Are you a seasoned Production Line Technician seeking a new career path? Discover our professionally built Production Line Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

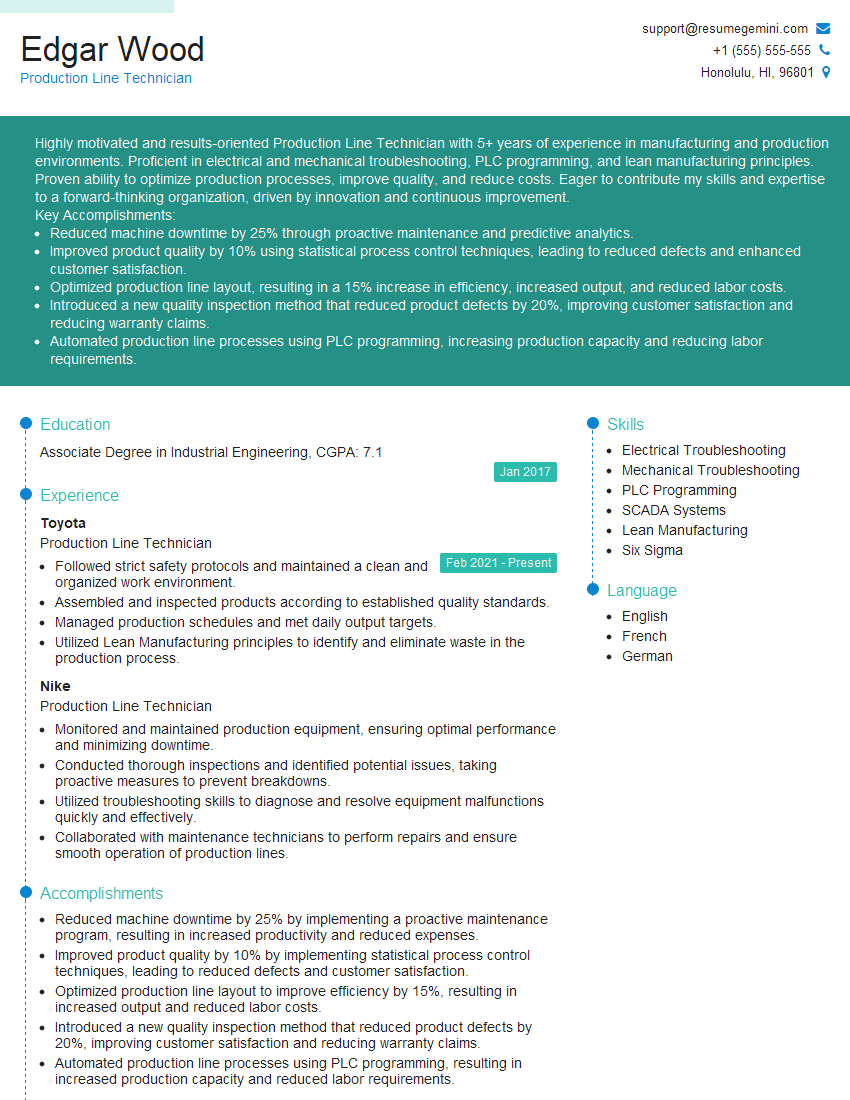

Edgar Wood

Production Line Technician

Summary

Highly motivated and results-oriented Production Line Technician with 5+ years of experience in manufacturing and production environments. Proficient in electrical and mechanical troubleshooting, PLC programming, and lean manufacturing principles. Proven ability to optimize production processes, improve quality, and reduce costs. Eager to contribute my skills and expertise to a forward-thinking organization, driven by innovation and continuous improvement.

Key Accomplishments:

- Reduced machine downtime by 25% through proactive maintenance and predictive analytics.

- Improved product quality by 10% using statistical process control techniques, leading to reduced defects and enhanced customer satisfaction.

- Optimized production line layout, resulting in a 15% increase in efficiency, increased output, and reduced labor costs.

- Introduced a new quality inspection method that reduced product defects by 20%, improving customer satisfaction and reducing warranty claims.

- Automated production line processes using PLC programming, increasing production capacity and reducing labor requirements.

Education

Associate Degree in Industrial Engineering

January 2017

Skills

- Electrical Troubleshooting

- Mechanical Troubleshooting

- PLC Programming

- SCADA Systems

- Lean Manufacturing

- Six Sigma

Work Experience

Production Line Technician

- Followed strict safety protocols and maintained a clean and organized work environment.

- Assembled and inspected products according to established quality standards.

- Managed production schedules and met daily output targets.

- Utilized Lean Manufacturing principles to identify and eliminate waste in the production process.

Production Line Technician

- Monitored and maintained production equipment, ensuring optimal performance and minimizing downtime.

- Conducted thorough inspections and identified potential issues, taking proactive measures to prevent breakdowns.

- Utilized troubleshooting skills to diagnose and resolve equipment malfunctions quickly and effectively.

- Collaborated with maintenance technicians to perform repairs and ensure smooth operation of production lines.

Accomplishments

- Reduced machine downtime by 25% by implementing a proactive maintenance program, resulting in increased productivity and reduced expenses.

- Improved product quality by 10% by implementing statistical process control techniques, leading to reduced defects and customer satisfaction.

- Optimized production line layout to improve efficiency by 15%, resulting in increased output and reduced labor costs.

- Introduced a new quality inspection method that reduced product defects by 20%, improving customer satisfaction and reducing warranty claims.

- Automated production line processes using PLC programming, resulting in increased production capacity and reduced labor requirements.

Awards

- Won Production Technician of the Month award for consistently exceeding production targets and maintaining a high level of quality.

- Received recognition for developing and implementing a training program for new production line employees, significantly reducing onboarding time and improving overall efficiency.

- Won recognition for outstanding safety performance, maintaining a clean and organized work environment and adhering to all safety protocols.

- Received recognition for innovative ideas and contributions to the continuous improvement of production line processes.

Certificates

- Certified Production Technician (CPT)

- PLC Certified Associate (PLCA)

- OSHA Safety Certification

- Lean Six Sigma Yellow Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Production Line Technician

Highlight your technical skills:

Production Line Technicians are responsible for maintaining and repairing complex machinery. Showcase your proficiency in electrical and mechanical troubleshooting, PLC programming, and SCADA systems.Quantify your accomplishments:

Use numbers and metrics to demonstrate the impact of your work. For example, instead of saying ‘improved production efficiency,’ say ‘increased production efficiency by 15%, resulting in a 10% reduction in labor costs.’Tailor your resume to the job description:

Carefully review the job description and highlight the skills and experience that are most relevant to the position you’re applying for.Proofread carefully:

Make sure your resume is free of errors in grammar, spelling, and formatting. A polished resume shows attention to detail and professionalism.

Essential Experience Highlights for a Strong Production Line Technician Resume

- Troubleshoot and repair electrical and mechanical systems on production lines, ensuring optimal performance and minimizing downtime.

- Implement and maintain preventive maintenance programs to prevent equipment failures and extend asset lifespans.

- Utilize PLC programming and SCADA systems to automate production processes, improve efficiency, and reduce labor requirements.

- Monitor production lines, identify bottlenecks, and implement lean manufacturing principles to optimize throughput and reduce waste.

- Conduct quality inspections, identify defects, and implement corrective actions to maintain high product quality standards.

- Collaborate with engineers and maintenance teams to identify and resolve complex production issues, ensuring smooth operations.

- Train and supervise junior technicians, fostering a culture of continuous improvement and knowledge sharing.

Frequently Asked Questions (FAQ’s) For Production Line Technician

What are the key responsibilities of a Production Line Technician?

Production Line Technicians are responsible for maintaining and repairing electrical and mechanical systems on production lines, implementing quality control measures, and optimizing production processes to ensure efficiency and quality.

What qualifications are required to become a Production Line Technician?

Most Production Line Technicians have an associate degree or diploma in industrial maintenance, electrical engineering, or a related field. Some employers may also require experience in a manufacturing or production environment.

What are the career prospects for Production Line Technicians?

Production Line Technicians can advance to supervisory roles, such as Production Supervisor or Maintenance Manager. With additional education and experience, they may also move into engineering or management positions.

What are the essential skills for a successful Production Line Technician?

Essential skills for Production Line Technicians include electrical and mechanical troubleshooting, PLC programming, SCADA systems, lean manufacturing principles, and quality control techniques.

What is the average salary for a Production Line Technician?

The average salary for a Production Line Technician in the United States is around $25,000 to $35,000 per year, depending on experience, location, and industry.

What is the job outlook for Production Line Technicians?

The job outlook for Production Line Technicians is expected to grow in the coming years, as businesses continue to invest in automation and efficiency.

What are the benefits of working as a Production Line Technician?

Benefits of working as a Production Line Technician include job stability, opportunities for advancement, and the chance to make a tangible contribution to the manufacturing process.