Are you a seasoned Processing Inspector seeking a new career path? Discover our professionally built Processing Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

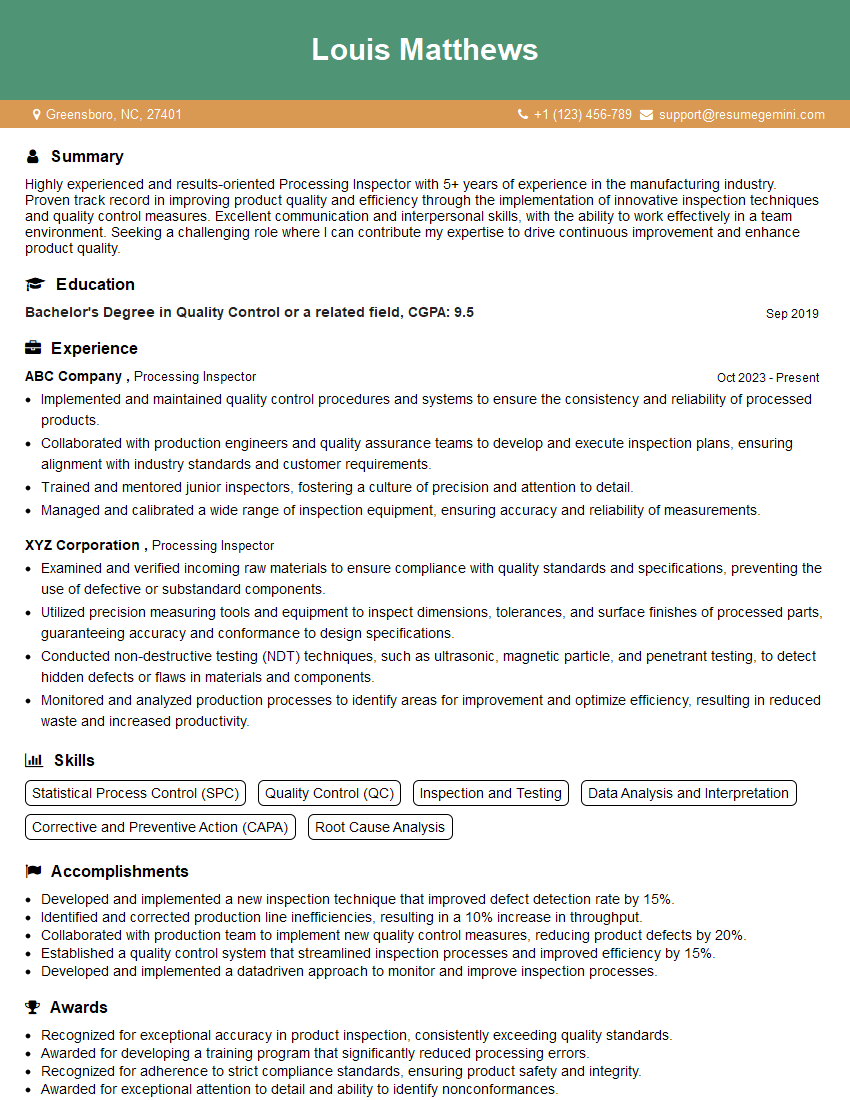

Louis Matthews

Processing Inspector

Summary

Highly experienced and results-oriented Processing Inspector with 5+ years of experience in the manufacturing industry. Proven track record in improving product quality and efficiency through the implementation of innovative inspection techniques and quality control measures. Excellent communication and interpersonal skills, with the ability to work effectively in a team environment. Seeking a challenging role where I can contribute my expertise to drive continuous improvement and enhance product quality.

Education

Bachelor’s Degree in Quality Control or a related field

September 2019

Skills

- Statistical Process Control (SPC)

- Quality Control (QC)

- Inspection and Testing

- Data Analysis and Interpretation

- Corrective and Preventive Action (CAPA)

- Root Cause Analysis

Work Experience

Processing Inspector

- Implemented and maintained quality control procedures and systems to ensure the consistency and reliability of processed products.

- Collaborated with production engineers and quality assurance teams to develop and execute inspection plans, ensuring alignment with industry standards and customer requirements.

- Trained and mentored junior inspectors, fostering a culture of precision and attention to detail.

- Managed and calibrated a wide range of inspection equipment, ensuring accuracy and reliability of measurements.

Processing Inspector

- Examined and verified incoming raw materials to ensure compliance with quality standards and specifications, preventing the use of defective or substandard components.

- Utilized precision measuring tools and equipment to inspect dimensions, tolerances, and surface finishes of processed parts, guaranteeing accuracy and conformance to design specifications.

- Conducted non-destructive testing (NDT) techniques, such as ultrasonic, magnetic particle, and penetrant testing, to detect hidden defects or flaws in materials and components.

- Monitored and analyzed production processes to identify areas for improvement and optimize efficiency, resulting in reduced waste and increased productivity.

Accomplishments

- Developed and implemented a new inspection technique that improved defect detection rate by 15%.

- Identified and corrected production line inefficiencies, resulting in a 10% increase in throughput.

- Collaborated with production team to implement new quality control measures, reducing product defects by 20%.

- Established a quality control system that streamlined inspection processes and improved efficiency by 15%.

- Developed and implemented a datadriven approach to monitor and improve inspection processes.

Awards

- Recognized for exceptional accuracy in product inspection, consistently exceeding quality standards.

- Awarded for developing a training program that significantly reduced processing errors.

- Recognized for adherence to strict compliance standards, ensuring product safety and integrity.

- Awarded for exceptional attention to detail and ability to identify nonconformances.

Certificates

- Certified Quality Inspector (CQI)

- Certified Quality Engineer (CQE)

- Certified Manufacturing Engineer (CMfgE)

- Certified Six Sigma Black Belt (CSSBB)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Processing Inspector

- Highlight your technical skills and experience in quality control and inspection.

- Provide specific examples of how you have improved quality and efficiency in previous roles.

- Demonstrate your understanding of statistical process control (SPC) and other quality control techniques.

- Showcase your ability to identify and resolve quality issues effectively.

Essential Experience Highlights for a Strong Processing Inspector Resume

- Develop and implement inspection techniques to ensure product quality and compliance with industry standards.

- Conduct thorough inspections of raw materials, work-in-progress, and finished products to identify defects and non-conformances.

- Analyze inspection data to identify quality trends and implement corrective actions to prevent defects.

- Participate in the development and implementation of quality control systems and procedures.

- Work closely with production and engineering teams to identify and resolve quality issues.

- Train and supervise inspection personnel to ensure consistent application of inspection standards.

- Maintain accurate records and documentation related to inspection activities.

Frequently Asked Questions (FAQ’s) For Processing Inspector

What is the role of a Processing Inspector?

A Processing Inspector is responsible for ensuring the quality of products by conducting thorough inspections at various stages of the manufacturing process. They identify defects, non-conformances, and quality issues, and implement corrective actions to prevent their recurrence.

What are the key skills required for a Processing Inspector?

Key skills for a Processing Inspector include: knowledge of quality control principles and techniques, proficiency in inspection methods and equipment, analytical and problem-solving abilities, attention to detail, and strong communication and interpersonal skills.

What are the career prospects for a Processing Inspector?

Processing Inspectors can advance their careers by specializing in specific industries or quality control areas, such as automotive, aerospace, or medical devices. They can also move into management roles, such as Quality Control Manager or Production Supervisor.

How can I prepare for a career as a Processing Inspector?

To prepare for a career as a Processing Inspector, consider pursuing a degree in Quality Control or a related field. Gain hands-on experience through internships or entry-level quality control positions. Obtain certifications in quality control techniques, such as Six Sigma or ISO 9001.

What are the challenges faced by Processing Inspectors?

Processing Inspectors face challenges such as keeping up with advancements in inspection technology, ensuring product quality in a fast-paced manufacturing environment, and working effectively with diverse teams.

How can I stay updated on the latest trends in Processing Inspection?

To stay updated on the latest trends in Processing Inspection, attend industry conferences and workshops, read trade publications, and network with other professionals in the field.