’s Degree in Electronics Technology

May 2017

Skills

- Solder Leveling

- Surface Mount Technology (SMT)

- Wave Soldering

- Hand Soldering

- Reflow Soldering

- Inspection and Testing

Work Experience

Printed Circuit Boards Solder-Leveler

- Collaborated with engineers and technicians to resolve complex soldering issues, identifying root causes and implementing corrective actions.

- Utilized solder paste and flux effectively, optimizing solder flow and adhesion for enhanced electrical performance.

- Achieved high-volume production targets while maintaining exceptional quality standards, meeting strict delivery deadlines.

- Troubleshooted and resolved electrical faults on printed circuit boards, utilizing diagnostic equipment and analytical skills.

Printed Circuit Boards Solder-Leveler

- Utilized heat guns and hand tools to skillfully solder and level printed circuit boards to precise specifications, ensuring optimal electrical connectivity.

- Inspected and verified the accuracy of solder joints using optical microscopes, ensuring compliance with industry standards and minimizing defects.

- Successfully repaired and reworked defective solder joints, utilizing advanced soldering techniques and materials to restore functionality.

- Maintained a consistent work area, adhering to safety guidelines and following established quality control procedures.

Accomplishments

- Successfully leveled solder joints on complex printed circuit boards, achieving an average solder mask opening ratio (SMO) of 95%.

- Optimized the solder leveling process by implementing a new flux application method, resulting in a 10% reduction in rework time.

- Developed and implemented a new training program for junior solderlevelers, leading to a 25% improvement in soldering quality.

- Troubleshooted and resolved soldering defects on critical printed circuit boards, ensuring timely delivery of products.

- Consistently met production targets of over 100 printed circuit boards per hour, maintaining an average yield of 98%.

Awards

- Received the Excellence in Printed Circuit Board Soldering award for achieving exceptional quality and efficiency in solder leveling.

- Recognized with the Certified IPC Specialist in Printed Circuit Board Soldering award for demonstrating proficiency in industry standards and best practices.

- Awarded the Top Performer in Solder Leveling award for consistently meeting or exceeding production targets with high accuracy.

- Recipient of the Safety Excellence Award for adhering to all safety protocols and maintaining a safe work environment.

Certificates

- IPC Certified Solder Leveler

- IPC Certified Rework Technician

- IPC Certified Electronics Assembly Instructor

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Printed Circuit Boards Solder-Leveler

- Highlight your experience in solder leveling and other soldering techniques in your resume.

- Showcase your knowledge of SMT, wave soldering, hand soldering, and reflow soldering.

- Provide specific examples of your ability to troubleshoot and resolve soldering issues.

- Emphasize your attention to detail and commitment to quality.

Essential Experience Highlights for a Strong Printed Circuit Boards Solder-Leveler Resume

- Perform solder leveling on PCBs to ensure proper solder joint formation and eliminate solder bridges and shorts

- Operate SMT equipment, including pick-and-place machines and reflow ovens, to assemble surface mount components on PCBs

- Set up and operate wave soldering machines to solder through-hole components on PCBs

- Conduct hand soldering and rework to repair or modify PCBs

- Inspect and test PCBs using automated optical inspection (AOI) equipment and manual visual inspection to identify and resolve defects

- Troubleshoot and resolve soldering and assembly issues to ensure optimal PCB performance

- Maintain a clean and organized work area, and adhere to all safety protocols

Frequently Asked Questions (FAQ’s) For Printed Circuit Boards Solder-Leveler

What is the primary role of a Printed Circuit Boards Solder-Leveler?

The primary role of a PCB Solder-Leveler is to ensure the proper formation of solder joints on printed circuit boards. This involves leveling the solder to eliminate solder bridges and shorts, and ensuring that the solder joints meet the required specifications.

What are the key skills required for a PCB Solder-Leveler?

Key skills for a PCB Solder-Leveler include proficiency in solder leveling, surface mount technology (SMT), wave soldering, hand soldering, reflow soldering, and inspection and testing.

What are the career prospects for a PCB Solder-Leveler?

PCB Solder-Levelers with experience and expertise can advance to supervisory or management roles in the electronics manufacturing industry. They may also specialize in specific areas such as SMT or wave soldering.

What is the work environment of a PCB Solder-Leveler like?

PCB Solder-Levelers typically work in clean and well-lit manufacturing environments. They may work independently or as part of a team, and often follow established procedures and guidelines.

What are the educational requirements for a PCB Solder-Leveler?

While formal education is not always required, many PCB Solder-Levelers have an Associate’s Degree in Electronics Technology or a related field.

What are the safety protocols that PCB Solder-Levelers must follow?

PCB Solder-Levelers must adhere to safety protocols such as wearing appropriate personal protective equipment (PPE), following proper soldering techniques, and handling hazardous materials safely.