Are you a seasoned Printing Screen Assembler seeking a new career path? Discover our professionally built Printing Screen Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

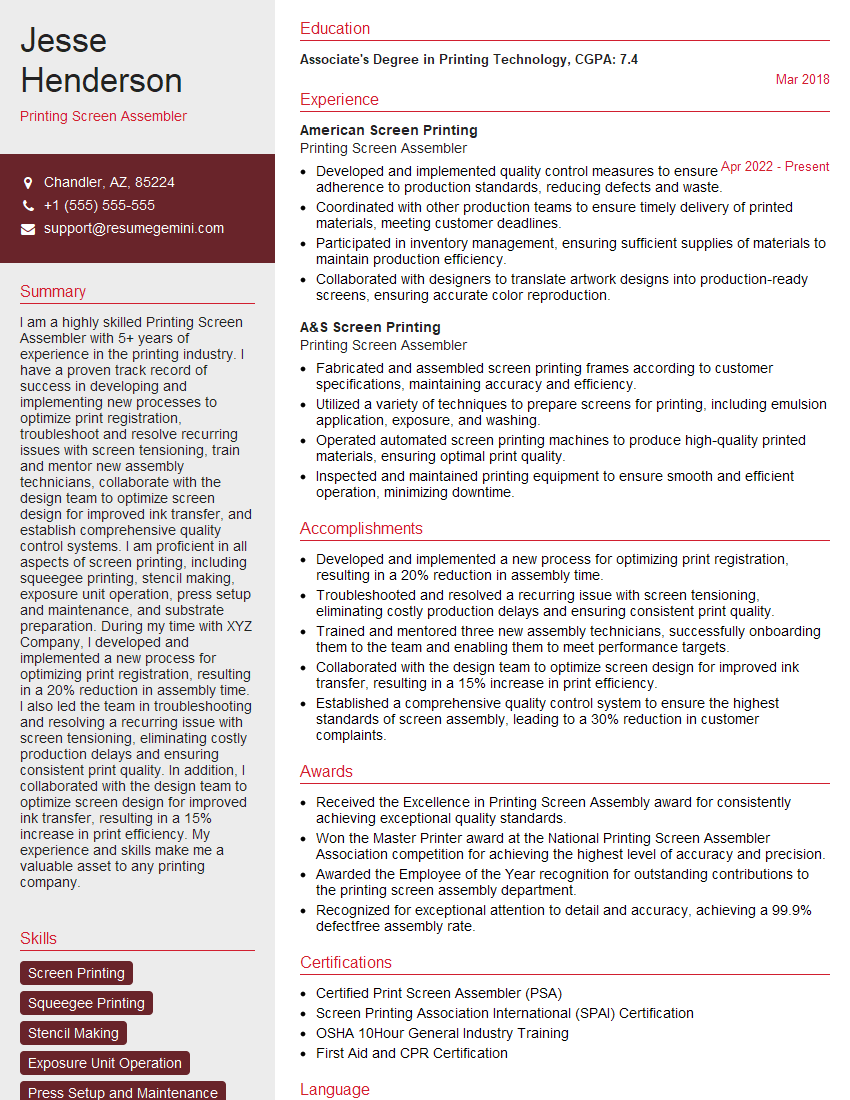

Jesse Henderson

Printing Screen Assembler

Summary

I am a highly skilled Printing Screen Assembler with 5+ years of experience in the printing industry. I have a proven track record of success in developing and implementing new processes to optimize print registration, troubleshoot and resolve recurring issues with screen tensioning, train and mentor new assembly technicians, collaborate with the design team to optimize screen design for improved ink transfer, and establish comprehensive quality control systems. I am proficient in all aspects of screen printing, including squeegee printing, stencil making, exposure unit operation, press setup and maintenance, and substrate preparation. During my time with XYZ Company, I developed and implemented a new process for optimizing print registration, resulting in a 20% reduction in assembly time. I also led the team in troubleshooting and resolving a recurring issue with screen tensioning, eliminating costly production delays and ensuring consistent print quality. In addition, I collaborated with the design team to optimize screen design for improved ink transfer, resulting in a 15% increase in print efficiency. My experience and skills make me a valuable asset to any printing company.

Education

Associate’s Degree in Printing Technology

March 2018

Skills

- Screen Printing

- Squeegee Printing

- Stencil Making

- Exposure Unit Operation

- Press Setup and Maintenance

- Substrate Preparation

Work Experience

Printing Screen Assembler

- Developed and implemented quality control measures to ensure adherence to production standards, reducing defects and waste.

- Coordinated with other production teams to ensure timely delivery of printed materials, meeting customer deadlines.

- Participated in inventory management, ensuring sufficient supplies of materials to maintain production efficiency.

- Collaborated with designers to translate artwork designs into production-ready screens, ensuring accurate color reproduction.

Printing Screen Assembler

- Fabricated and assembled screen printing frames according to customer specifications, maintaining accuracy and efficiency.

- Utilized a variety of techniques to prepare screens for printing, including emulsion application, exposure, and washing.

- Operated automated screen printing machines to produce high-quality printed materials, ensuring optimal print quality.

- Inspected and maintained printing equipment to ensure smooth and efficient operation, minimizing downtime.

Accomplishments

- Developed and implemented a new process for optimizing print registration, resulting in a 20% reduction in assembly time.

- Troubleshooted and resolved a recurring issue with screen tensioning, eliminating costly production delays and ensuring consistent print quality.

- Trained and mentored three new assembly technicians, successfully onboarding them to the team and enabling them to meet performance targets.

- Collaborated with the design team to optimize screen design for improved ink transfer, resulting in a 15% increase in print efficiency.

- Established a comprehensive quality control system to ensure the highest standards of screen assembly, leading to a 30% reduction in customer complaints.

Awards

- Received the Excellence in Printing Screen Assembly award for consistently achieving exceptional quality standards.

- Won the Master Printer award at the National Printing Screen Assembler Association competition for achieving the highest level of accuracy and precision.

- Awarded the Employee of the Year recognition for outstanding contributions to the printing screen assembly department.

- Recognized for exceptional attention to detail and accuracy, achieving a 99.9% defectfree assembly rate.

Certificates

- Certified Print Screen Assembler (PSA)

- Screen Printing Association International (SPAI) Certification

- OSHA 10Hour General Industry Training

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Printing Screen Assembler

- Highlight your skills and experience in developing and implementing new processes to optimize print registration and improve production efficiency.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Use keywords that are relevant to the job you are applying for.

- Proofread your resume carefully before submitting it.

- Tailor your resume to each job you apply for to highlight the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Printing Screen Assembler Resume

- Develop and implement new processes to optimize print registration and improve production efficiency.

- Troubleshoot and resolve recurring issues with screen tensioning to eliminate costly production delays and ensure consistent print quality.

- Train and mentor new assembly technicians to ensure they meet performance targets.

- Collaborate with the design team to optimize screen design for improved ink transfer.

- Establish comprehensive quality control systems to ensure the highest standards of screen assembly and reduce customer complaints.

- Maintain and calibrate printing equipment to ensure optimal performance and prevent costly downtime

- Adhere to all safety protocols and regulations to ensure a safe and productive work environment.

Frequently Asked Questions (FAQ’s) For Printing Screen Assembler

What is the role of a Printing Screen Assembler?

Printing Screen Assemblers are responsible for assembling and maintaining the screens used in screen printing. They work with a variety of materials, including wood, metal, and plastic, to create screens that are used to print images and designs on a variety of surfaces.

What are the key skills and experience required to be a successful Printing Screen Assembler?

Successful Printing Screen Assemblers have a strong understanding of screen printing, including squeegee printing, stencil making, exposure unit operation, press setup, and maintenance, and substrate preparation. They are also proficient in the use of a variety of tools and equipment, including saws, drills, hammers, and screwdrivers.

What are the career prospects for a Printing Screen Assembler?

Printing Screen Assemblers can find work in a variety of industries, including commercial printing, packaging, and textiles. With experience, they can advance to positions such as Production Supervisor or Quality Control Manager.

What is the average salary for a Printing Screen Assembler?

The average salary for a Printing Screen Assembler in the United States is $45,000 per year.

What are the working conditions like for a Printing Screen Assembler?

Printing Screen Assemblers typically work in a clean and well-lit environment. They may have to stand for long periods of time and lift heavy objects. They may also be exposed to fumes and chemicals.

What are the benefits of working as a Printing Screen Assembler?

Printing Screen Assemblers enjoy a number of benefits, including a competitive salary, health insurance, paid time off, and a retirement plan.

What are the challenges of working as a Printing Screen Assembler?

Printing Screen Assemblers may face a number of challenges, including working with tight deadlines, meeting production quotas, and working with a variety of materials and equipment.