Are you a seasoned Production Controller seeking a new career path? Discover our professionally built Production Controller Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

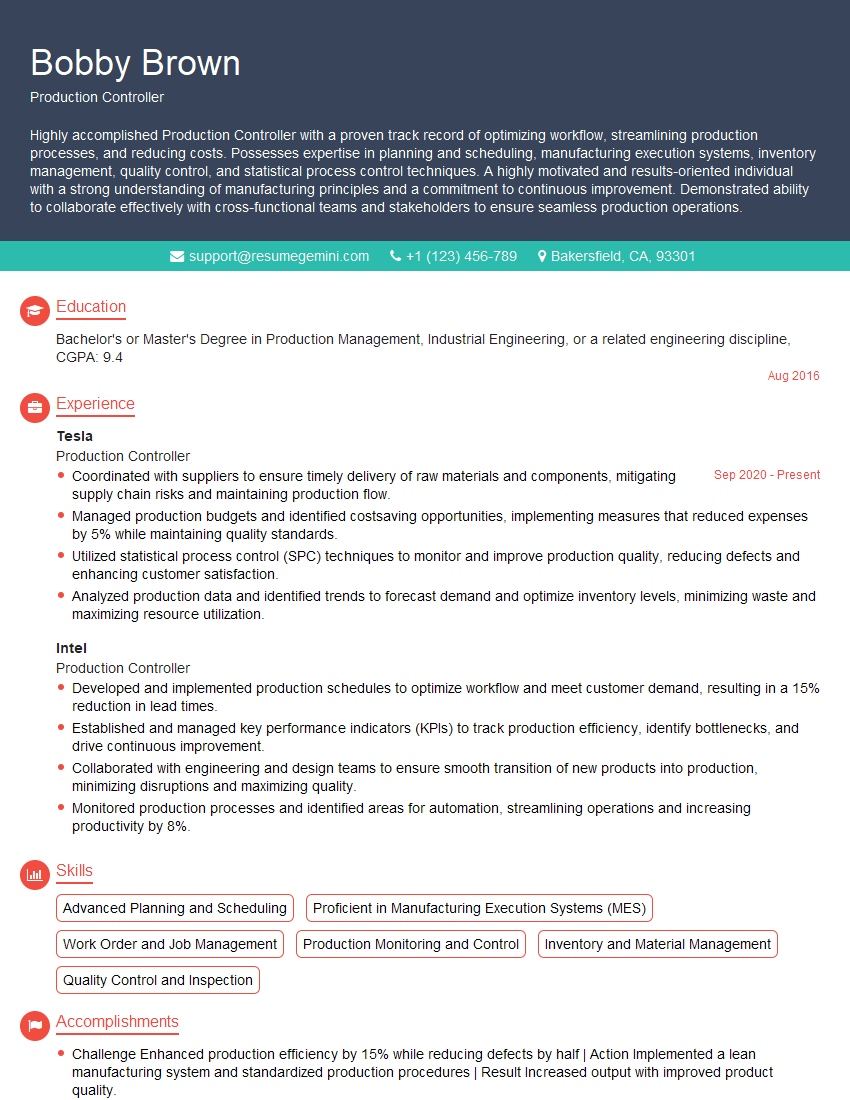

Bobby Brown

Production Controller

Summary

Highly accomplished Production Controller with a proven track record of optimizing workflow, streamlining production processes, and reducing costs. Possesses expertise in planning and scheduling, manufacturing execution systems, inventory management, quality control, and statistical process control techniques. A highly motivated and results-oriented individual with a strong understanding of manufacturing principles and a commitment to continuous improvement. Demonstrated ability to collaborate effectively with cross-functional teams and stakeholders to ensure seamless production operations.

Education

Bachelor’s or Master’s Degree in Production Management, Industrial Engineering, or a related engineering discipline

August 2016

Skills

- Advanced Planning and Scheduling

- Proficient in Manufacturing Execution Systems (MES)

- Work Order and Job Management

- Production Monitoring and Control

- Inventory and Material Management

- Quality Control and Inspection

Work Experience

Production Controller

- Coordinated with suppliers to ensure timely delivery of raw materials and components, mitigating supply chain risks and maintaining production flow.

- Managed production budgets and identified costsaving opportunities, implementing measures that reduced expenses by 5% while maintaining quality standards.

- Utilized statistical process control (SPC) techniques to monitor and improve production quality, reducing defects and enhancing customer satisfaction.

- Analyzed production data and identified trends to forecast demand and optimize inventory levels, minimizing waste and maximizing resource utilization.

Production Controller

- Developed and implemented production schedules to optimize workflow and meet customer demand, resulting in a 15% reduction in lead times.

- Established and managed key performance indicators (KPIs) to track production efficiency, identify bottlenecks, and drive continuous improvement.

- Collaborated with engineering and design teams to ensure smooth transition of new products into production, minimizing disruptions and maximizing quality.

- Monitored production processes and identified areas for automation, streamlining operations and increasing productivity by 8%.

Accomplishments

- Challenge Enhanced production efficiency by 15% while reducing defects by half | Action Implemented a lean manufacturing system and standardized production procedures | Result Increased output with improved product quality.

- Challenge Reduced production downtime by 20% | Action Analyzed production data to identify bottlenecks and implemented preventive maintenance schedules | Result Improved equipment reliability and minimized disruptions.

- Challenge Improved inventory management by 10% | Action Implemented a justintime inventory system and optimized warehouse layout | Result Reduced inventory carrying costs and improved production flow.

- Challenge Coordinated a largescale production transition with minimal disruption | Action Developed a comprehensive transition plan and communicated it effectively to stakeholders | Result Transitioned to a new product line seamlessly, maintaining production continuity.

- Challenge Implemented a new quality control system | Action Restructured inspection processes and trained staff on advanced quality techniques | Result Reduced product defects by 30% and improved customer satisfaction.

Awards

- Excellence in Production Management Award, recognized for outstanding contributions to optimizing production processes and exceeding quality standards.

- Top Performer Award for consistently surpassing production targets and maintaining exceptional accuracy levels.

- Innovation Award for developing a novel scheduling algorithm that optimized production planning.

- LEAN Six Sigma Black Belt Certification, demonstrating expertise in process improvement methodologies.

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Production Controller

- Quantify your accomplishments with specific metrics and data points to demonstrate your impact

- Highlight your proficiency in relevant software applications, such as manufacturing execution systems (MES), work order management systems, and statistical process control tools

- Emphasize your ability to collaborate effectively with cross-functional teams and stakeholders

- Showcase your understanding of lean manufacturing principles and continuous improvement methodologies

- Tailor your resume to each specific job description, highlighting the skills and experience most relevant to the role

Essential Experience Highlights for a Strong Production Controller Resume

- Develop and implement production schedules to optimize workflow and meet customer demand

- Establish and manage key performance indicators (KPIs) to track production efficiency, identify bottlenecks, and drive continuous improvement

- Collaborate with engineering and design teams to ensure smooth transition of new products into production, minimizing disruptions and maximizing quality

- Monitor production processes and identify areas for automation, streamlining operations and increasing productivity

- Coordinate with suppliers to ensure timely delivery of raw materials and components, mitigating supply chain risks and maintaining production flow

- Manage production budgets and identify cost-saving opportunities, implementing measures that reduce expenses while maintaining quality standards

- Utilize statistical process control (SPC) techniques to monitor and improve production quality, reducing defects and enhancing customer satisfaction

Frequently Asked Questions (FAQ’s) For Production Controller

What is the primary role of a Production Controller?

A Production Controller is responsible for planning, scheduling, and coordinating production activities to ensure that products are manufactured efficiently and cost-effectively, meeting customer demand and quality standards

What are the essential skills required for a Production Controller?

Essential skills for a Production Controller include advanced planning and scheduling, proficiency in manufacturing execution systems, work order and job management, production monitoring and control, inventory and material management, quality control and inspection, and a strong understanding of lean manufacturing principles

What is the career path for a Production Controller?

With experience and professional development, a Production Controller can advance to roles such as Production Manager, Operations Manager, or Plant Manager, assuming broader responsibilities for production operations and strategic decision-making

What are the typical industries that employ Production Controllers?

Production Controllers are employed in a wide range of industries, including automotive, aerospace, electronics, food and beverage, and pharmaceutical manufacturing, among others

How can I become a certified Production Controller?

There are several professional organizations that offer certifications for Production Controllers, such as the American Production and Inventory Control Society (APICS), which offers the Certified in Production and Inventory Management (CPIM) certification

What is the job outlook for Production Controllers?

The job outlook for Production Controllers is expected to be positive in the coming years, driven by the increasing demand for efficient and cost-effective manufacturing operations