Are you a seasoned Production Engineering Tooling Coordinator seeking a new career path? Discover our professionally built Production Engineering Tooling Coordinator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

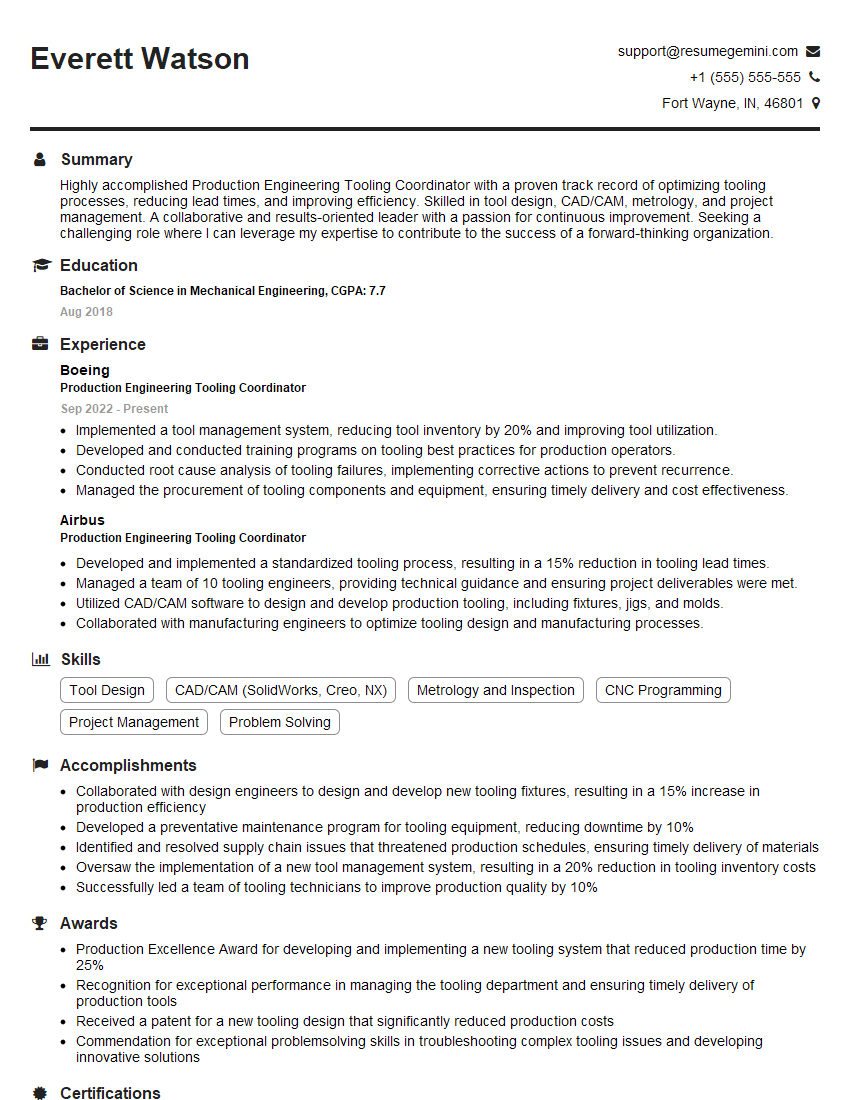

Everett Watson

Production Engineering Tooling Coordinator

Summary

Highly accomplished Production Engineering Tooling Coordinator with a proven track record of optimizing tooling processes, reducing lead times, and improving efficiency. Skilled in tool design, CAD/CAM, metrology, and project management. A collaborative and results-oriented leader with a passion for continuous improvement. Seeking a challenging role where I can leverage my expertise to contribute to the success of a forward-thinking organization.

Education

Bachelor of Science in Mechanical Engineering

August 2018

Skills

- Tool Design

- CAD/CAM (SolidWorks, Creo, NX)

- Metrology and Inspection

- CNC Programming

- Project Management

- Problem Solving

Work Experience

Production Engineering Tooling Coordinator

- Implemented a tool management system, reducing tool inventory by 20% and improving tool utilization.

- Developed and conducted training programs on tooling best practices for production operators.

- Conducted root cause analysis of tooling failures, implementing corrective actions to prevent recurrence.

- Managed the procurement of tooling components and equipment, ensuring timely delivery and cost effectiveness.

Production Engineering Tooling Coordinator

- Developed and implemented a standardized tooling process, resulting in a 15% reduction in tooling lead times.

- Managed a team of 10 tooling engineers, providing technical guidance and ensuring project deliverables were met.

- Utilized CAD/CAM software to design and develop production tooling, including fixtures, jigs, and molds.

- Collaborated with manufacturing engineers to optimize tooling design and manufacturing processes.

Accomplishments

- Collaborated with design engineers to design and develop new tooling fixtures, resulting in a 15% increase in production efficiency

- Developed a preventative maintenance program for tooling equipment, reducing downtime by 10%

- Identified and resolved supply chain issues that threatened production schedules, ensuring timely delivery of materials

- Oversaw the implementation of a new tool management system, resulting in a 20% reduction in tooling inventory costs

- Successfully led a team of tooling technicians to improve production quality by 10%

Awards

- Production Excellence Award for developing and implementing a new tooling system that reduced production time by 25%

- Recognition for exceptional performance in managing the tooling department and ensuring timely delivery of production tools

- Received a patent for a new tooling design that significantly reduced production costs

- Commendation for exceptional problemsolving skills in troubleshooting complex tooling issues and developing innovative solutions

Certificates

- CMfgT (Certified Manufacturing Technologist)

- CMMC (CMM Coordinator)

- CQT (Certified Quality Technician)

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Production Engineering Tooling Coordinator

- Highlight your technical skills and experience in tool design, CAD/CAM, and metrology.

- Quantify your accomplishments to demonstrate the impact of your work.

- Emphasize your leadership and project management abilities.

- Showcase your problem-solving and analytical skills.

- Demonstrate your commitment to continuous improvement and efficiency.

Essential Experience Highlights for a Strong Production Engineering Tooling Coordinator Resume

- Developed and implemented a standardized tooling process, resulting in a 15% reduction in tooling lead times.

- Managed a team of 10 tooling engineers, providing technical guidance and ensuring project deliverables were met.

- Utilized CAD/CAM software to design and develop production tooling, including fixtures, jigs, and molds.

- Collaborated with manufacturing engineers to optimize tooling design and manufacturing processes.

- Implemented a tool management system, reducing tool inventory by 20% and improving tool utilization.

- Developed and conducted training programs on tooling best practices for production operators.

- Conducted root cause analysis of tooling failures, implementing corrective actions to prevent recurrence.

Frequently Asked Questions (FAQ’s) For Production Engineering Tooling Coordinator

What are the key responsibilities of a Production Engineering Tooling Coordinator?

The key responsibilities of a Production Engineering Tooling Coordinator include designing and developing production tooling, managing a team of tooling engineers, implementing tooling processes, and collaborating with manufacturing engineers to optimize tooling and manufacturing processes.

What are the required qualifications for a Production Engineering Tooling Coordinator?

The required qualifications for a Production Engineering Tooling Coordinator typically include a Bachelor’s degree in Mechanical Engineering or a related field, as well as experience in tool design, CAD/CAM, and metrology.

What are the career prospects for a Production Engineering Tooling Coordinator?

The career prospects for a Production Engineering Tooling Coordinator are excellent, with opportunities for advancement to senior-level positions in manufacturing and engineering.

What are the key skills required for a Production Engineering Tooling Coordinator?

The key skills required for a Production Engineering Tooling Coordinator include tool design, CAD/CAM, metrology, project management, problem-solving, and analytical skills.

What are the challenges faced by a Production Engineering Tooling Coordinator?

The challenges faced by a Production Engineering Tooling Coordinator include meeting production deadlines, optimizing tooling processes, and ensuring the quality of production tooling.

What are the qualities of a successful Production Engineering Tooling Coordinator?

The qualities of a successful Production Engineering Tooling Coordinator include strong technical skills, leadership abilities, project management skills, and a commitment to continuous improvement.